Lamella Plate System Description

Lamella plate systems are an integral component of modern wastewater treatment processes, enhancing sedimentation efficiency through an innovative design that optimizes the separation of solid particles from the liquid.

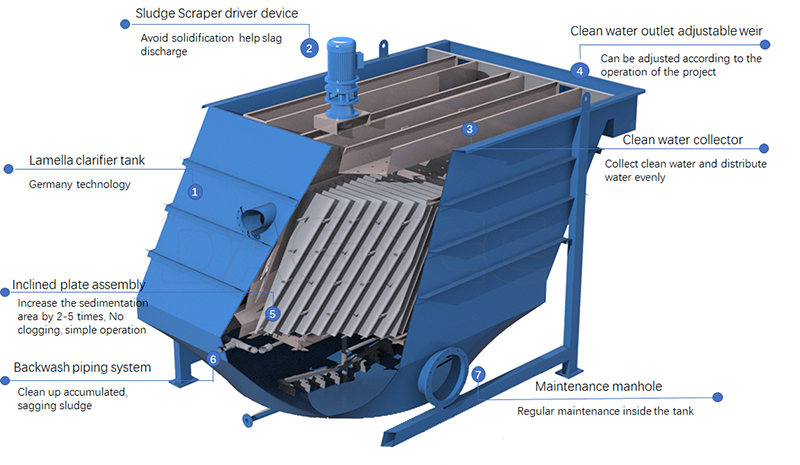

Lamella Plate System Structures

Lamella Plate System Model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

DLC

Model

Capacities

(m3/h)

Piping Connections()

Physical Dimensions(m)

Inlet(a)

Effluent(b)

Sludge(c)

Backwash(d)

L

W

H

DLC-

5

80

80

50

50

2.55

1.6

2.9

DLC-

10

100

100

50

50

3.35

1.82

3

DLC-

15

100

100

50

50

3.35

2.02

3

DLC-

20

100

100

50

50

3.35

2.02

3

DLC-

30

150

150

50

50

4.2

2.22

3

DLC-

40

150

150

50

50

4

2.8

3

DLC-

50

200

200

50

50

4.65

2.82

3

DLC-

60

200

200

50

50

4.7

3

3

DLC-

70

250

200

50

50

6.4

2.6

3

DLC-

80

250

200

50

50

6.8

2.82

3

DLC-

100

250

250

50

50

7.05

3.02

3

Lamella Plate System Advantages

The lamellar decanter provides a better sludge index by effectively separating suspended particles. The inclined plates facilitate slow water flow. Each suspended particle has enough time to accumulate on the surface.

Moreover, lamella clarifiers provide a lower Hazen speed than other types of clarifiers. This Hazen velocity is an indicator of the quality of clarified water, and the lower it is, the clearer the water. It is measured by the sludge index.

Another benefit of a lamella clarifier is its simplicity of use and maintenance. The lamellae can easily be cleaned and the sludge is removed by a draining system.

Ultimately, the lamella clarifier is a reliable clarification system for a variety of applications. Suitable for wastewater treatment plants, industries and fish farms.

Lamella Plate System Applications

Inorganic Salts: It is the largest group of inorganic compounds. These include potassium, sodium, lithium, copper, magnesium, calcium, barium iron, tin or ammonium and compounds derived from these. As well as chlorides, nitrates, sulfates, phosphates, carbonates, bromides, iodides, fluorides, sulphides, nitrites or phosphides.

Battery Materials: The production of batteries is a complex process that requires a variety of raw materials and processes. Lithium-ion batteries, which are used in many electronic devices, require lithium, cobalt, nickel, copper and aluminum as the main raw materials.

Fertilizers: We mainly process mineral fertilizers of inorganic origin with our machines. Potassium or magnesium salts from mining or brine processes, or phosphates, nitrates and nitrites.

Polymers & Bio-Polymers: The polymer industry offers us a broad and constantly challenging range of applications. We offer solutions for solid-liquid separation, thermal drying, control sieving and sampling, among others.

Food & Dairy: A leader in the development and supply of centrifuges for food and dairy production for more than 70 years. Especially in the production of lactose for baby food and pharmaceutical lactose, our machines represent the state of the art. See for yourself!

Organic Chemicals: Organic chemicals cover a wide range of compounds, including hydrocarbons such as alkanes, alkenes, and alkynes; aromatic compounds such as benzene and its derivatives; and complex molecules such as proteins, carbohydrates, and nucleic acids.

Minerals & Mining: These include coal, all types of sand, gravel, grit, salts, earth and ores. Our machines are key equipment in a wide variety of processes. They are used for processing, solid-liquid separation, screening, sampling and sample preparation, as well as for analysis and quality assurance.

Recycling & ZLD: For decades, the global scarcity of resources and raw materials has led to the sustainable activation of recyclable materials that are fed back into the value chain. Through recycling & ZLD, we can conserve valuable resources, reduce the need for new raw materials, minimize waste, save energy and reduce greenhouse gas emissions.

Other Industries: The list of industries and applications for our process solutions is long. We have only listed those in which we have the most experience. If you are missing something, it does not mean that we do not have a solution for your task.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China