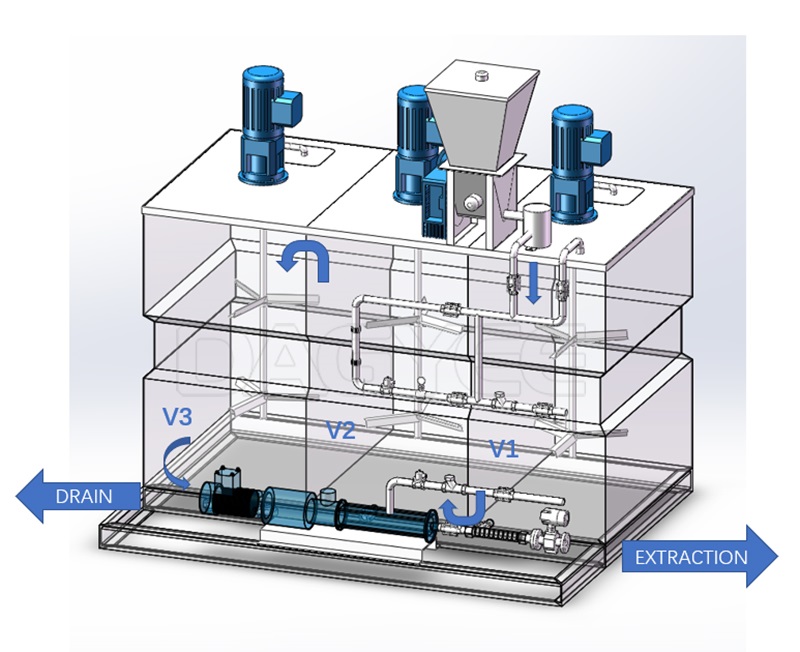

The DAGYEE unit provides automatic and continuous preparation of the polymer solution using a constant and uniform quality, resulting from:

One two-impeller mixer located in the preparation compartment (single impeller in the maturation compartment),

Optimized maturation cycles.

By fitting with an optional dilution unit, the main solution can then be diluted.

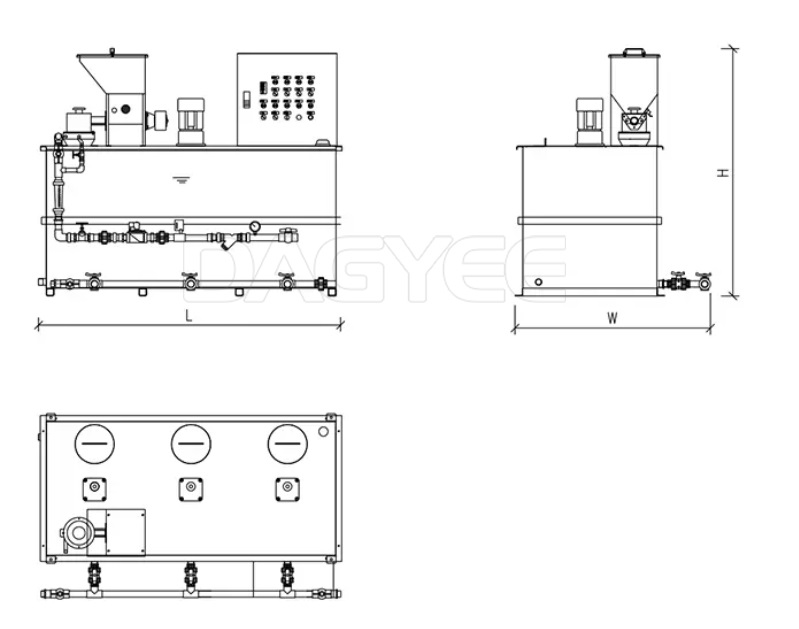

Polymer Dosing System has treee comparments. The first one is preparation compart- ment, the second one is ageing department and the last one is storage compartment. These three parts are seperated from easch orher by welded plates. Polymer Storage and feeding hooper is a steel small tank in which polyelectrolyte is stored. Polyelectrolyte in this hoop- er doses by the mounted feeding screw bottom of the hooper. There are two mixers in the unit. In the first compartment, there is a rapid mixer used for polyelectrolyte prepration and in the second compartment, slow mixer for ageing. Units can be manufactured in different capacities depending on the requirements.

Polymer preparation unit model

| Model | Capacity L/H | Volume L | Timing H | Dimensions MM | Weight KG | Power KW |

|---|---|---|---|---|---|---|

| DT300 | 300 | 450 | 0.6-1 | 1500*1000*500 | 300 | 1.8 |

| DT500 | 500 | 750 | 0.6-1 | 1500*1000*650 | 420 | 1.8 |

| DT1000 | 1000 | 1500 | 0.6-1 | 2000*1000*900 | 500 | 2.8 |

| DT1500 | 1500 | 2250 | 0.6-1 | 2000*1200*900 | 620 | 3 |

| DT2000 | 2000 | 3000 | 0.6-1 | 2500*1200*1000 | 800 | 3.9 |

| DT3000 | 3000 | 4500 | 0.6-1 | 3000*1500*1000 | 950 | 5.3 |

| DT5000 | 5000 | 7500 | 0.6-1 | 5000*1500*1000 | 1250 | 7 |

| DT10000 | 10000 | 15000 | 0.6-1 | 4800*1800*2000 | 3600 | 7 |

■ Easy to operate, labor saving

Precast mixing tank, homogeneous slaking tank and solution storage tank are in one equipment, easy to learn and easy to operate, saving labor.

■ Polymer concentration is adjustable

Water and polymer can get into the tank at the same time, as the flowing rate of the feeding pump can be controlled, so any concentration (within a certain range) can be prepared according to the actual requirements.

Fully automated, continuous 24/7 operation with stable concentration output

Suitable for polymer powders and liquids, with separate feed lines

Applicable across sectors – wastewater, mining, oil & gas, chemical processing

No dedicated operator required – only ~30 min/day for refilling and inspection

Zero powder loss – 100% utilization of polymer without waste

Polymer preparation unit application

Chemical Treatment Systems

Industrial Wastewater Treatment Systems

– Grease Industries

– Sugar Industries

– Leather Industries

Wastewater Treatment Systems

Filtration Systems

Sludge Dewatering;

– Conditioning Chemical or Excess Biological Sludge

Contact us:

Company: Wuxi Dajiang Environmental Technology Co., Ltd. DAGYEE

Phone/WhatsApp:+8613961861780

Email: info@dagyee.com

Website: www.dagyee.com

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China