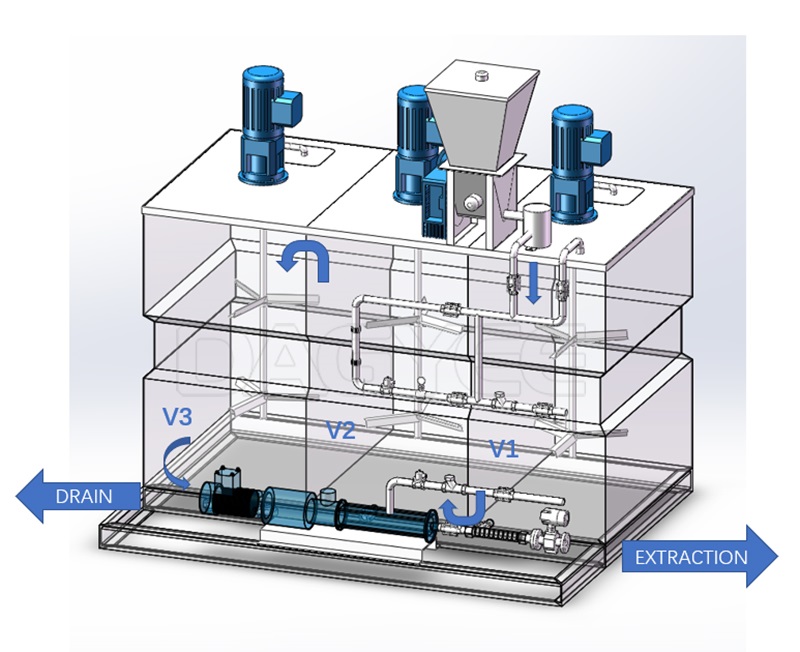

The DAGYEE system is automated by the control panel connected to the ultrasonic level detector located above the dosing solution compartment. As soon as the solution in the dosing compartment reaches “low level”, the detector activates the opening of the water feed electrovalve and the start-up of the dry feeder. The water meter controls the flow continuously. As soon as the “high level” is reached, the process cycle stops, although the mixers (one, two or three according the model) continue to operate.

Powder polymers are diluted in 3 chamber units. The first compartment is used for active mixing of the powder into the water flow. In the second chamber, the solution is matured by additional mixing. The third chamber acts as storage chamber. Powder polymer units are fitted with a powder storage hopper and dosing screw. The unit doses know amounts of powder into the incoming clean water flow, controlled by the water panel.

Manual and batch units require operator interactions, where fully automatic units start the solution preparation cycle automatically whenever the start level is reached in the storage chamber. The automatic unit can be used for continuously polymer injection into treatment processes.

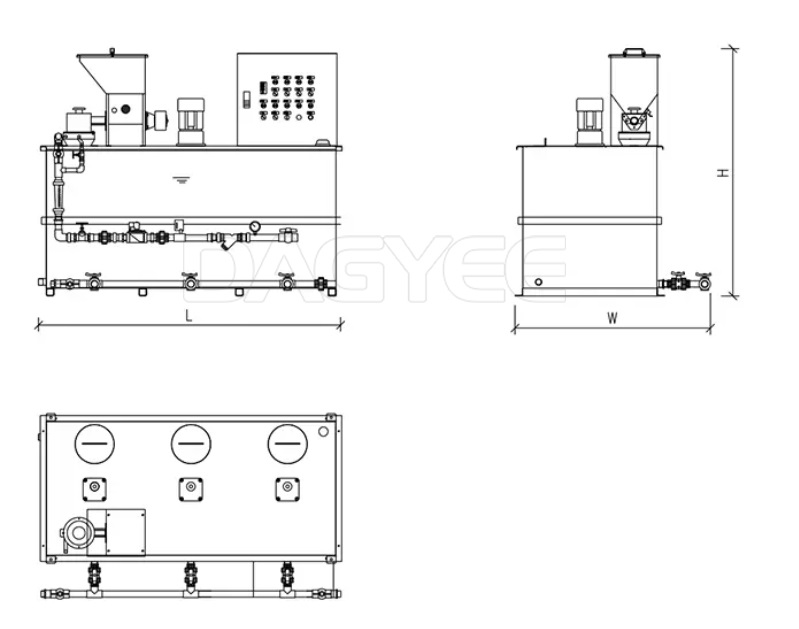

Polymer preparation unit model

| Model | Capacity L/H | Volume L | Timing H | Dimensions MM | Weight KG | Power KW |

|---|---|---|---|---|---|---|

| DT300 | 300 | 450 | 0.6-1 | 1500*1000*500 | 300 | 1.8 |

| DT500 | 500 | 750 | 0.6-1 | 1500*1000*650 | 420 | 1.8 |

| DT1000 | 1000 | 1500 | 0.6-1 | 2000*1000*900 | 500 | 2.8 |

| DT1500 | 1500 | 2250 | 0.6-1 | 2000*1200*900 | 620 | 3 |

| DT2000 | 2000 | 3000 | 0.6-1 | 2500*1200*1000 | 800 | 3.9 |

| DT3000 | 3000 | 4500 | 0.6-1 | 3000*1500*1000 | 950 | 5.3 |

| DT5000 | 5000 | 7500 | 0.6-1 | 5000*1500*1000 | 1250 | 7 |

| DT10000 | 10000 | 15000 | 0.6-1 | 4800*1800*2000 | 3600 | 7 |

■ Easy to operate, labor saving

Precast mixing tank, homogeneous slaking tank and solution storage tank are in one equipment, easy to learn and easy to operate, saving labor.

■ Polymer concentration is adjustable

Water and polymer can get into the tank at the same time, as the flowing rate of the feeding pump can be controlled, so any concentration (within a certain range) can be prepared according to the actual requirements.

■ Well designed machine frame

Precious conveying, delicate pre-soaking device and the constant temperature heating method can reduce agglomeration phenomenon caused by improper operation and prevent the line from clogging, so as to ensure the stable concentration.

Fully automated, continuous 24/7 operation with stable concentration output

Suitable for polymer powders and liquids, with separate feed lines

Applicable across sectors – wastewater, mining, oil & gas, chemical processing

No dedicated operator required – only ~30 min/day for refilling and inspection

Zero powder loss – 100% utilization of polymer without waste

Consistent, lump-free polymer solution

Post-Dilution capability – doubles capacity and enables effluent reuse

Fast return on investment due to savings in chemical, labor, and improved process efficiency

Polymer preparation unit application

Chemical Treatment Systems

Industrial Wastewater Treatment Systems

– Grease Industries

– Sugar Industries

– Leather Industries

Wastewater Treatment Systems

Filtration Systems

Sludge Dewatering;

– Conditioning Chemical or Excess Biological Sludge

Contact us:

Company: Wuxi Dajiang Environmental Technology Co., Ltd. DAGYEE

Phone/WhatsApp:+8613961861780

Email: info@dagyee.com

Website: www.dagyee.com

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China