Compact Units Pretreatment Plants For Wastewater Treatment Description

Mechanical pre-treatment is very important for protection of subsequent processes in a

wastewater treatment plant in order to operate the entire plant reliably. Wastewater has to be

pre-treated before being transferred to the subsequent stages of the wastewater treatment plant so that the overloading of the downstream treatment system is avoided.

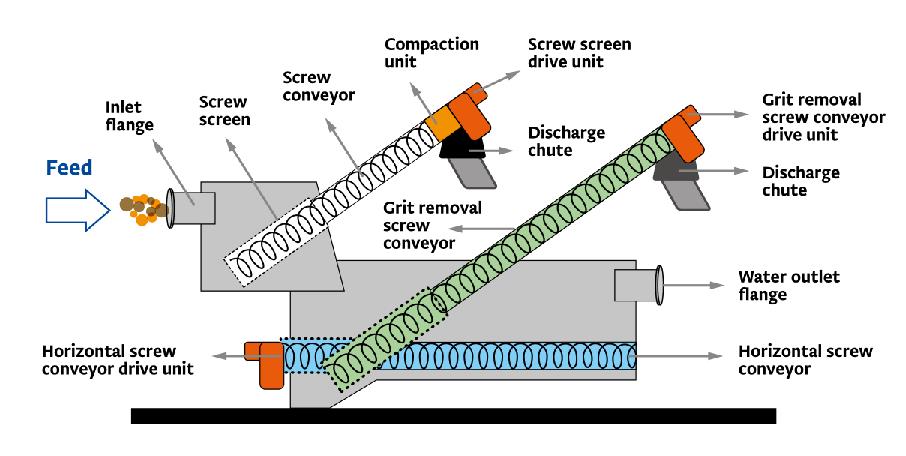

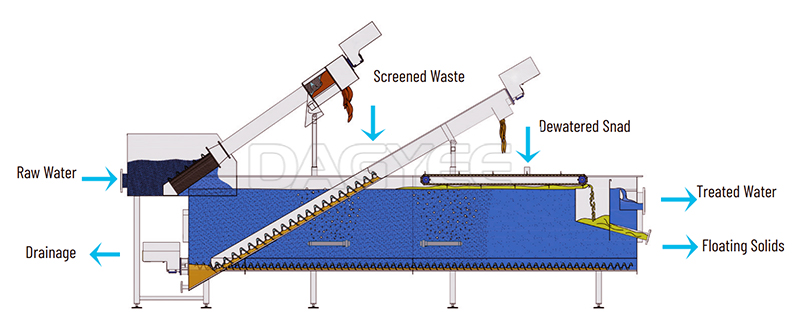

Wastes, passing through the screw screen, are screened and the bigger solid particles are

removed. Then, effluents pass in the tank (hopper) section, where finer solids particles are

allowed to settle down and are removed by a low rotating shaftless screw system. As an option, the unit can be designed with an oil/grease removing system.

Options of alternative voltage and frequency, degree of motor protection, control panel, drive

guard, screen type, overflow chutes, fixed internal pipe are available upon request.

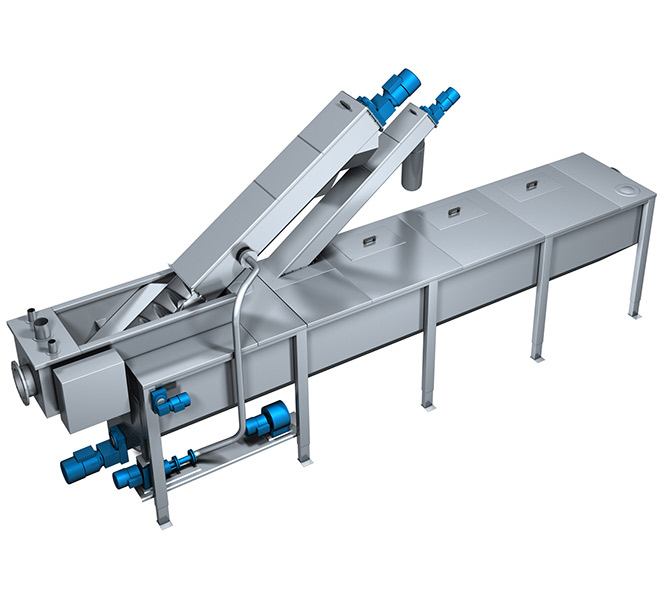

DAGYEE Uluslararası Combined Wastewater Pre-treatment Units have screw screen, screenings treatment, grit traps (for solids- stones, grit, sand, etc. removal) and as optional grease traps (for fat, oil and grease removal).

Combined Screening Component

Dependable, complete and compact unit Performing the following process steps:

fine screening

Screenings dewatering

Grit separation

Grit dewatering

Grease separation and removal (optional)

Combined Screening Working Principle

It is a comprehensive combined unit designed for the preliminary treatment of wastewater before it enters a wastewater treatment plant. This unit efficiently performs three key operations: screening, grit removal, and grease removal.

In the screening process, wastewater passes through a screen that eliminates larger particles. This screen, which can be a spiral screen (TSS or SSS type) or a rotary drum screen (TR type), also washes and compacts the screenings before their discharge. The efficiency of this process is influenced by the screen’s perforation and its capture rate. Additionally, the screen tank can include a by-pass tank with a manual screen, and the screen basket or drum can be made from either perforated plate or wedge wire.

Following the screening section, the wastewater proceeds to the settling tank for grit sedimentation. A specially designed baffle in this tank ensures a laminar flow and helps to equalize temperature differences, thereby enhancing the sedimentation process. The settled grit accumulates in a pit and is then removed by an inclined screw conveyor, known as a grit classifier, which can optionally include a washing system.

For the removal of suspended particles such as oil, grease, and other substances, the unit employs a system of paddles made from stainless steel wire. The settling tank is equipped with an air blower to further facilitate the separation of organic matter and the settlement of grit. Larger units may be fitted with two blowers for increased efficiency.

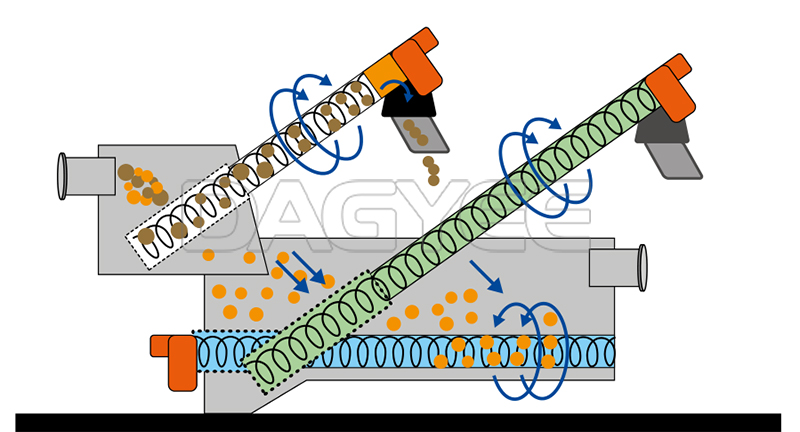

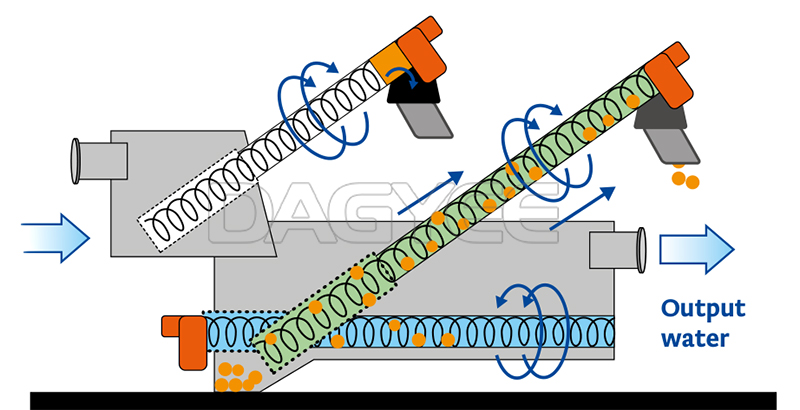

The wastewater firstly enters the tank where a screw screen is placed.

Big size solid materials are filtrated by the screw screen and a screw conveyor moves the solid materials captured up to the discharge point. At the end of the conveyor, they are pressed by the compaction unit before discharge.

The water which has still solid materials in smaller sizes flows through the sedimentation tank. The particles are settled by time and a horizontal screwconveyor transports them to the collection hopper.

Finally, they are conveyed by the grit removal screw conveyor to the discharge point.

Combined Screening Parameter

| Power Specifications | ||||||

| Model | Capacity (m3/h) | Tank Length(mm) | Tank Width(mm) | Inlet Flange DN | Outlet Flange DN | Max.Wash Water(L/S) |

| DSP-30 | 30 | 4200 | 1200 | DN200 | DN200 | 0.5 |

| DSP-50 | 50 | 5800 | 1200 | DN200 | DN200 | 0.5 |

| DSP-100 | 100 | 7000 | 1200 | DN250 | DN250 | 1 |

| DSP-150 | 150 | 7000 | 1200 | DN250 | DN250 | 1 |

| DSP-200 | 200 | 8000 | 1500 | DN300 | DN300 | 1 |

| DSP-250 | 250 | 8500 | 1500 | DN350 | DN350 | 1 |

| DSP-350 | 350 | 10000 | 1500 | DN400 | DN400 | 1 |

| DSP-400 | 400 | 12000 | 1800 | DN500 | DN500 | 1 |

| DSP-500 | 500 | 15000 | 2000 | DN500 | DN500 | 1 |

| Power Specifications | ||||

| Model | Screw Screen Power(kw) | Screw Conveyor Power(kw) |

Grit Removal

Power(kw)

|

Grease Removal

Power(kw)

|

| DSP-30 | 0.55 | 0.25 | 0.37 | 0.18 |

| DSP-50 | 0.55 | 0.35 | 0.37 | 0.18 |

| DSP-100 | 0.75 | 0.37 | 0.55 | 0.18 |

| DSP-150 | 0.75 | 0.37 | 0.55 | 0.18 |

| DSP-200 | 0.75 | 0.55 | 0.75 | 0.18 |

| DSP-250 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-350 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-400 | 1.1 | 0.55 | 0.75 | 0.18 |

| DSP-500 | 1.1 | 0.55 | 1..1 | 0.18 |

Combined Screening Features

Combined Screening Advantages

Odor-free • No clogging

Low maintenance and operation costs

Low room needed • No construction works needed

Easy to install and operate

Very low residual organic content in the washed out solid

Volume reduction (up to 40%) of the washed out solid

Sand removal: >=90% of particles up to 200 μ

Combined Screening Applications

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China