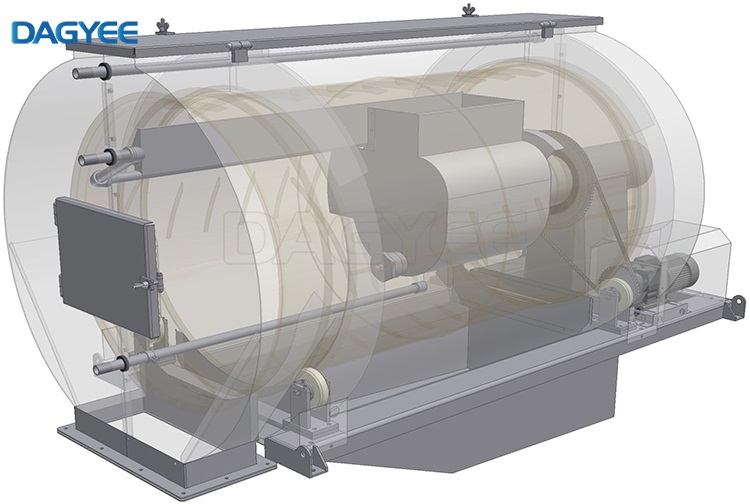

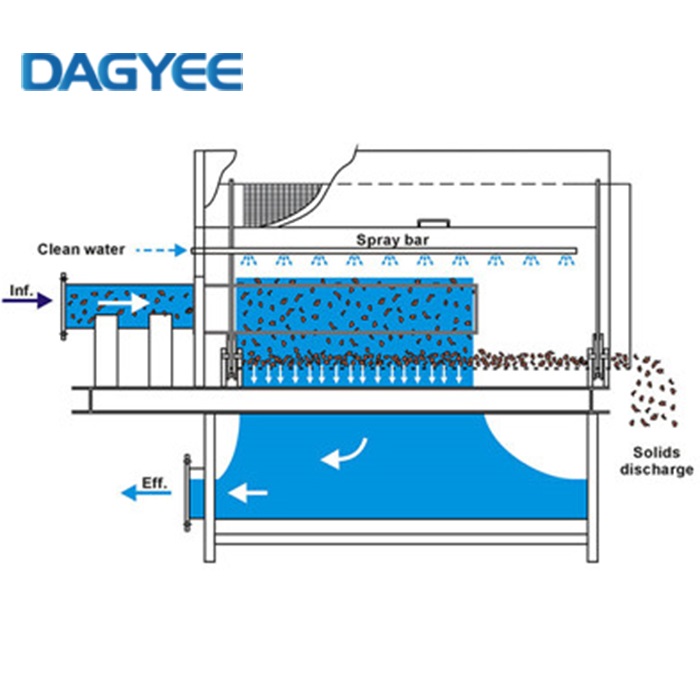

Internally Fed Screens Function

The raw water is fed in the internal rotating surface of the screen. Solids remain on the surface of the screen while the liquid goes through the screen. As the screening cylinder rotates, the solids drop off one diverter flight to the next until they reach the discharge. A spraying/backwash system located on the upper half of the unit, will wash off any solids, grease or other materials sticking to the face of the screen and keep the perforation clean.

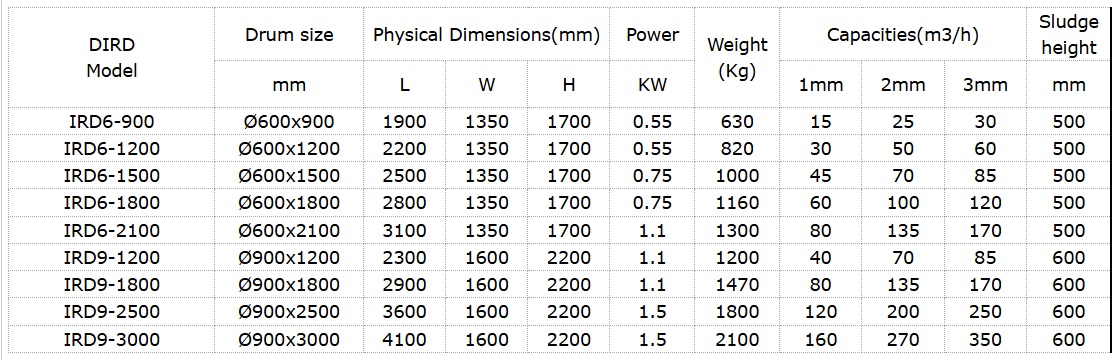

Internally Fed Screens Model

Internally Fed Screens Advantage

Internally Fed Screens Application

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China