A belt filter press (BFP) provides sludge dewatering by pressing the sludge to force the water through a permeable medium. The process produces a cake (the dewatered product) having a dry solids (DS) content of 30% or more in the case of primary sludge. This is to be distinguished from the lower-energy gravity belt thickener process which achieves a maximum DS content of ~10%.

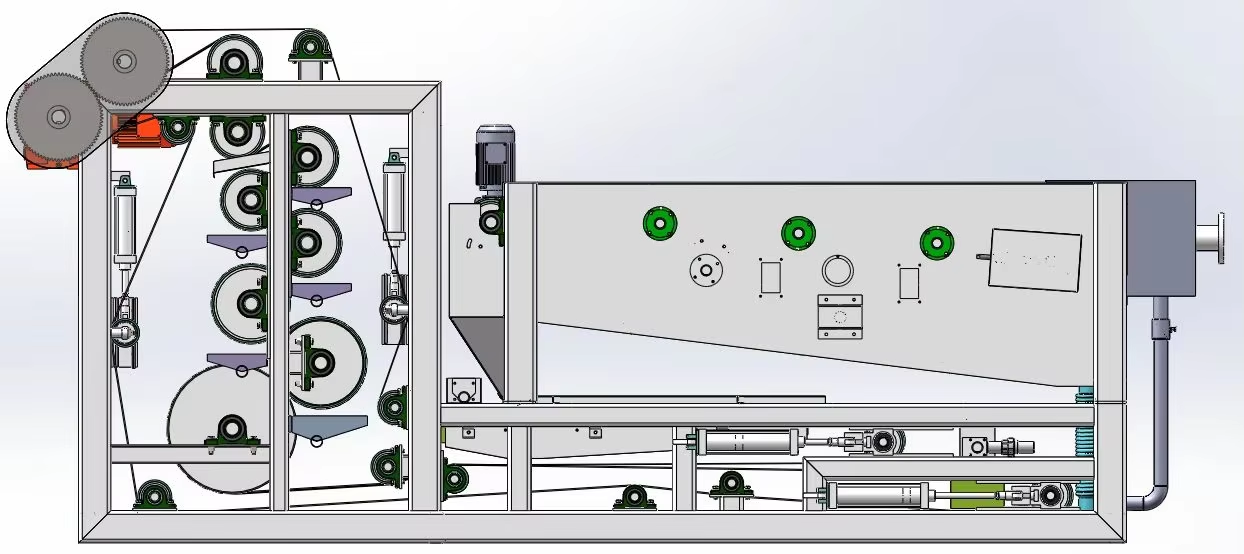

A BFP combines drainage and mechanical pressure sequentially to remove water. The equipment normally comprises 2−3 recirculating belts, with two belts combining at some point to compress the sludge and squeeze water from it.

Material Input: The material is generally a slurry that includes solid particles and liquid residing within the mixture. This material is fed to the belt press.

Transport: The system transports material evenly in a porous belt. In addition, this belt, typically made from a strong fabric or synthetic material, allows fluids to drain while retaining solids.

Roll Pressure: The system rolls the material (known as roll pressure) through a series of rollers, each with increasing amounts. Additionally, between these rollers, the belt moves, pressing the material against one aspect and thereby forcing any liquid out.

Dewatering: As the material travels throughout the press, the system expresses water into a tray. Meanwhile, the system allows the rest of the solid, which is now considerably drier, to keep creeping down.

Filter cake (solids): The system dehydrates the sludge and discharges it at the end of the press. And then it’s either for further processing or for disposal.

Belt filter technical sheet

| Sludge Kinds | Input Concentration % | Capacity m³/h | DS Capacity kg/h | Moisture of Cake % | PAM Consumption %(DP/DS) |

| Unconcentrated Aerobic Sludge | 0.5~1.5 | 15~30 | 150~300 | ~80 (+2) | 2~5 |

| Concentrated Aerobic Sludge | 2~4 | 6~12 | 200~300 | ~80 (+2) | 2~5 |

| Digested Sludge | 3~6 | 7~15 | 300~400 | <80 | 2~5 |

| Unconcentrated Primary Sludge | 0.8~2.0 | 18~35 | 300~400 | <80 | 2~5 |

| Concentrated Primary Sludge | 3~5 | 6~12 | 300~400 | <80 | 2~5 |

| Paper-making Activated Sludge | 0.5~2.5 | 15~35 | 200~400 | <78 | 3~7 |

| Printing and Dyeing Mixed Sludge | 1~3 | 10~25 | 180~350 | 75~78 | 3~10 |

| Model | Belt Width | Sludge Concentration | Outlet Concentration | Capacity | Power |

| DNT-1000 | 1000mm | 2-4% | 15-25% | 6-12 | 1.49kW |

| DNT-1500 | 1500mm | 2-4% | 15-25% | 12-15 | 2.05kW |

| DNT-2000 | 2000mm | 2-4% | 15-25% | 15-25 | 2.6kW |

| DNT-2500 | 2500mm | 2-4% | 15-25% | 35-50 |

4.1kW |

Belt filter press applications

Municipal:

Industrial:

Food Processing Wastes, Pulp & Paper Wastes, Chemical Sludges, Pharmaceutical Wastes, Industrial Wastes Processing Sludges, Petrochemical Wastes

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China