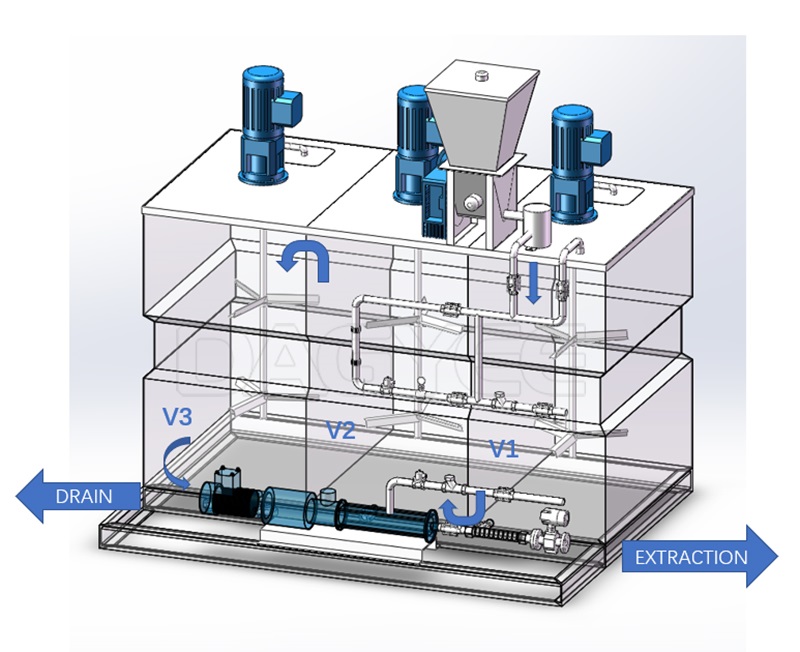

It is a pre-engineered polymer mixing system made for the water and wastewater markets. Designed as an in-line unit, it can be customized to meet most liquid polymer applications utilizing tubing or diaphragm pump technologies depending on the application requirement or customer preference. The unique mixing chamber allows for complete makedown of the neat or diluted polymer to guarantee a problem-free injection.

The sera PolyLine Flow is a 3-Chamber-unit.

Fully automatic preparation of organic flocculent aid

(pulverized and/or liquid)

Process logic control (PLC)

Selectable concentration of prepared solution

Feeding device

Dry material feeder with thermal protection zone

Pump for liquid polymer (option)

Dissolving water unit

Electric agitators

Performance graduation that meets the requirements

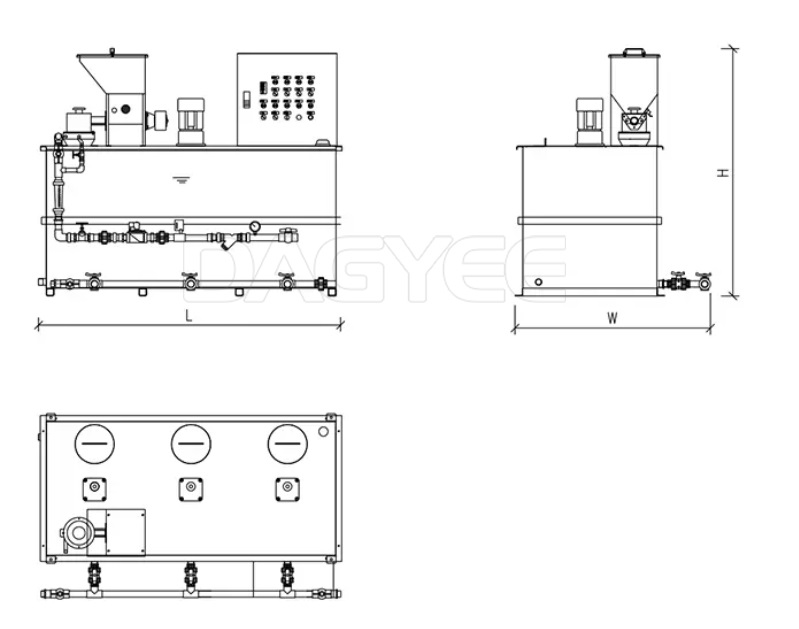

Polymer preparation unit model

| Model | Capacity L/H | Volume L | Timing H | Dimensions MM | Weight KG | Power KW |

|---|---|---|---|---|---|---|

| DT300 | 300 | 450 | 0.6-1 | 1500*1000*500 | 300 | 1.8 |

| DT500 | 500 | 750 | 0.6-1 | 1500*1000*650 | 420 | 1.8 |

| DT1000 | 1000 | 1500 | 0.6-1 | 2000*1000*900 | 500 | 2.8 |

| DT1500 | 1500 | 2250 | 0.6-1 | 2000*1200*900 | 620 | 3 |

| DT2000 | 2000 | 3000 | 0.6-1 | 2500*1200*1000 | 800 | 3.9 |

| DT3000 | 3000 | 4500 | 0.6-1 | 3000*1500*1000 | 950 | 5.3 |

| DT5000 | 5000 | 7500 | 0.6-1 | 5000*1500*1000 | 1250 | 7 |

| DT10000 | 10000 | 15000 | 0.6-1 | 4800*1800*2000 | 3600 | 7 |

1. Easy installation, high degree of automation and simple operation;

2. Stable performance, long service life, easy maintenance, low operation and total investment;

3. The dosage of pharmaceuticals can be accurately adjusted to avoid unnecessary waste of pharmaceuticals;

4. The dosing barrel has strong resistance to chemical corrosion and good acid and alkali resistance;

5. Beautiful appearance, small footprint and compact structure.

Each chamber is fitted with a tightly-secured inspection cover and emptying valve

User-guided input of solvent concentration

Minimal product carry over

Programmable logic controller (PLC)

Control cabinet for automatic control of the entire system

Optional automatic control panel version with proportional polymer dosage

Version with terminal box available on request

Polymer preparation unit application

Physical chemical treatment, sludge dewatering

Industrial applications: Food & Beverage, Textile, Slaughterhouses, Fish and Meat, Dairy, Recycling industry, Transshipment terminals for ore and coal, Chemical industry, Tank cleaning, Drinking water production, …

Contact us:

Company: Wuxi Dajiang Environmental Technology Co., Ltd. DAGYEE

Phone/WhatsApp:+8613961861780

Email: info@dagyee.com

Website: www.dagyee.com

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China