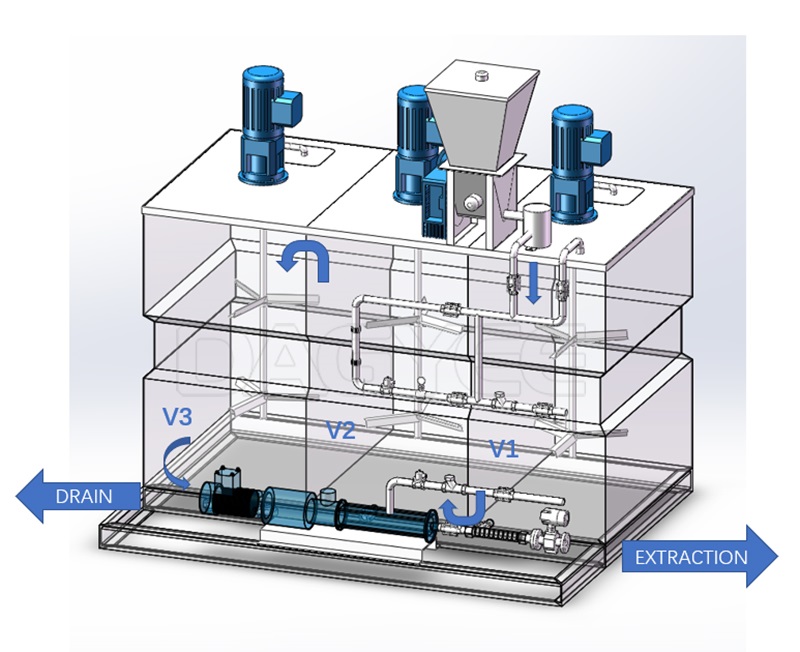

It is a pre-engineered polymer mixing system made for the water and wastewater markets. Designed as an in-line unit, it can be customized to meet most liquid polymer applications utilizing tubing or diaphragm pump technologies depending on the application requirement or customer preference. The unique mixing chamber allows for complete makedown of the neat or diluted polymer to guarantee a problem-free injection.

It applies a jet mixer, using high-speed water power to break up the polymer powder which will improve the fineness, increase the contact of water and polymer powder and reduce the time of dissolution. The equipment adopts the design of three tank overflow combination, that is, mixing, aging and storing. The proportion difference caused by the gravity and solubility will automatically separate the dissolved and undissolved solution. Homogeneous degree of the solution will be improved by stirring of the low-speed agitator afterwards.

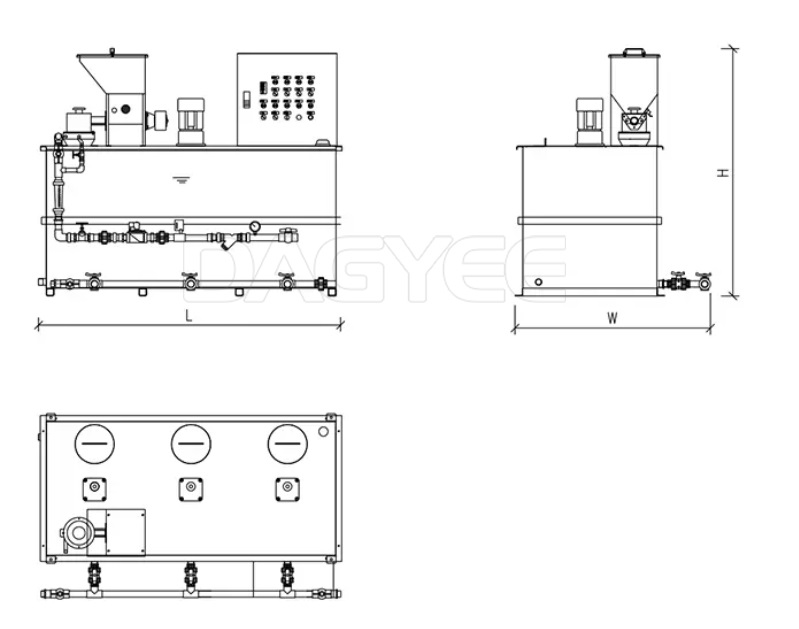

Polymer preparation unit model

| Model | Capacity L/H | Volume L | Timing H | Dimensions MM | Weight KG | Power KW |

|---|---|---|---|---|---|---|

| DT300 | 300 | 450 | 0.6-1 | 1500*1000*500 | 300 | 1.8 |

| DT500 | 500 | 750 | 0.6-1 | 1500*1000*650 | 420 | 1.8 |

| DT1000 | 1000 | 1500 | 0.6-1 | 2000*1000*900 | 500 | 2.8 |

| DT1500 | 1500 | 2250 | 0.6-1 | 2000*1200*900 | 620 | 3 |

| DT2000 | 2000 | 3000 | 0.6-1 | 2500*1200*1000 | 800 | 3.9 |

| DT3000 | 3000 | 4500 | 0.6-1 | 3000*1500*1000 | 950 | 5.3 |

| DT5000 | 5000 | 7500 | 0.6-1 | 5000*1500*1000 | 1250 | 7 |

| DT10000 | 10000 | 15000 | 0.6-1 | 4800*1800*2000 | 3600 | 7 |

High efficiency mixers: Provide a low flow mixing for a homogeneous flocculant polymerisation without mechanical deterioration.

Optimised process: Visual access to the process and alarms, fieldbus distributed control (optional) provides informative and easy to access equipment and status application updates, controlled costs.

Option dual: Two-in-one solution, to prepare powder or Liquid Polymers. Ideal solution for wastewater plants located in areas subject to population changes.

1. Fully automatic operation including automatic dosing, dissolving and feeding

2. The highly precise dry polymer dosing device and the well-designed heater device can prevent the polymer from caking

3. The dosage of dry powder and water can be adjustable, so the solution with any concentration can be prepared

4. Optional: Vacuum feeding machine

5. Optional: on-line dilution system

6. Tank material: SS304 or SS316l, Polypropylene PP, FRP etc

Polymer preparation unit application

The Polymer Preparation Unit (PPU) by Enviroflex is a fully automatic system designed for the continuous preparation and dosing of polymer (flocculant) solution used in a wide range of applications, including:

Municipal and industrial wastewater treatment

Mining and mineral processing (tailings, thickening)

Oil & gas operations (drilling fluid conditioning, produced water treatment)

Chemical and food processing industries

Contact us:

Company: Wuxi Dajiang Environmental Technology Co., Ltd. DAGYEE

Phone/WhatsApp:+8613961861780

Email: info@dagyee.com

Website: www.dagyee.com

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China