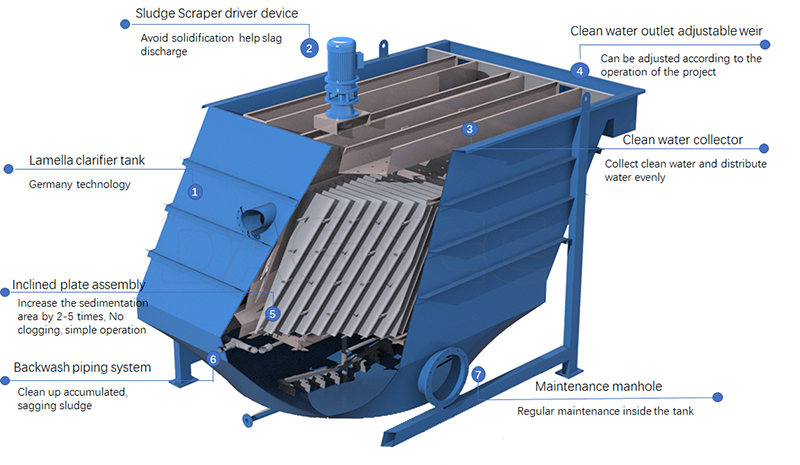

Inclined Plate Clarifier Description

Inclined plate clarifier also called inclined plate sediment tank. It is good at high efficient combined type settling tank; set many dense inclined tube packing in sediment area, to make the suspended impurity in water sediment, water rise flow along inclined tube, the separated sludge down to the tank bottom along the inclined tube by gravity, then discharge it in concentration. Such tank can improve sediment efficiency 60~70%, it can improve treatment capacity 3~5 times in the same area. It can design different flow rate inclined plate sediment device according to raw waste water test report, it need dose flocculant usually.

Available options

Inclined Plate Clarifier Model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

DLC

Model

Capacities

(m3/h)

Piping Connections()

Physical Dimensions(m)

Inlet(a)

Effluent(b)

Sludge(c)

Backwash(d)

L

W

H

DLC-

5

80

80

50

50

2.55

1.6

2.9

DLC-

10

100

100

50

50

3.35

1.82

3

DLC-

15

100

100

50

50

3.35

2.02

3

DLC-

20

100

100

50

50

3.35

2.02

3

DLC-

30

150

150

50

50

4.2

2.22

3

DLC-

40

150

150

50

50

4

2.8

3

DLC-

50

200

200

50

50

4.65

2.82

3

DLC-

60

200

200

50

50

4.7

3

3

DLC-

70

250

200

50

50

6.4

2.6

3

DLC-

80

250

200

50

50

6.8

2.82

3

DLC-

100

250

250

50

50

7.05

3.02

3

Inclined Plate Clarifier Advantages

Lamella Separator Applications

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China