Product description

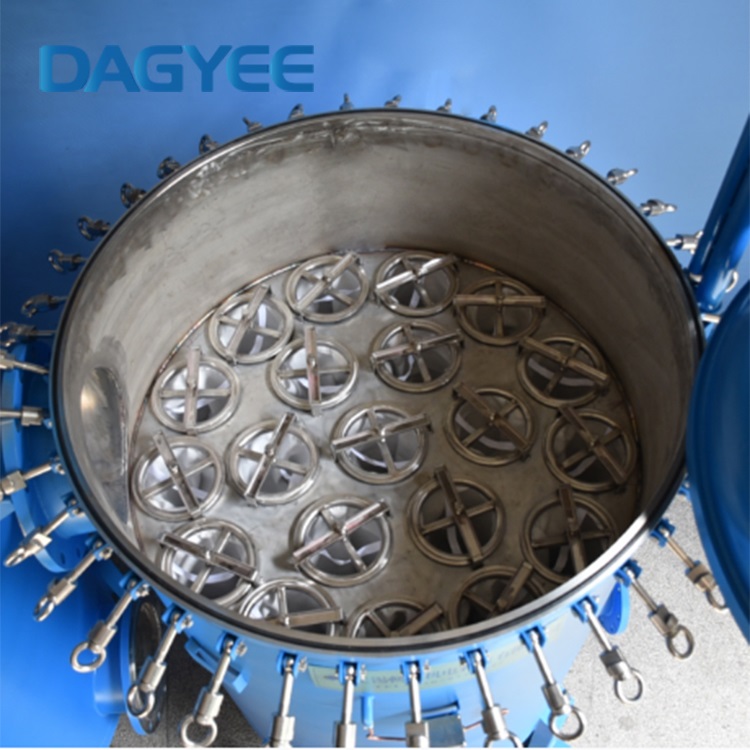

A Multi Cartridge Filter Housing is a large-scale, pressurized vessel designed to house multiple filter cartridges in parallel. It is engineered for high-flow applications where extended filtration cycles, high dirt-holding capacity, and system redundancy are critical. By consolidating multiple cartridges into a single, robust unit, it provides an efficient and compact solution for heavy-duty industrial filtration.

Product function

Handles High Flow Rates: Meets the filtration demands of high-velocity applications.

Holds More Contaminants: Extends filtration cycles and reduces change-out frequency.

Built-in System Redundancy: A single cartridge failure does not halt the entire operation.

Integrated Design: Consolidates multiple filtration points into one unit, simplifying the system.

Product technical

Seal type: O-rings and flat gasket

Sealing material: nitrile rubber(chemitum), silicone, fluorine rubber, usually use silicon

Rubber seal Filter interface: the threaded, clamp(hoop), GB, HG, DIN, ANSI

Filtration accuracy: 1μm - 100 μm

Body material: SS304/SS 316

Single filter Cartridges housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Diameter mm |

|---|---|---|---|---|---|---|

| DYG-1-10" | 0.5 M³/H | 6/120 | Ø65*250 | 1/2" | 380 | Ø89 |

| DYG-1-20" | 1 M³/H | 6/120 | Ø65*500 | 3/4" | 630 | Ø89 |

| DYG-1-30" | 1.5 M³/H | 6/120 | Ø65*750 | 1" | 880 | Ø89 |

| DYG-1-40" | 2 M³/H | 6/120 | Ø65*1000 | 1" | 1130 | Ø89 |

Single microporous filter housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet-Quick Connector | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-C1-10" | 0.5 M³/H | 6/120 | Ø68*250 | 1 1/4" | 608 | Ø102 |

| DYG-C1-20" | 1 M³/H | 6/120 | Ø68*500 | 1 1/4" | 850 | Ø102 |

| DYG-C1-30" | 1.5 M³/H | 6/120 | Ø68*750 | 1 1/4" | 1100 | Ø102 |

| DYG-C1-40" | 2 M³/H | 6/120 | Ø68*1000 | 1 1/4" | 1350 | Ø102 |

5 Cartridges filter Housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-5-10" | 2.5 M³/H | 6/150 | Ø65*250 | 3/4" | 550 | Ø219 |

| DYG-5-20" | 5 M³/H | 6/150 | Ø65*500 | 1" | 850 | Ø219 |

| DYG-5-30" | 7.5 M³/H | 6/150 | Ø65*750 | 1 1/2" | 1100 | Ø219 |

| DYG-5-40" | 10 M³/H | 6/150 | Ø65*1000 | 2" | 1390 | Ø219 |

5 Cartridges filter Housings with flange

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-5F-10' | 2.5 M³/H | 0-1.0MPa | Ø65*250 | 3/4" | 550 | Ø219 |

| DYG-5F-20' | 5 M³/H | 0-1.0MPa | Ø65*500 | 1" | 850 | Ø219 |

| DYG-5F-30' | 7.5 M³/H | 0-1.0MPa | Ø65*750 | 1 1/2" | 1100 | Ø219 |

| DYG-5F-40' | 10 M³/H | 0-1.0MPa | Ø65*1000 | 2" | 1390 | Ø219 |

Single bag filter housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-1-1S | 18 M³/H | 12/150 | Ø180*410 | 1 1/2" flange | 1040 | Ø219 |

| DYG-1-2S | 36 M³/H | 12/150 | Ø180*810 | 2" flange | 1300 | Ø219 |

| DYG-1-4S | 10 M³/H | 12/150 | Ø105*380 | 1 1/2" BSP female | 850 | Ø133 |

| DYG-1K-1S | 18 M³/H | 12/150 | Ø180*410 | 1 1/2"flange | 1010 | Ø219 |

Multi Bag Filter Housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-2D-2S | 70 M³/H | 12/150 | Ø180*810 | 2" | 1600 | Ø420 |

| DYG-3D-2S | 100 M³/H | 12/150 | Ø180*810 | 3" | 1800 | Ø506 |

| DYG-4D-2S | 130 M³/H | 12/150 | Ø180*810 | 4" | 1800 | Ø506 |

| DYG-6D-2S | 200 M³/H | 12/150 | Ø180*810 | 4" | 2100 | Ø650 |

| DYG-8D-2S | 250 M³/H | 12/150 | Ø180*810 | 5" | 2100 | Ø710 |

| DYG-12D-2S | 400 M³/H | 12/150 | Ø180*810 | 6" | 2100 | Ø910 |

High-Efficiency Processing, Ensures Production: Capable of handling high-flow conditions that single-cartridge housings cannot meet, directly supporting main production lines and boosting overall capacity.

Extended Service Cycles, Reduces Costs: The high dirt-holding capacity significantly extends intervals between cartridge changes, reducing consumable costs and maintenance labor expenses.

System Redundancy, Ensures Operational Reliability: Even if one or several cartridges become clogged or damaged, the remaining cartridges continue to operate, providing a buffer for scheduled maintenance and effectively preventing unplanned downtime.

Top-Service Design: Features a large, removable top head or bolted cover for easy access to all cartridges simultaneously, simplifying maintenance.

Integrated Accessories: Often includes accessories like pressure gauges (inlet/outlet), vent valves, and drain valves for operational control and safety.

Scalability: Available in various sizes and cartridge counts (e.g., 3, 7, 12, 21-cartridge models) to match specific flow rate requirements.

Product application

Food & Beverage: Water purification, ingredient filtering, wine and beer stabilization, edible oil processing.

Pharmaceutical & Biotech: Purification of water for injection (WFI), process fluids, solvent filtration, sterile venting.

Chemicals & Petrochemicals: Chemical purification, catalyst recovery, pre-filtration for membranes.

Electronics: Ultra-pure water production for semiconductor and PCB manufacturing.

Metalworking & Plating: Coolant filtration, pre-treatment of plating baths.

General Industrial: Water treatment, hydraulic and lubricating oil protection, compressed air and gas filtration.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China