Compact Units Pretreatment Plants For Wastewater Treatment Description

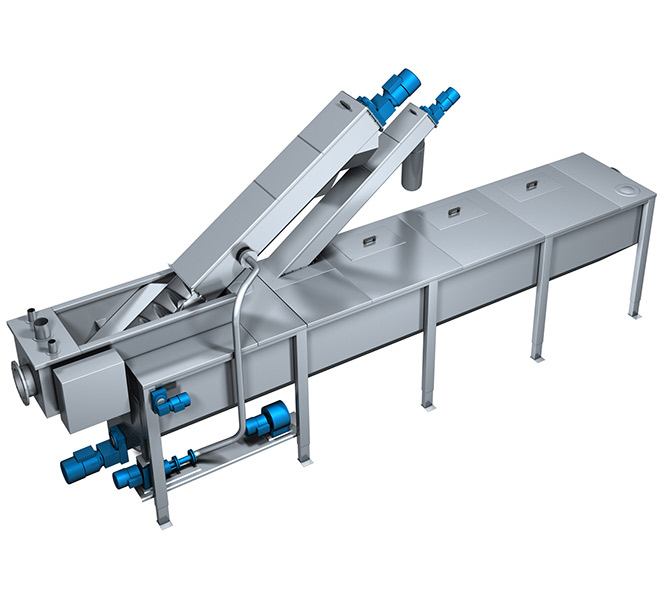

The Combined Pre-Treatment Plant is a complete, above-ground headworks requiring minimal space and civil works. Debris, grit/sand and grease can all be removed in this one compact system. For small plants, this system can function as an entire pre-treatment headworks or it can be a simple, economical way to increase pre-treatment capacity.

With the addition of aeration and DAGYEE’s proprietary grease removal system, this unit can become a Septage, Sludge and FOG processing station. Depending on preference or application, a variety of screen types can be incorporated into the compact plant. With over 10 years of experience and 500 installations worldwide, DAGYEE’s application and technical knowledge insures proper sizing and component selection for each specific application.

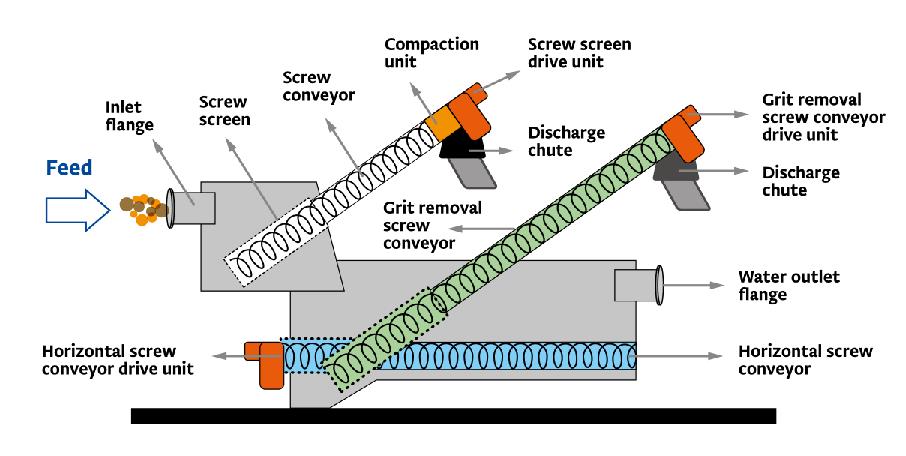

Combined Screening Component

Dependable, complete and compact unit Performing the following process steps:

Combined Screening Working Principle

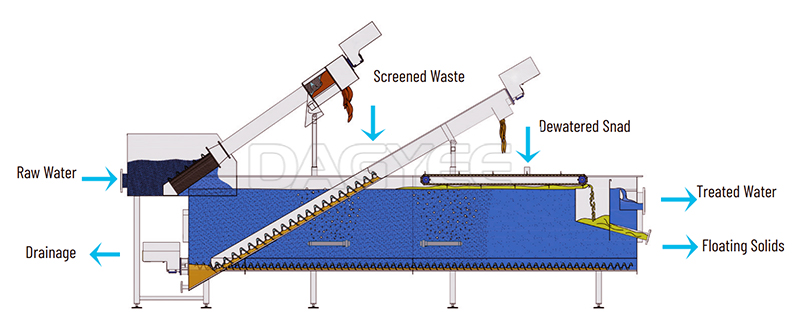

This compact pretreatment unit provides mechanical pretreatment on municipal or industrial wastewater treatment plants. All the steps of conventional pretreatment are combined in one sole equipment without any civil works constraints: screening, degritting and degreasing.

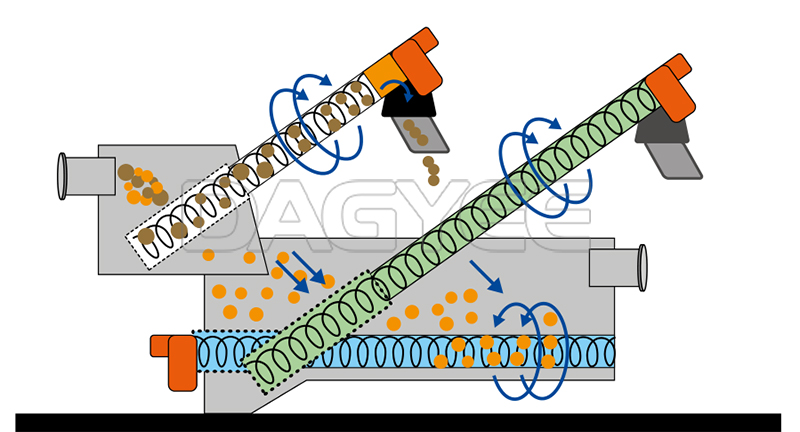

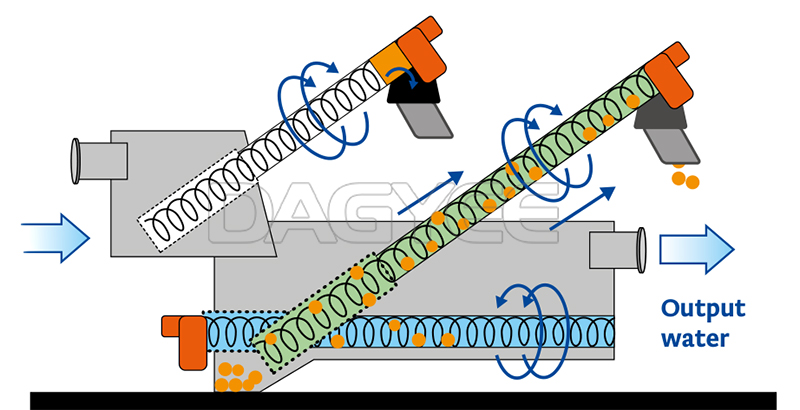

STEP 1 : fine screening – separation liquid/solidsUnité Prétraitement Compacte

ETAPE 2 : sand settling tank

STEP 3 : collection of the sand from the settling tank bottomUnité Prétraitement Compacte

ETAPE 4 : sand evacuation

The wastewater firstly enters the tank where a screw screen is placed.

Big size solid materials are filtrated by the screw screen and a screw conveyor moves the solid materials captured up to the discharge point. At the end of the conveyor, they are pressed by the compaction unit before discharge.

The water which has still solid materials in smaller sizes flows through the sedimentation tank. The particles are settled by time and a horizontal screwconveyor transports them to the collection hopper.

Finally, they are conveyed by the grit removal screw conveyor to the discharge point.

Combined Screening Parameter

| Power Specifications | ||||||

| Model | Capacity (m3/h) | Tank Length(mm) | Tank Width(mm) | Inlet Flange DN | Outlet Flange DN | Max.Wash Water(L/S) |

| DSP-30 | 30 | 4200 | 1200 | DN200 | DN200 | 0.5 |

| DSP-50 | 50 | 5800 | 1200 | DN200 | DN200 | 0.5 |

| DSP-100 | 100 | 7000 | 1200 | DN250 | DN250 | 1 |

| DSP-150 | 150 | 7000 | 1200 | DN250 | DN250 | 1 |

| DSP-200 | 200 | 8000 | 1500 | DN300 | DN300 | 1 |

| DSP-250 | 250 | 8500 | 1500 | DN350 | DN350 | 1 |

| DSP-350 | 350 | 10000 | 1500 | DN400 | DN400 | 1 |

| DSP-400 | 400 | 12000 | 1800 | DN500 | DN500 | 1 |

| DSP-500 | 500 | 15000 | 2000 | DN500 | DN500 | 1 |

| Power Specifications | ||||

| Model | Screw Screen Power(kw) | Screw Conveyor Power(kw) |

Grit Removal

Power(kw)

|

Grease Removal

Power(kw)

|

| DSP-30 | 0.55 | 0.25 | 0.37 | 0.18 |

| DSP-50 | 0.55 | 0.35 | 0.37 | 0.18 |

| DSP-100 | 0.75 | 0.37 | 0.55 | 0.18 |

| DSP-150 | 0.75 | 0.37 | 0.55 | 0.18 |

| DSP-200 | 0.75 | 0.55 | 0.75 | 0.18 |

| DSP-250 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-350 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-400 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-500 | 1.1 | 0.55 | 1..1 | 0.18 |

Combined Screening Features

This compact pretreatment unit provides mechanical pretreatment on municipal or industrial wastewater treatment plants. All the steps of conventional pretreatment are combined in one sole equipment without any civil works constraints: screening, degritting and degreasing.

STEP 1 : fine screening – separation liquid/solidsUnité Prétraitement Compacte

ETAPE 2 : sand settling tank

STEP 3 : collection of the sand from the settling tank bottomUnité Prétraitement Compacte

ETAPE 4 : sand evacuation

Combined Screening Advantages

Combined Screening Applications

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China