Static Screen Wastewater Description

The static screen has a built-in screen. The screen consists of a horizontal bar with a special profile and is made of Aisi 304 or 316 quality stainless steel.

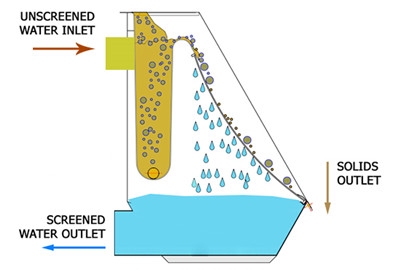

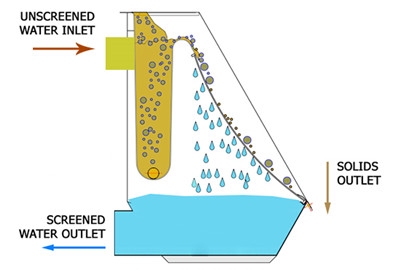

The water is distributed in the upper part of the filter screen, and its inclination on the horizontal surface gradually decreases from top to bottom. The effect of solid matter separation and dripping is obtained sequentially.

Static Screen Wastewater Works

Static Screen head box reduces turbulence of wastewater or processed slurry and delivers flow to the wire. A swing baffle distributes flow across the width of the screen surface and the liquid is then separated out of the slurry as it passes across the upper part of the screen panel. Most of the solids are captured on the curved face of the screen while the liquid is drained to the bottom part via the back of the screen. This screen provides excellent liquid/solid separation at a low capital cost and low maintenance.

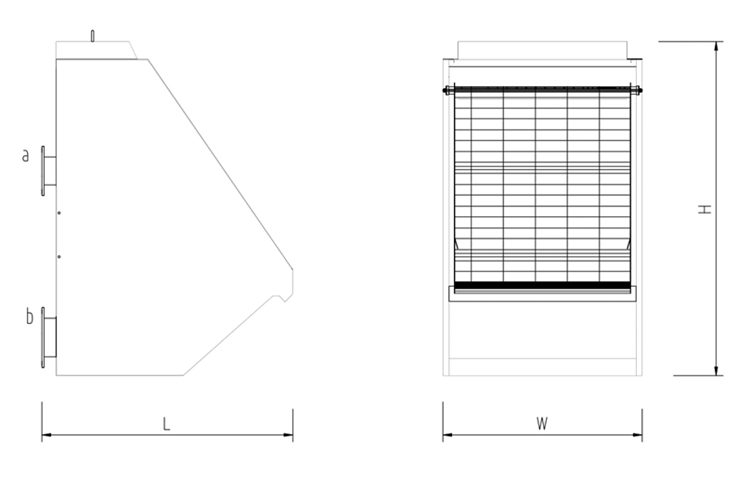

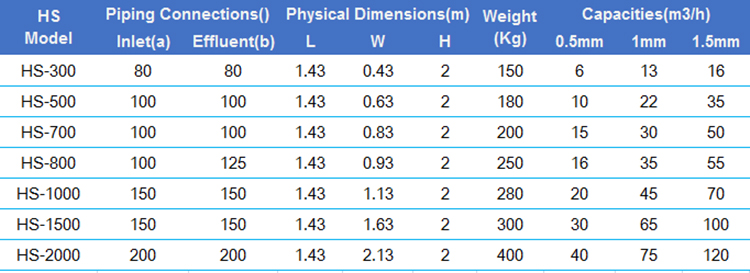

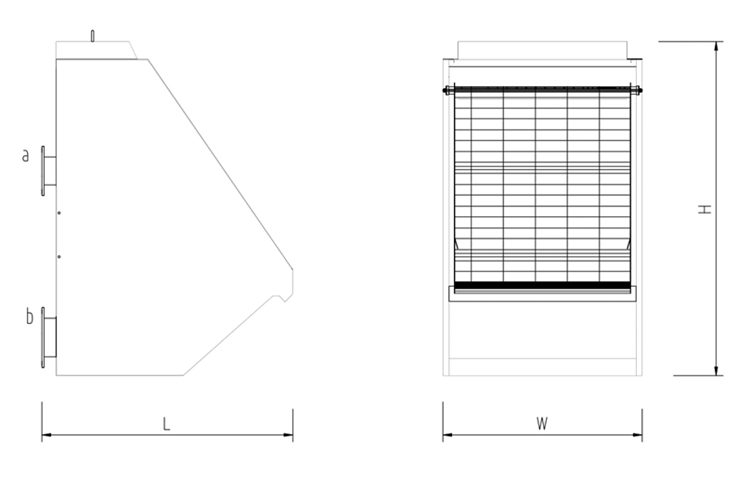

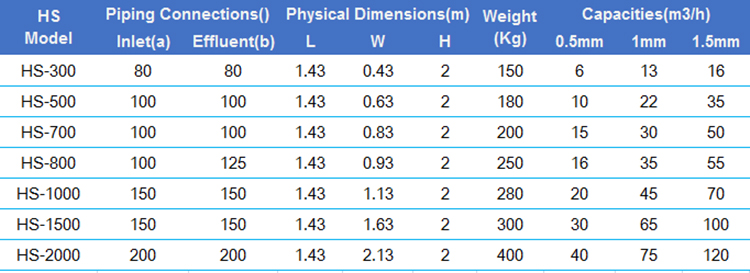

Static Screen Wastewater Model

Static Screen Wastewater Advantage

What are the advantages of static screens in wastewater treatment? One of the first benefits is that they’re cost-effective. They do not require electricity, and the purchase and installation costs are not out of reach, especially when you consider that they help make the rest of the wastewater treatment process a little easier to manage. Static screens also require very little maintenance, so you won’t need to spend a lot of time training or hiring additional workers to keep the screens maintained.

They clean themselves with water spray or bar rakes that clear the screen’s bars as the system moves around with the water’s current. Some are also self-reversing to clear any jams that may occur after a storm where large branches enter systems that combine wastewater and stormwater runoff.

Static screens do their job effectively. The mesh screens capture a lot. They can remove small particles of solidified grease, corn skins that are harder for a body to digest, or bone particles from animals that get into a sewer and end up in wastewater. With these items removed before the remaining wastewater treatment measures take place, it eases wear and tear on equipment and gets the treatment process started faster.

With a static screen, they don’t need ideal conditions in order to work correctly. It doesn’t matter if flow rates increase or decrease or if temperatures are colder or hotter than usual. Static screens will work effectively in any condition.

Because static screens come in a variety of sizes and formats, it’s easy to fit one into your existing system. Some require very little headroom. When you’re shopping for the best static screen, finding a variety of sizes ends up helping out if you have little space.

Static Screen Wastewater Application

-

Wastewater Treatment: Ideal for removing suspended solids from industrial wastewater.

-

Food and Beverage Processing: Ensures purity and safety in the production of beverages and food products.

-

Pulp and Paper Industry: Efficiently separates fibers and particles in the pulp and paper manufacturing process.

-

Chemical Processing: Provides reliable filtration in various chemical processing applications.