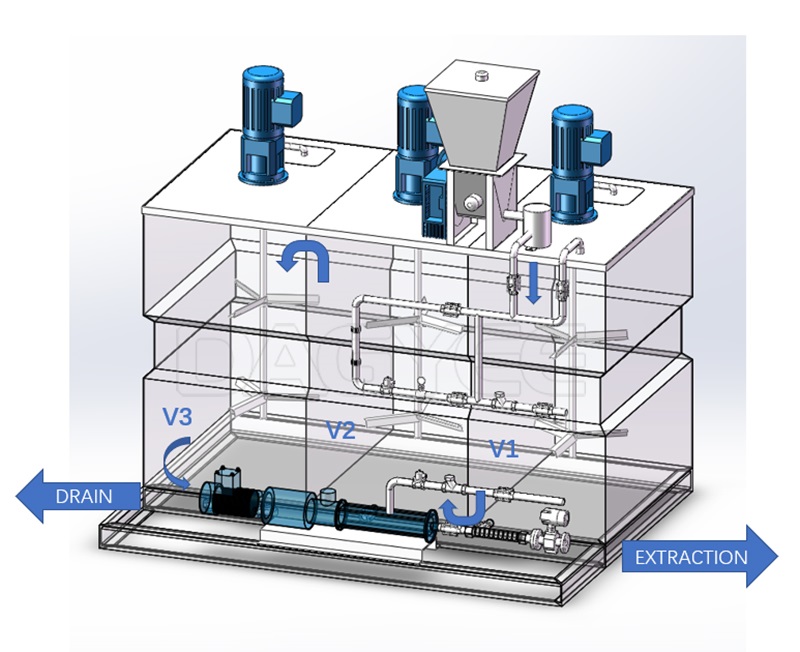

The DAGYEE system is automated by the control panel connected to the ultrasonic level detector located above the dosing solution compartment. As soon as the solution in the dosing compartment reaches “low level”, the detector activates the opening of the water feed electrovalve and the start-up of the dry feeder. The water meter controls the flow continuously. As soon as the “high level” is reached, the process cycle stops, although the mixers (one, two or three according the model) continue to operate.

The polymer preparation system is an intelligent, fully automatic, continuous and integrated dry powder dissolving and dosing device. The device consists of a water supply system, a dry powder dosing system, a dissolving and curing system, and an automatic control system.

This device is a fully automatic continuous configuration and dosing system for powdered medicaments. The dry powder agent enters the premixer from the screw propeller at the lower part of the hopper for premixing with clean water, the wetted material enters the preparation tank for dilution and mixing, and is prepared according to the concentration required by the user.

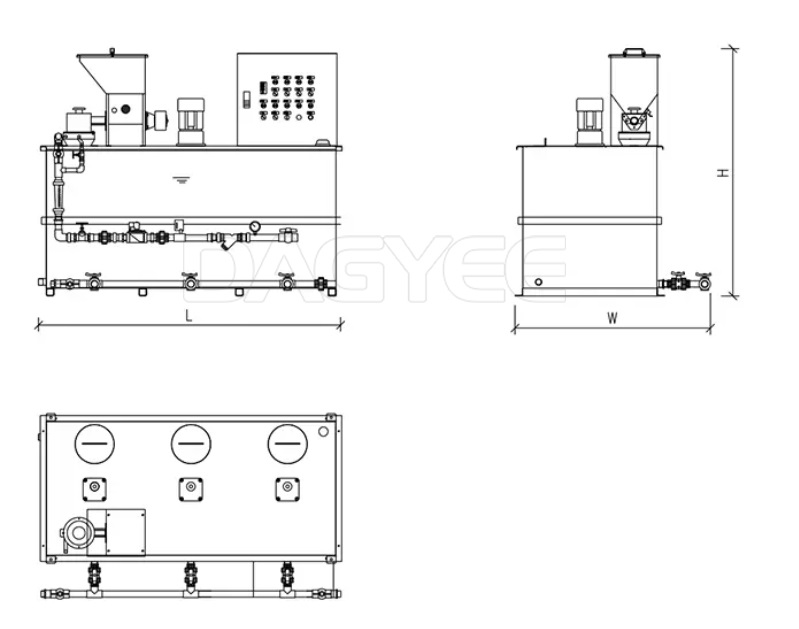

Polymer preparation unit model

| Model | Capacity L/H | Volume L | Timing H | Dimensions MM | Weight KG | Power KW |

|---|---|---|---|---|---|---|

| DT300 | 300 | 450 | 0.6-1 | 1500*1000*500 | 300 | 1.8 |

| DT500 | 500 | 750 | 0.6-1 | 1500*1000*650 | 420 | 1.8 |

| DT1000 | 1000 | 1500 | 0.6-1 | 2000*1000*900 | 500 | 2.8 |

| DT1500 | 1500 | 2250 | 0.6-1 | 2000*1200*900 | 620 | 3 |

| DT2000 | 2000 | 3000 | 0.6-1 | 2500*1200*1000 | 800 | 3.9 |

| DT3000 | 3000 | 4500 | 0.6-1 | 3000*1500*1000 | 950 | 5.3 |

| DT5000 | 5000 | 7500 | 0.6-1 | 5000*1500*1000 | 1250 | 7 |

| DT10000 | 10000 | 15000 | 0.6-1 | 4800*1800*2000 | 3600 | 7 |

Considerable savings in terms of polymer usage and running costs

Precision in the preparation and batching stages, optimising the processes

Mixing properties adapted to specific needs of the process

Space saving and system centralisation

Well controlled hydraulic retention and contact times

An automatic water supply system comprising a shut-off valve, filter, safety pressure switch, pressure gauge, pressure reducer valve, solenoid valve, water meter with pulses, control valve, flow meter (with flow switch for minimum level flow rate) and special dispensing nozzle (for units that work with powder polymers).

Tanks made entirely in PPH, with inspection covers and emptying valves for each chamber.

Customized mixers, optimized to ensure a homogeneous mixture, are made of stainless steel.

Batching screw made entirely of stainless steel, with batching adjustment managed using a precise speed regulator.

Polymer preparation unit application

Using polymers and flocculants considerably facilitates the processes of removing particles and solids suspended in liquid in the fo lowing applications:

• Treating potable and industrial processing water

• Purifying waste water

• Treating sludge, in order to improve the performance of centrifuges and filter presses

• Processes for the paper, chemical, petrochemical, mineral processing, canning industries

Contact us:

Company: Wuxi Dajiang Environmental Technology Co., Ltd. DAGYEE

Phone/WhatsApp:+8613961861780

Email: info@dagyee.com

Website: www.dagyee.com

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China