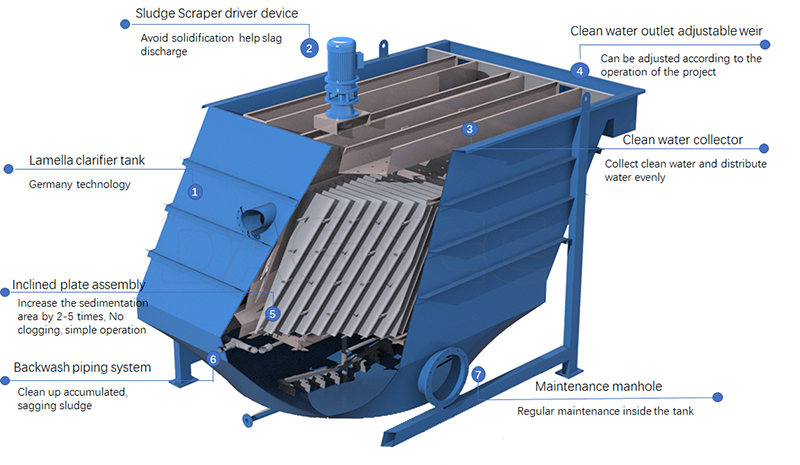

Inclined Plate Clarification Clarifier Description

A inclined plate clarification clarifier differs from a conventional clarifier by the presence of inclined plates that increase the settling surface. This allows for faster and more efficient clarification while occupying less floor space. On average, a lamella clarifier is 10 times more efficient than a conventional clarifier for separating suspended particles, thanks to a better Hazen velocity and an optimized sludge index.

Inclined Plate Clarification Clarifier Principle

Inclined Plate Clarification Clarifier Model

DLC-I Gravity Lamella, V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

DLC

Model

Capacities

(m3/h)

Piping Connections()

Physical Dimensions(m)

Inlet(a)

Effluent(b)

Sludge(c)

Backwash(d)

L

W

H

DLC-

5

80

80

50

50

2.55

1.6

2.9

DLC-

10

100

100

50

50

3.35

1.82

3

DLC-

15

100

100

50

50

3.35

2.02

3

DLC-

20

100

100

50

50

3.35

2.02

3

DLC-

30

150

150

50

50

4.2

2.22

3

DLC-

40

150

150

50

50

4

2.8

3

DLC-

50

200

200

50

50

4.65

2.82

3

DLC-

60

200

200

50

50

4.7

3

3

DLC-

70

250

200

50

50

6.4

2.6

3

DLC-

80

250

200

50

50

6.8

2.82

3

DLC-

100

250

250

50

50

7.05

3.02

3

Inclined Plate Clarification Clarifier Characteristics

Inclined Plate Clarification Clarifier Applications

Textile Industry

In the textile industry, lamella clarifiers are used to treat dye-bath effluents. These effluents often contain high levels of suspended solids and colloidal particles. Lamella clarifiers, combined with anionic polymers and coagulants, can effectively separate these particles, achieving a TSS removal efficiency of up to 84%.

Food and Beverage Industry

In the food and beverage industry, lamella clarifiers are used to treat wastewater containing high levels of suspended solids and organic matter. The compact design and high efficiency of lamella clarifiers make them ideal for facilities with limited space. They can achieve a TSS removal efficiency of up to 90%, significantly reducing the turbidity of the effluent.

Stormwater Management

Lamella clarifiers can be integrated into stormwater treatment systems to effectively remove solids and pollutants before discharge into natural water bodies. This is particularly important in urban areas where stormwater runoff can carry a significant amount of pollutants.

Plating and Finishing Wastes

In the plating and finishing industry, lamella clarifiers are used to treat wastewater containing heavy metals and other hazardous substances. The efficient solid-liquid separation provided by lamella clarifiers ensures that these pollutants are effectively removed, meeting regulatory standards for safe discharge.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China