Polymer preparation units are automated systems for the preparation of liquid or powdered polymers, designed for the fully automated dosing of polymer solutions.

The Polymer Dosing System can be used to batch flocculation aids for the preparation of ready-to-use polymer solutions. The design is optimized to ensure that the polymer maturation process is completed with minimal footprint.

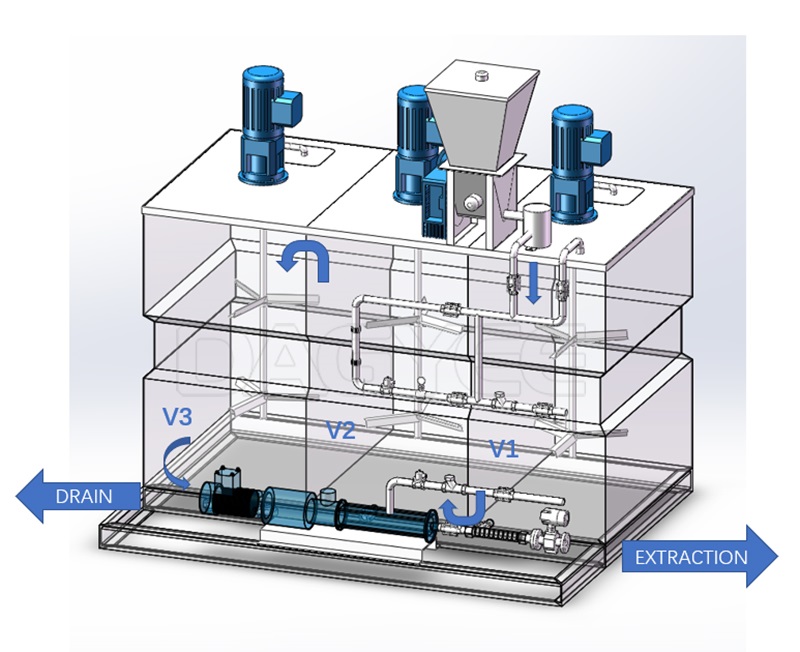

The baffles allow the polymer formulation to circulate through a series of compartments. This ensures optimal reaction times and continuous concentration levels in each compartment, thus avoiding any preferential routes between the preparation compartment and the final dosing solution compartment.

Automation is achieved by a control panel connected to an ultrasonic level detector located above the dosing solution compartment. Once the solution in the dosing chamber reaches “low level”, the detector activates the opening of the inlet motorized valve and the activation of the dry feeder. The water meter continuously controls the flow rate. Once a “high level” is reached, the process cycle stops.

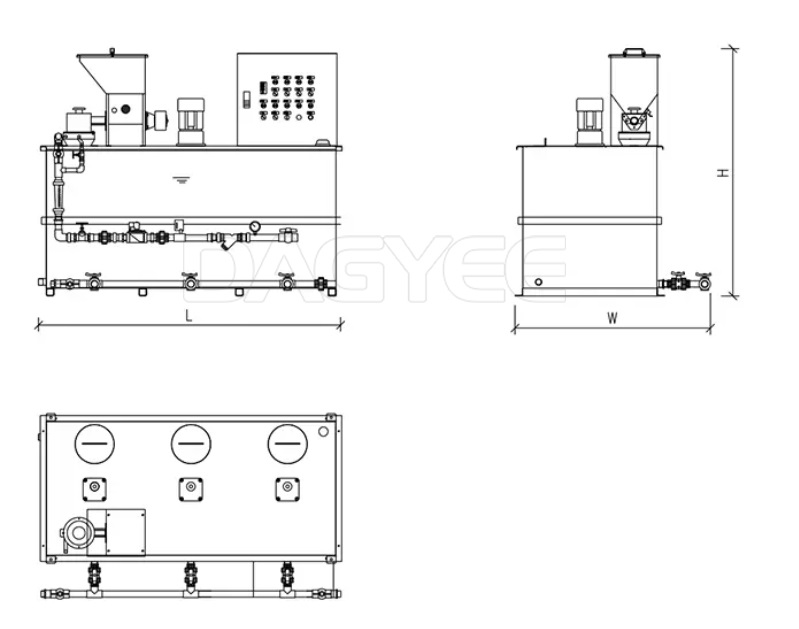

Polymer preparation unit model

| Model | Capacity L/H | Volume L | Timing H | Dimensions MM | Weight KG | Power KW |

|---|---|---|---|---|---|---|

| DT300 | 300 | 450 | 0.6-1 | 1500*1000*500 | 300 | 1.8 |

| DT500 | 500 | 750 | 0.6-1 | 1500*1000*650 | 420 | 1.8 |

| DT1000 | 1000 | 1500 | 0.6-1 | 2000*1000*900 | 500 | 2.8 |

| DT1500 | 1500 | 2250 | 0.6-1 | 2000*1200*900 | 620 | 3 |

| DT2000 | 2000 | 3000 | 0.6-1 | 2500*1200*1000 | 800 | 3.9 |

| DT3000 | 3000 | 4500 | 0.6-1 | 3000*1500*1000 | 950 | 5.3 |

| DT5000 | 5000 | 7500 | 0.6-1 | 5000*1500*1000 | 1250 | 7 |

| DT10000 | 10000 | 15000 | 0.6-1 | 4800*1800*2000 | 3600 | 7 |

Lower Maintenance & Downtime: No moving parts in the mixing process along with the durable DFXa peristaltic or gamma/ XL diaphragm pump means fewer breakdowns and less frequent repairs.

More Efficient Polymer Usage: Venturi mixing & static mixer ensure optimal polymer activation, reducing chemical waste. Consistent dosing improves treatment efficiency, lowering operating costs.

Ease of Operation & Automation: Multiple control modes (Manual, Analog, Contact, Auxiliary) allow simple or advanced operation. 4-20 mA and alarm outputs enable remote monitoring and integration with SCADA/PLC systems.

Consistent high-quality flocculant solution

The raw material dosing is linked to water flow to ensure that the final flocculant concentration remains constant.

Prevents unnecessary over-dosing

Dosing is linked to incoming waterflow.

Optimal design

Separate sections for make-up, maturation and solution storage.

Clot prevention

The end of the dosing auger is heated to prevent flocculant granulate from absorbing moisture from the air.

Convenient

The make-up parameters can be set in the control panel.

Polymer preparation unit application

The use of polymers or floculants considerably improves the separation process between the solid/liquid phases for applications in:

Contact us:

Company: Wuxi Dajiang Environmental Technology Co., Ltd. DAGYEE

Phone/WhatsApp:+8613961861780

Email: info@dagyee.com

Website: www.dagyee.com

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China