Compact Units Pretreatment Plants For Wastewater Treatment Description

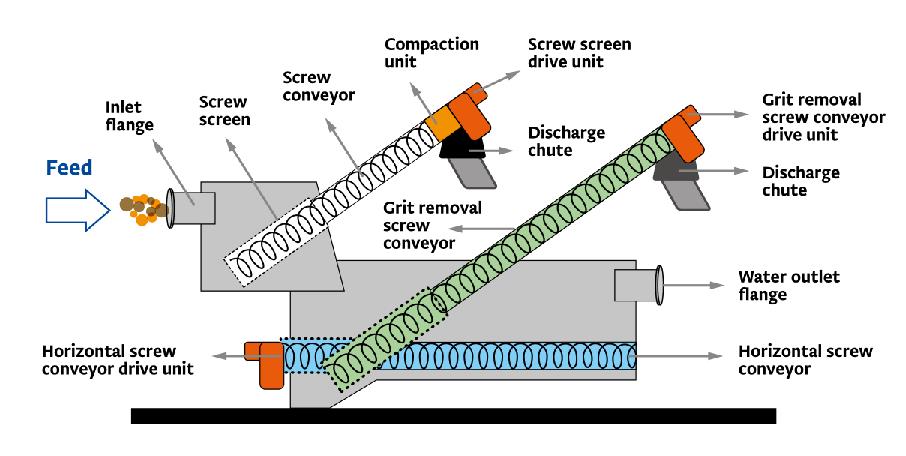

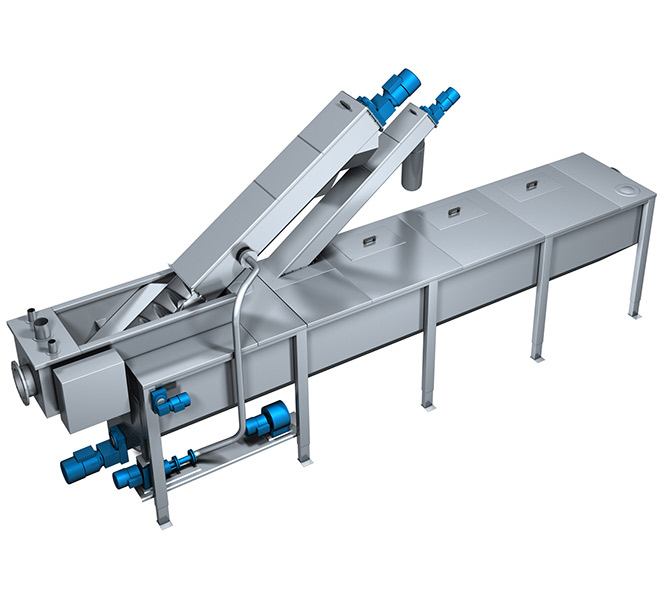

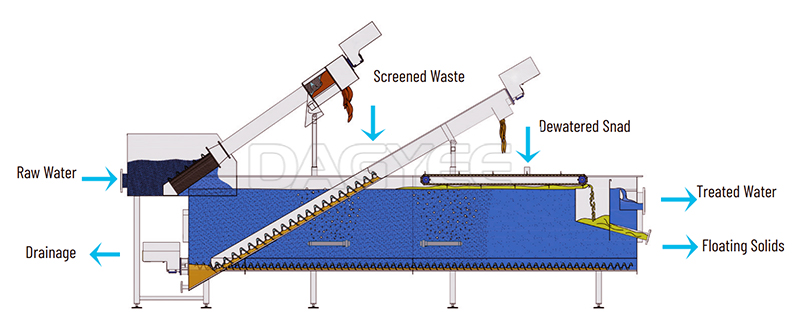

This Combined Pretreatment Compact Unit equipment is fed by a pump or to gravity, through a fixed pipe. The effluent passes through a screw screen that removes the most large solid particles, then goes to a sedimentation tank where the particles sedimented are then removed by a system of scews. As an option you can install the system for removal of fats and suspended oils.

Combined Screening Component

Dependable, complete and compact unit Performing the following process steps:

Combined Screening Working Principle

For the removal of suspended particles such as oil, grease, and other substances, the unit employs a system of paddles made from stainless steel wire. The settling tank is equipped with an air blower to further facilitate the separation of organic matter and the settlement of grit. Larger units may be fitted with two blowers for increased efficiency.Screening and compacting

The solids are retained by the grid and then extracted and conveyed by the screw to the compaction zone. The compaction can be integrated into the screening machine, or carried out by an Enviropac transversal compactor equipped with an innovative and specific back pressure system to adjust the dryness.

Filtration screen

The bubbles formed by an air insufflation ensure the separation of the fat by flotation and separate the organic materials stuck to the sand. The sand and fat removing tank is designed by modules of identical lengths. This modularity offers a great flexibility. It is thus possible to vary, at the origin or later on, the length of the tank to adapt to the desired hydraulic speeds.

Fat extraction

The extraction of fat takes place over the entire length of the machine by means of a longitudinal box. The accumulation of fat in this zone is favored by the movement created by the insufflation of air. The fat is recovered and evacuated by a surface scraper.

Sand extraction

The decanted sand is collected by a first horizontal screw installed at the bottom of the tank, and is transferred to an extraction and draining screw for evacuation towards storage systems before final disposal.

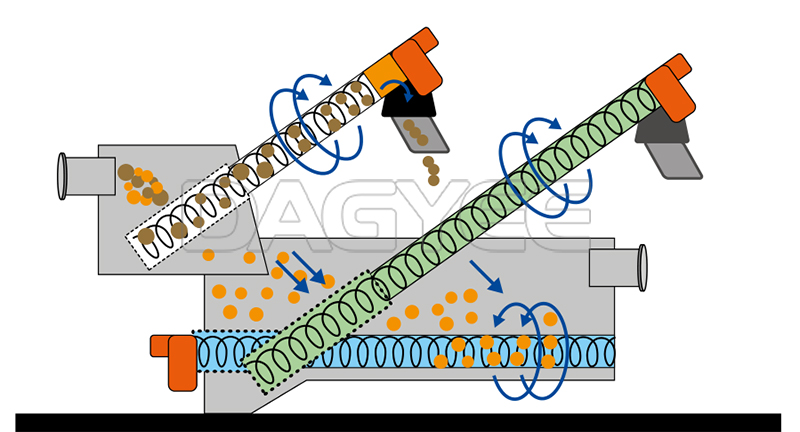

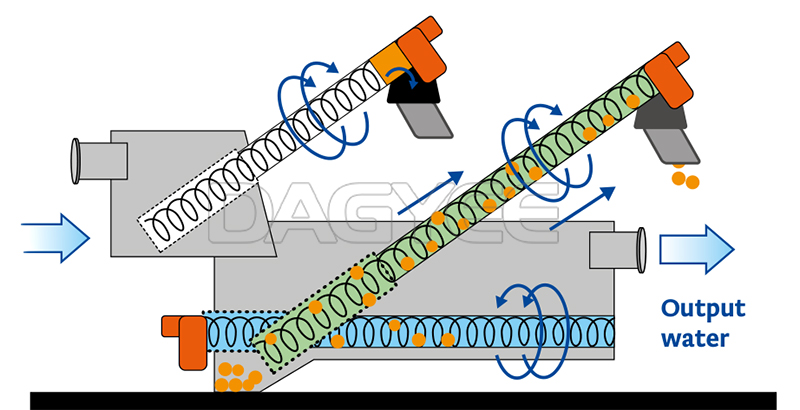

The wastewater firstly enters the tank where a screw screen is placed.

Big size solid materials are filtrated by the screw screen and a screw conveyor moves the solid materials captured up to the discharge point. At the end of the conveyor, they are pressed by the compaction unit before discharge.

The water which has still solid materials in smaller sizes flows through the sedimentation tank. The particles are settled by time and a horizontal screwconveyor transports them to the collection hopper.

Finally, they are conveyed by the grit removal screw conveyor to the discharge point.

Combined Screening Parameter

| Power Specifications | ||||||

| Model | Capacity (m3/h) | Tank Length(mm) | Tank Width(mm) | Inlet Flange DN | Outlet Flange DN | Max.Wash Water(L/S) |

| DSP-30 | 30 | 4200 | 1200 | DN200 | DN200 | 0.5 |

| DSP-50 | 50 | 5800 | 1200 | DN200 | DN200 | 0.5 |

| DSP-100 | 100 | 7000 | 1200 | DN250 | DN250 | 1 |

| DSP-150 | 150 | 7000 | 1200 | DN250 | DN250 | 1 |

| DSP-200 | 200 | 8000 | 1500 | DN300 | DN300 | 1 |

| DSP-250 | 250 | 8500 | 1500 | DN350 | DN350 | 1 |

| DSP-350 | 350 | 10000 | 1500 | DN400 | DN400 | 1 |

| DSP-400 | 400 | 12000 | 1800 | DN500 | DN500 | 1 |

| DSP-500 | 500 | 15000 | 2000 | DN500 | DN500 | 1 |

| Power Specifications | ||||

| Model | Screw Screen Power(kw) | Screw Conveyor Power(kw) |

Grit Removal

Power(kw)

|

Grease Removal

Power(kw)

|

| DSP-30 | 0.55 | 0.25 | 0.37 | 0.18 |

| DSP-50 | 0.55 | 0.35 | 0.37 | 0.18 |

| DSP-100 | 0.75 | 0.37 | 0.55 | 0.18 |

| DSP-150 | 0.75 | 0.37 | 0.55 | 0.18 |

| DSP-200 | 0.75 | 0.55 | 0.75 | 0.18 |

| DSP-250 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-350 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-400 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-500 | 1.1 | 0.55 | 1..1 | 0.18 |

Combined Screening Features

Combined Screening Advantages

Combined Screening Applications

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China