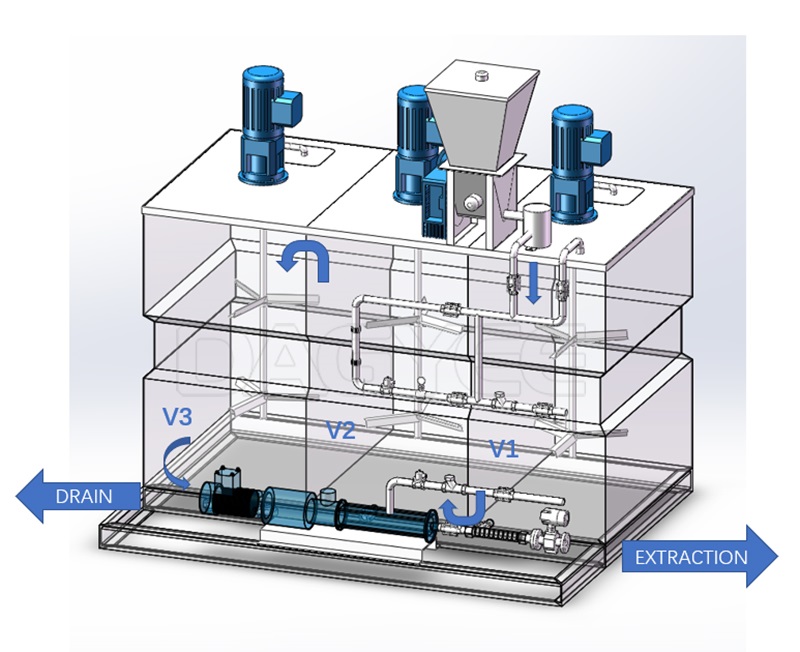

Polymer Preparation System is a compact automated metering unit for liquid or powder polymer preparation and dosing. Designed specifically for uniformity of flocculant concentration, the design is optimized to ensure that the polymer completes the maturation process with minimal footprint. Also often referred to as powder dosing systems, Polymer Dosing Systems, PAM PAC dosing systems.

The pre-assembled polymer unit features two cylindrical chambers for dosing, maturation and storage of liquid or powdered polymer solutions, which are hydraulically coupled via overflow channels. In addition, three motorized stirrers provide agitation to ensure consistent performance.

The baffles allow the polymer formulation to circulate through a series of compartments. This ensures optimal reaction times and continuous concentration levels in each compartment, thus avoiding any preferential routes between the preparation compartment and the final dosing solution compartment.

Automation is achieved by a control panel connected to an ultrasonic level detector located above the dosing solution compartment. Once the solution in the dosing chamber reaches “low level”, the detector activates the opening of the inlet motorized valve and the activation of the dry feeder. The water meter continuously controls the flow rate. Once a “high level” is reached, the process cycle stops.

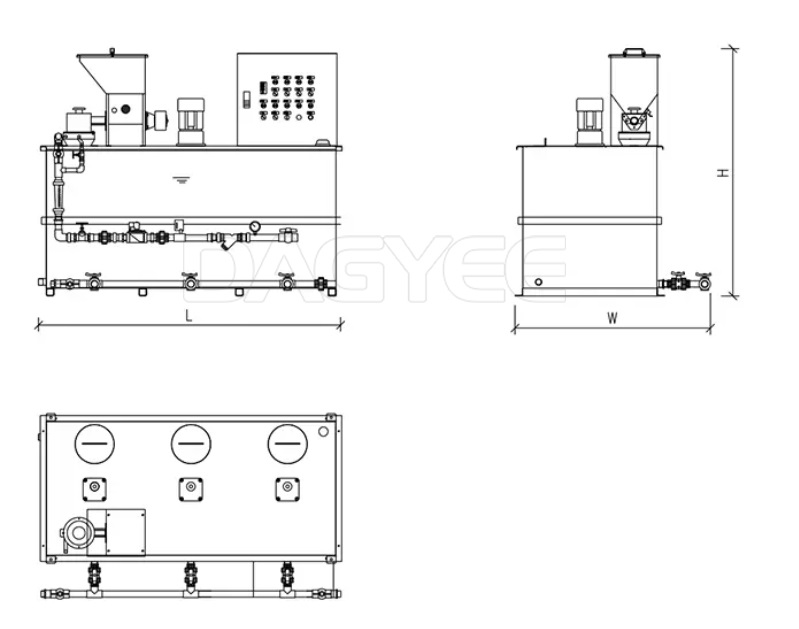

Polymer preparation unit model

| Model | Capacity L/H | Volume L | Timing H | Dimensions MM | Weight KG | Power KW |

|---|---|---|---|---|---|---|

| DT300 | 300 | 450 | 0.6-1 | 1500*1000*500 | 300 | 1.8 |

| DT500 | 500 | 750 | 0.6-1 | 1500*1000*650 | 420 | 1.8 |

| DT1000 | 1000 | 1500 | 0.6-1 | 2000*1000*900 | 500 | 2.8 |

| DT1500 | 1500 | 2250 | 0.6-1 | 2000*1200*900 | 620 | 3 |

| DT2000 | 2000 | 3000 | 0.6-1 | 2500*1200*1000 | 800 | 3.9 |

| DT3000 | 3000 | 4500 | 0.6-1 | 3000*1500*1000 | 950 | 5.3 |

| DT5000 | 5000 | 7500 | 0.6-1 | 5000*1500*1000 | 1250 | 7 |

| DT10000 | 10000 | 15000 | 0.6-1 | 4800*1800*2000 | 3600 | 7 |

Avoid the need for manual operations – Prevent dosing errors, operation stops.

Standardization of the obtained polymer – Concentration, maturation time, homogeneity.

High efficiency mixers – Provide a low flow mixing for a homogeneous flocculant polymerisation without mechanical deterioration.

Optimised process – Visual access to the process and alarms, fieldbus distributed control (optional) provides informative and easy to access equipment and status application updates, controlled costs. Intelligent system that feeds the process when needed, regulated by an ultrasonic level switch.

Reliability and Robustness in Any Environment.

Fully automated operation — saves labor costs and prevents dosing errors, operation stops

Standardization of the resulting polymer — concentration, maturation time, homogeneity

High efficiency mixer — Provides low flow mixing for homogeneous flocculant polymerization without mechanical degradation

Optimized process — visual access to process and alarms, can feed the process when needed, regulated by ultrasonic level switches

Compact design — easy to transport and relocate

Safe and reliable — operation with airlift and overflow protection

Polymer preparation unit application

Municipal Sewage

Slaughter House

Metallurgical Industry Wastewater

Spraying Sewage

Printing & Dyeing Sewage

Metal-Processing Sewage

Mining Stone Wastewater

Electronic Sewage

Contact us:

Company: Wuxi Dajiang Environmental Technology Co., Ltd. DAGYEE

Phone/WhatsApp:+8613961861780

Email: info@dagyee.com

Website: www.dagyee.com

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China