Static Mixers

A static mixer is a device for the continuous mixing of fluid materials, without moving components. Normally the fluids to be mixed are liquid, but static mixers can also be used to mix gas streams, disperse gas into liquid or blend immiscible liquids. The energy needed for mixing comes from a loss in pressure as fluids flow through the static mixer. One design of static mixer is the plate-type mixer and another common device type consists of mixer elements contained in a cylindrical (tube) or squared housing. Mixer size can vary from about 6 mm to 6 meters diameter. Typical construction materials for static mixer components include stainless steel, polypropylene, Teflon, PVDF, PVC, CPVC and polyacetal. The latest designs involve static mixing elements made of glass-lined steel.

Static Mixer Function

In case of two miscible liquids in laminar flow, the main mechanism in a static mixer is flow division. The elements are helical or pseudo-helical and are arranged in a series of alternating left and right hand 180 twists. The elements split the fluids entering in two streams and than rotate them through 180 degrees. The elements are in series in the mixer. As the number of streams or layers increases, the layer thickness decreases. Typically, 12 to 24 elements are required to provide a complete mix.

In case of two miscible liquids in a turbulent flow, the main mechanism is radial mixing: fluids are constantly moved from the pipe centre to the pipe walls and the fluid change direction with each succeeding element. To achieve a fully homogeneous mix in a turbulent flow 1.5 to 4 elements are sufficient.

In case of two immiscible liquids in a turbulent flow, the radial mixing mechanism reduces radial differences in velocity and in droplet sizes. This raises the surface area of contact between phases, improving the mixing. The disperser length necessary depends on the required contact time. For mass transfer processes in which equilibrium is quickly established, a length of 5 diameters is generally sufficient.

Static Mixer SK Series Model

|

Model |

Dg(mm) |

dh(mm) |

Q(m3/h) |

|

SK-5/10 |

10 |

5 |

0.15-0.3 |

|

SK-7.5/15 |

15 |

7.5 |

0.3-0.6 |

|

SK-10/20 |

20 |

10 |

0.6-1.2 |

|

SK-12.5/25 |

25 |

12.5 |

0.9-1.8 |

|

SK-16/32 |

32 |

16 |

1.4-3.2 |

|

SK-20/40 |

40 |

20 |

2.2-4.5 |

|

SK-25/50 |

50 |

25 |

3.5-7.0 |

|

SK-32.5/65 |

65 |

32.5 |

5.9-12 |

|

SK-40/80 |

80 |

40 |

9-18 |

|

SK-50/100 |

100 |

100 |

14-28 |

|

SK-62.5/125 |

125 |

125 |

22-44 |

|

SK-75/150 |

150 |

150 |

31-64 |

|

SK-100/200 |

200 |

200 |

56-110 |

|

SK-125/250 |

250 |

250 |

88-177 |

|

SK-150/300 |

300 |

300 |

127-255 |

|

SK-175/350 |

350 |

350 |

173-346 |

|

SK-200/400 |

400 |

400 |

226-452 |

|

SK-250/500 |

500 |

500 |

353-706 |

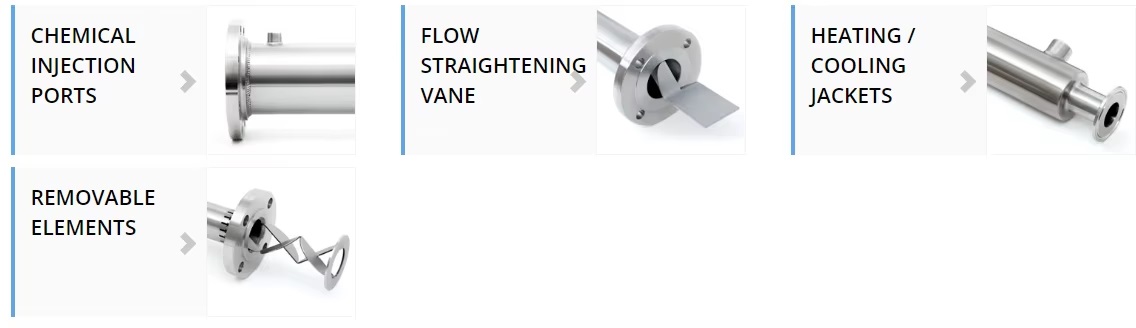

Static Mixer Options

Static Mixer Benefits

Maintenance-Free

DAGYEE Static Mixers are built to last using industrial grade materials specifically tailored to your application.

Low Energy Requirements

Because static mixers are motionless by design, all the energy required to provide a perfect blend is provided by the energy of the flow stream.

Custom-Designed for Your Application

All DAGYEE Static mixers can be custom-tailored to fit your requirements.

Low-Cost

DAGYEE Static Mixers are a low-cost alternative to traditional tank mixers both at purchase and during the mixer's lifetime. There are no running costs associated with operating a DAGYEE Static Mixer on top of running your existing pipeline.

No Moving Parts

Unlike traditional mixers, static mixers remain motionless during the mixing process.

Quick Delivery

DAGYEE maintains complete control over its production process. All static mixers are built in-house at DAGYEE's manufacturing facility outside Chicago and can be manufactured to meet your project schedule.

Static Mixer Applications

Plastic or PVC Mixers are used in the Water Industry and in General industry but can only tolerate Low Temperatures, they operate the same as the metal Static Mixers, PTFE Mixers can be used in the Chemical or Pharmaceutical applications for corrosive Chemical Additions at up to 200°C approx.

How popular are stainless steel static mixers?

Stainless Steel Static Mixers are used in the Chemical and Pharmaceutical Industries where the material is compatible with the process, they are also used in the Water Industry but again only where the process media is compatible with Stainless Steel, in the main, Coated Static Mixers are used in the Water Industry because they are compatible with almost all chemicals and acids, the coating used is made from Plant based materials and is approved by the UK DWI for use in Drinking Water (Potable Water) applications, the Coatings are Rilsan and Scotchcoat and are applied by Electrostatic means in a powder bed, the Mixer Housing with Element is dipped into the Powder Bed and the Coating is Electrostatically applied.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China