Compact Units Pretreatment Plants For Wastewater Treatment Description

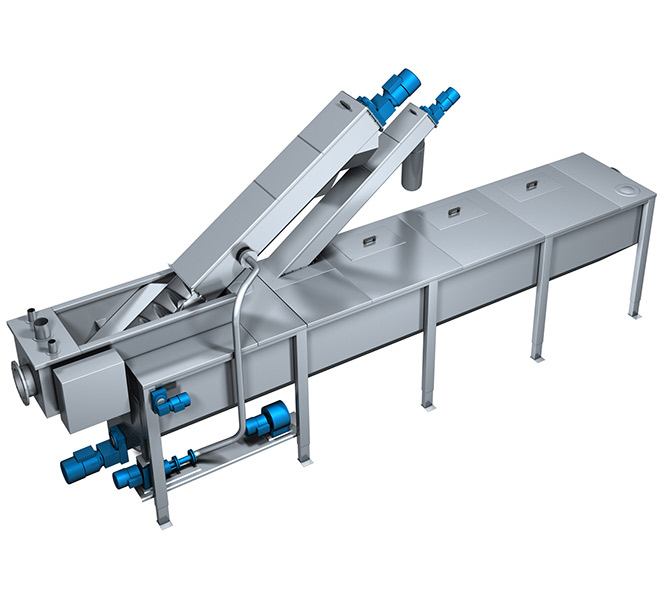

The compact preatreatment unit is machine-welded in stainless steel with three fucntions, screening, sand removal, and fat removal of raw effluents. DAGYEE units are designed to accept flows from 10 up to 500 m3/hr, but several units can be installed in parrallel to accept flow variation due to seasonality or to higher flow. An efficient screening is performed with a Spirascreen adapted to each model. Sand and fat removalis performed inside a longitudinal tank in continuation to the screening phase.

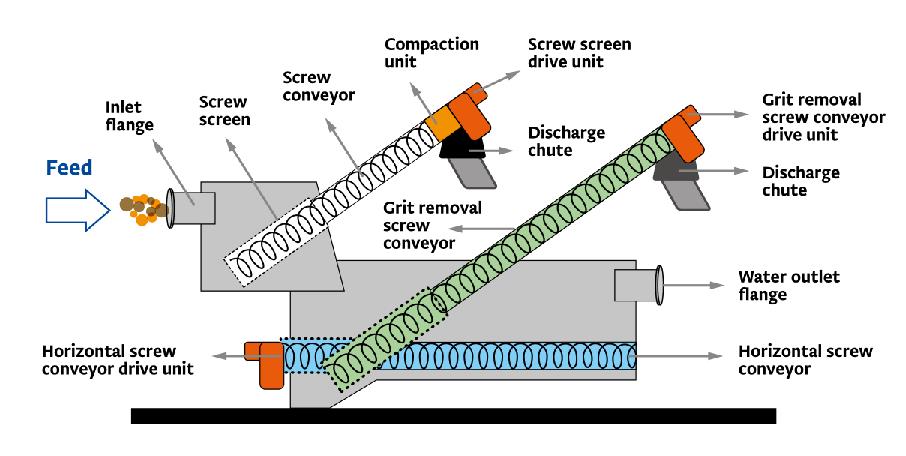

Combined Screening Component

Dependable, complete and compact unit Performing the following process steps:

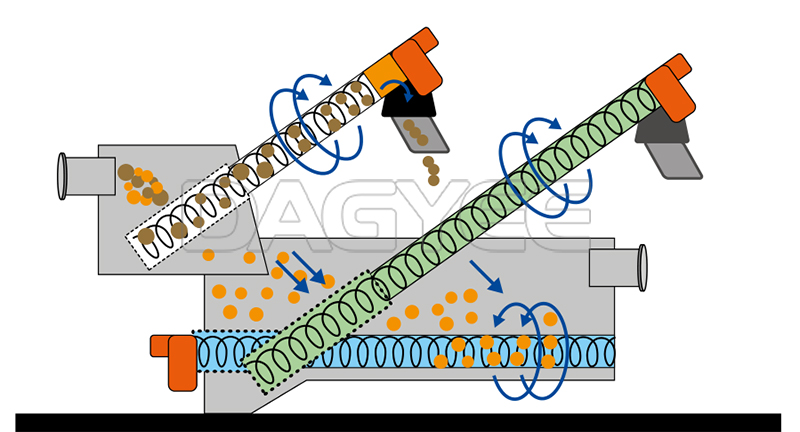

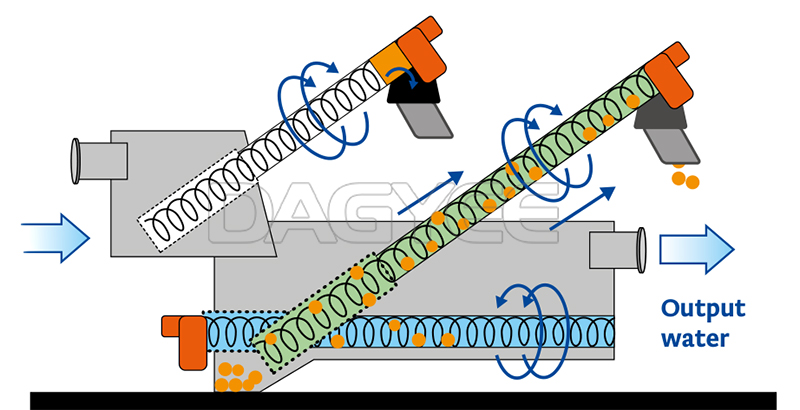

Combined Screening Working Principle

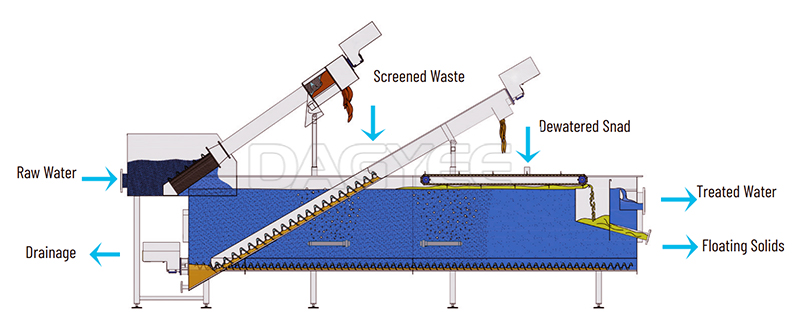

Many wastewater treatment plants process municipal, industrial and septic tank sludges that contain debris and inorganic solids such as hair, plastics, grease and hygienic materials. This debris can negatively impact downstream equipment by clogging pumps and valves, decreasing the effectiveness of aeration, dewatering and filtering equipment. Ecologix sewage acceptance systems are fully automated and designed to remove debris and inorganic solids that typically pass through a conventional bar screen. Initially, wastewater is screened to remove large particles which are then washed to remove organic matter and compacted before being discharged. The screened wastewater then flows into the sedimentation tank, where grit settles into a hopper and is subsequently extracted by an inclined screw conveyor. Water treated in these units typically achieves TSS of <500 mg/L and 95% removal of grit material.

The wastewater firstly enters the tank where a screw screen is placed.

Big size solid materials are filtrated by the screw screen and a screw conveyor moves the solid materials captured up to the discharge point. At the end of the conveyor, they are pressed by the compaction unit before discharge.

The water which has still solid materials in smaller sizes flows through the sedimentation tank. The particles are settled by time and a horizontal screwconveyor transports them to the collection hopper.

Finally, they are conveyed by the grit removal screw conveyor to the discharge point.

Combined Screening Parameter

| Power Specifications | ||||||

| Model | Capacity (m3/h) | Tank Length(mm) | Tank Width(mm) | Inlet Flange DN | Outlet Flange DN | Max.Wash Water(L/S) |

| DSP-30 | 30 | 4200 | 1200 | DN200 | DN200 | 0.5 |

| DSP-50 | 50 | 5800 | 1200 | DN200 | DN200 | 0.5 |

| DSP-100 | 100 | 7000 | 1200 | DN250 | DN250 | 1 |

| DSP-150 | 150 | 7000 | 1200 | DN250 | DN250 | 1 |

| DSP-200 | 200 | 8000 | 1500 | DN300 | DN300 | 1 |

| DSP-250 | 250 | 8500 | 1500 | DN350 | DN350 | 1 |

| DSP-350 | 350 | 10000 | 1500 | DN400 | DN400 | 1 |

| DSP-400 | 400 | 12000 | 1800 | DN500 | DN500 | 1 |

| DSP-500 | 500 | 15000 | 2000 | DN500 | DN500 | 1 |

| Power Specifications | ||||

| Model | Screw Screen Power(kw) | Screw Conveyor Power(kw) |

Grit Removal

Power(kw)

|

Grease Removal

Power(kw)

|

| DSP-30 | 0.55 | 0.25 | 0.37 | 0.18 |

| DSP-50 | 0.55 | 0.35 | 0.37 | 0.18 |

| DSP-100 | 0.75 | 0.37 | 0.55 | 0.18 |

| DSP-150 | 0.75 | 0.37 | 0.55 | 0.18 |

| DSP-200 | 0.75 | 0.55 | 0.75 | 0.18 |

| DSP-250 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-350 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-400 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-500 | 1.1 | 0.55 | 1..1 | 0.18 |

Combined Screening Features

Combined Screening Advantages

Combined Screening Applications

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China