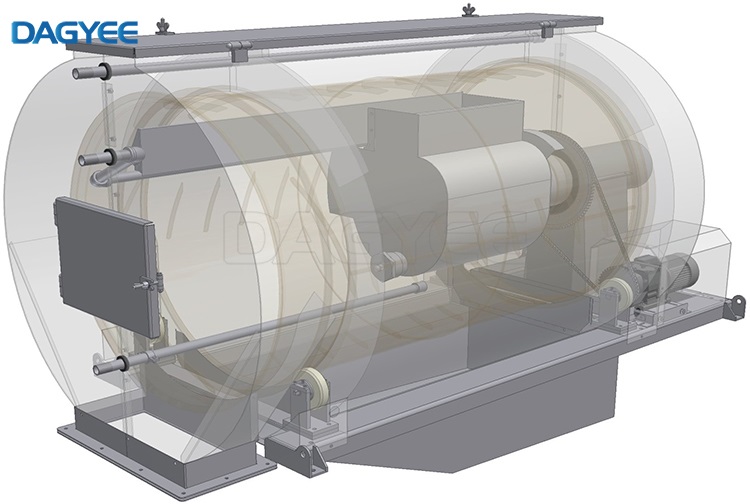

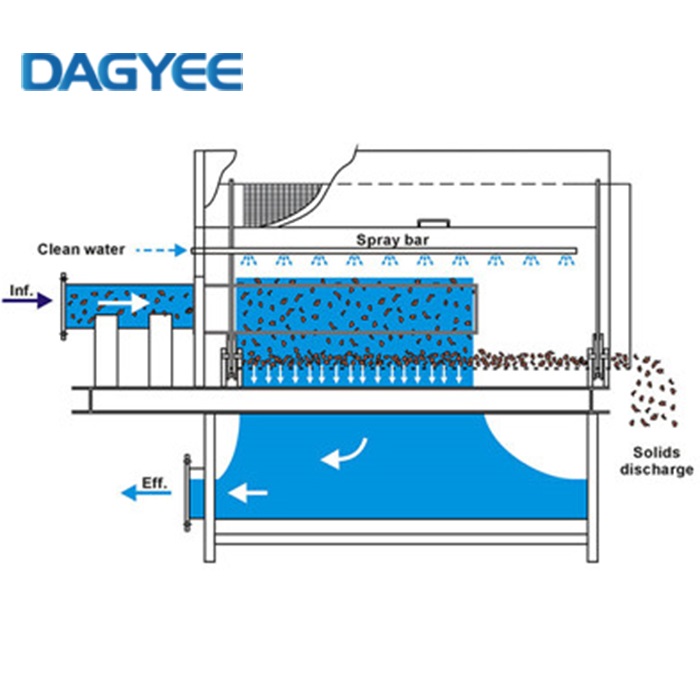

Internally Fed Rotating Drum Screen Function

Internally Fed Screens are individually engineered and designed to meet client specifications with regard to location of influent flow distribution chamber, height, width, gravity or pumped flow, and need for access/ inspection doors and /or odor abatement.

Screen support construction of polymeric trunnions that are of shafted and permanently lubricated sealed bearing design.

The wedge wire or perforated screen with variable slot opening provides solids removal based on client’s specific particle size distribution.

Each system is equipped with an integral sump which can be oversized and/or conformed to meet design and

potential upset conditions.

All stainless steel construction including legs, pans, and other extraneous parts with no hidden add-on costs.

Screening systems are offered with a wide range of electrical control panel options, from basic to sophisticated

control circuitry.

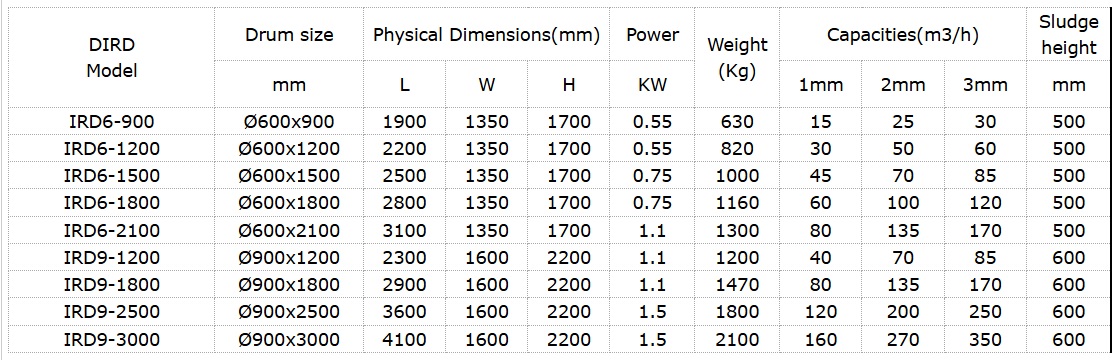

Internally Fed Rotating Drum Screen Model

Internally Fed Rotating Drum Screen Feature

Internally Fed Rotating Drum Screen Application

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China