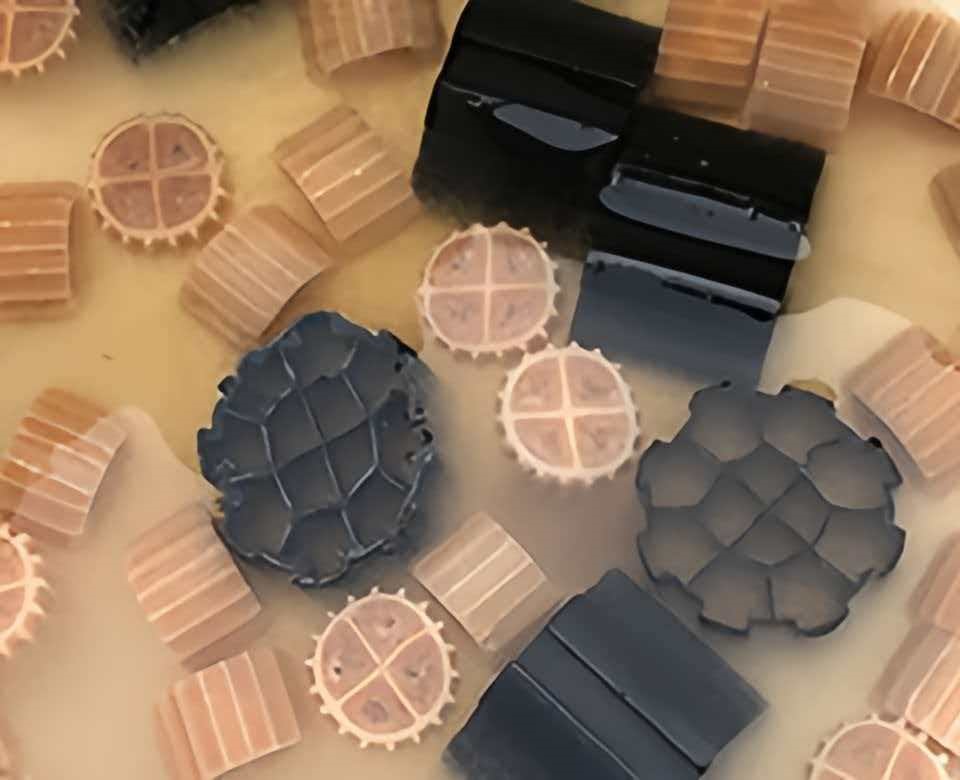

MBBR (Moving Bed Biofilm Reactor) media description

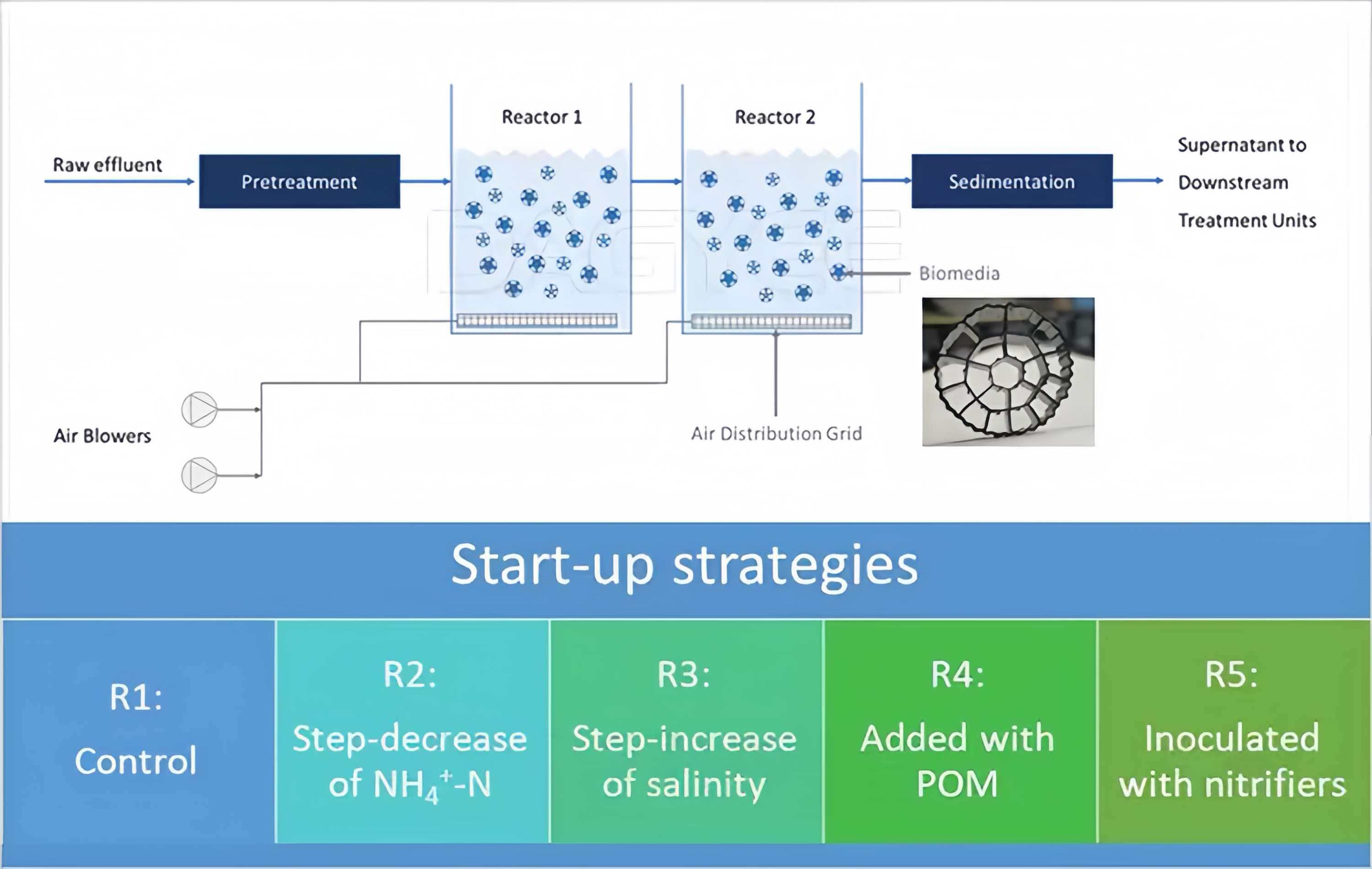

MBBR (Moving Bed Biofilm Reactor) Media represents a cutting-edge biological wastewater treatment technology that combines the advantages of conventional activated sludge processes with fixed-film biofilm systems.

These high-performance plastic carriers provide an immense protected surface area for the growth and attachment of beneficial microorganisms, forming a resilient biofilm that efficiently degrades organic pollutants, ammonia, and other contaminants.

The media's unique design allows it to move freely within the reactor tank, kept in constant motion by aeration or mechanical mixing, ensuring optimal contact between the biomass, wastewater, and oxygen.

This dynamic process creates an extremely robust and self-regulating ecosystem that adapts to fluctuating loads without requiring operator intervention.

MBBR systems are renowned for their compact footprint, operational simplicity, and exceptional treatment efficiency across a wide spectrum of applications, from municipal sewage plants to high-strength industrial effluent treatment.

The media itself is engineered from high-density polyethylene (HDPE) or similar durable polymers, designed to last decades while resisting abrasion, chemical corrosion, and UV degradation.

MBBR (Moving Bed Biofilm Reactor) media function

1. Biomass Immobilization & Biofilm Support

The primary function of MBBR media is to provide a stable, high-surface-area substrate for the immobilization of active biomass.

The intricate internal geometry of each carrier creates a vast protected environment (typically 500-1200 m²/m³) where bacteria, protozoa, and other microorganisms can colonize and form a thick, productive biofilm.

This fixed-film ecosystem is far more resilient than suspended flocs in conventional systems, protecting sensitive nitrifying and denitrifying bacteria from washout, toxicity, and shock loads.

2. Enhanced Mass Transfer & Oxygen Utilization

As the media circulates freely throughout the reactor, it continuously disrupts the boundary layer surrounding each biofilm, dramatically enhancing the mass transfer of substrates (BOD, COD, NH₃-N) into the biofilm and the diffusion of metabolic byproducts out.

Simultaneously, the tumbling action ensures efficient oxygen transfer from the fine-bubble aeration system directly to the microbial community. This dual enhancement maximizes reaction kinetics and treatment efficiency per unit volume.

3. Simultaneous Nitrification & Denitrification (SND)

The unique structure of the MBBR biofilm creates distinct aerobic, anoxic, and anaerobic micro-zones within its depth.

Oxygen penetrates only the outer layer, creating an aerobic zone for nitrification (conversion of ammonia to nitrate).

Deeper within the biofilm, where oxygen is depleted, an anoxic zone forms, facilitating denitrification (conversion of nitrate to nitrogen gas).

This allows for simultaneous removal of organic carbon and nitrogen in a single reactor, simplifying plant design and operation.

4. Self-Regulating Biomass Control & Sludge Reduction

The MBBR system features an intelligent, self-regulating biomass control mechanism.

As the biofilm grows thicker, the shear forces generated by media collision and water flow naturally slough off excess biomass, maintaining an optimal biofilm thickness for maximum activity.

This endogenous decay process minimizes the production of excess biological sludge (up to 30-50% less than activated sludge systems), significantly reducing sludge handling and disposal costs.

MBBR (Moving Bed Biofilm Reactor) media model K1 K3

| Parameter | Specification / Value |

|---|---|

| Porosity | 85% |

| Void Ratio | 15-65% |

| Biofilm Formation Time | 3-15 days |

| Pieces per m³ (approx.) | 400,000 - 1,200,000 / m³ |

| Applicable Temperature | 5-60°C |

| Service Life | > 15 years |

| Material | HDPE (High-Density Polyethylene) |

| Technical Parameter | Value / Specification |

|---|---|

| Specification Form | 10 ± 1 mm (after water absorption and expansion) |

| Density (absolutely dry) | 12.5 ± 0.75 kg/m³ |

| Accumulation Number | Approximately 500,000 / m³ |

| Specific Surface Area | > 2000 m²/m³ |

| Void | 98% |

| Allocation Rate | 25% - 72% |

| Time for Biofilm Attachment | 3 - 7 days |

| Nitrification Efficiency | 600-1250 g NH₃-N / m³ carrier · day |

| BOD₅ Oxidation Efficiency | 1000 - 5000 g BOD₅ / m³ carrier · day |

| COD Oxidation Efficiency | 1000 - 7500 g COD / m³ carrier · day |

| Biological Sludge | Approximately 5 - 20 kg SS / m³ carrier |

| Applicable pH | 6 - 10 |

| Applicable Temperature | 1 - 50°C |

| Service Life | > 10 years |

MBBR (Moving Bed Biofilm Reactor) media advantage

Exceptional Process Stability & Shock Load Resistance

The large, protected biomass inventory attached to the media is highly resistant to sudden changes in hydraulic or organic load, pH fluctuations, and the presence of toxic compounds.

The biofilm acts as a "biological buffer," ensuring consistent effluent quality even during storm events or industrial spills, where conventional systems would often fail.

Compact Footprint & High Volumetric Efficiency

MBBR technology achieves exceptionally high biomass concentrations (up to 30,000 mg/L) within the reactor, allowing for very high treatment capacity in a small space.

It can achieve the same treatment objective in as little as 20-30% of the volume required by conventional activated sludge tanks, making it ideal for plant upgrades within existing tankage or for space-constrained sites.

Operational Simplicity & Low Maintenance

The process is remarkably easy to operate.

There is no need for sludge recirculation, complex clarifier control, or frequent biomass monitoring.

The system is largely self-regulating.

Maintenance is minimal, primarily involving standard aeration system checks and occasional media inspection, leading to reduced labor and operational expertise requirements.

Energy Efficiency & Reduced Aeration Costs

The efficient oxygen transfer facilitated by the moving media, combined with the high metabolic activity of the biofilm, leads to lower specific aeration energy demand per kg of pollutant removed.

Furthermore, the reduced sludge production lowers energy consumption associated with sludge pumping, thickening, and dewatering.

Modularity & Easy Scalability

MBBR systems are inherently modular.

Treatment capacity can be easily increased by simply adding more media to an existing tank or adding additional MBBR reactor trains.

This "plug-and-play" scalability offers unparalleled flexibility for phased expansions or for handling future increases in wastewater flow and load.

No Clogging & No Channeling

Unlike fixed-bed filters (e.g., trickling filters), the continuous motion of the media prevents clogging from accumulated solids or excessive biofilm growth.

The random movement also eliminates the problem of channeling, where wastewater finds a path of least resistance, ensuring that all media and biomass are uniformly utilized for treatment.

MBBR (Moving Bed Biofilm Reactor) media feature

Advanced Geometric Design with Internal Cross-Flow Channels

Our media features a patented internal lattice structure with multiple cross-flow channels.

This design maximizes the protected surface area while promoting turbulent water flow through the media, not just around it.

This internal turbulence is critical for delivering nutrients and oxygen to the innermost layers of the biofilm, preventing the formation of inactive, stagnant zones.

High-Density Polyethylene (HDPE) Construction with UV Stabilizers

Manufactured from virgin, food-grade HDPE, the media is chemically inert, non-toxic, and resistant to all chemicals found in typical wastewater.

It includes integrated UV stabilizers to prevent polymer degradation from sunlight during storage or in open tanks, guaranteeing a service life exceeding 20 years.

Optimized Density for Perfect Suspension & Mixing

The media's specific gravity is engineered to be slightly less than water (approx. 0.96-0.98 g/cm³).

This precise buoyancy ensures the carriers are kept in perfect, homogenous suspension with minimal energy input from the aeration system, achieving complete reactor volume utilization without dead zones.

Smooth External Surface with Anti-Abrasion Profile

While the interior is complex, the external surface features a smooth, rounded profile.

This minimizes abrasive wear during media-to-media and media-to-tank collisions over decades of operation, preventing the generation of plastic fines that could escape the system.

Biofilm-Promoting Micro-Texture

A specialized manufacturing process creates a microscopically textured surface on the internal structures.

This texture significantly enhances the initial attachment and colonization rate of bacteria, reducing system start-up time and improving biofilm adhesion strength under varying conditions.

Integrated Sieve Retention System Compatibility

The media is designed to work seamlessly with standard retention sieves (typically with 5-7 mm apertures).

Its size and shape are optimized to be perfectly retained within the reactor while allowing treated water and excess biomass to pass freely, ensuring zero media loss.

MBBR (Moving Bed Biofilm Reactor) media appliacation

Municipal Wastewater Treatment (Greenfield & Retrofit)

Ideal for new municipal plants or for upgrading overloaded existing activated sludge or trickling filter plants.

MBBR can be used for BOD/COD removal, nitrification, denitrification, or as a hybrid system.

It allows communities to increase capacity by 300-400% within existing tank footprints, deferring massive capital investments in new concrete tanks.

Industrial Wastewater Treatment (High-Strength & Complex)

Widely used in industries such as food & beverage (dairies, breweries, slaughterhouses), pharmaceuticals, petrochemicals, and pulp & paper.

Its robustness handles high, variable organic loads and toxic shocks.

Specific strains of bacteria can be nurtured on the media to bio-degrade complex, recalcitrant compounds.

Aquaculture & Recirculating Aquaculture Systems (RAS)

Critical for maintaining water quality in intensive fish and shrimp farming.

MBBR provides highly stable biofiltration for the removal of toxic ammonia and nitrite (via nitrification) in RAS.

Its compact size and reliability are essential for land-based and offshore aquaculture operations.

Leachate Treatment from Landfills

Landfill leachate is a challenging wastewater with high ammonia, heavy metals, and refractory organics. MBBR systems, often in multiple stages, are highly effective for stabilizing and treating leachate.

The robust biofilm withstands the toxic and variable nature of the leachate, providing a reliable pretreatment before reverse osmosis or other polishing steps.

Marine & Shipboard Sewage Treatment (MARPOL Compliance)

Used in compact, packaged sewage treatment plants for cruise ships, cargo vessels, and offshore platforms.

The MBBR's small size, low sludge production, and ability to handle rolling and pitching motions make it the leading biological technology for meeting stringent international MARPOL discharge standards at sea.

Decentralized & Rural Community Wastewater Systems

Perfect for small communities, resorts, hotels, and remote installations where central sewerage is unavailable.

Pre-fabricated MBBR packaged plants offer a "set-and-forget" solution with minimal operational demands, producing high-quality effluent suitable for surface discharge or reuse for irrigation.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China