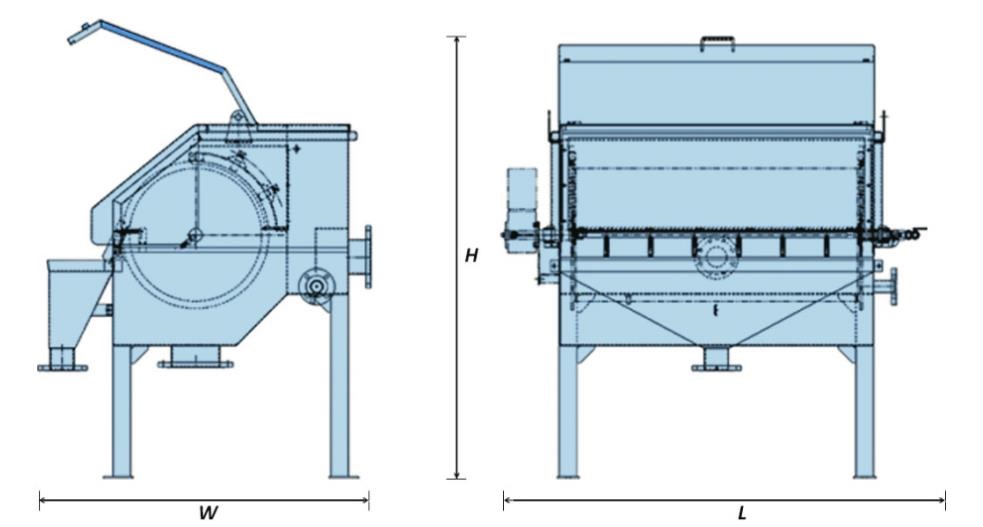

Externally rotary fed drum screen description

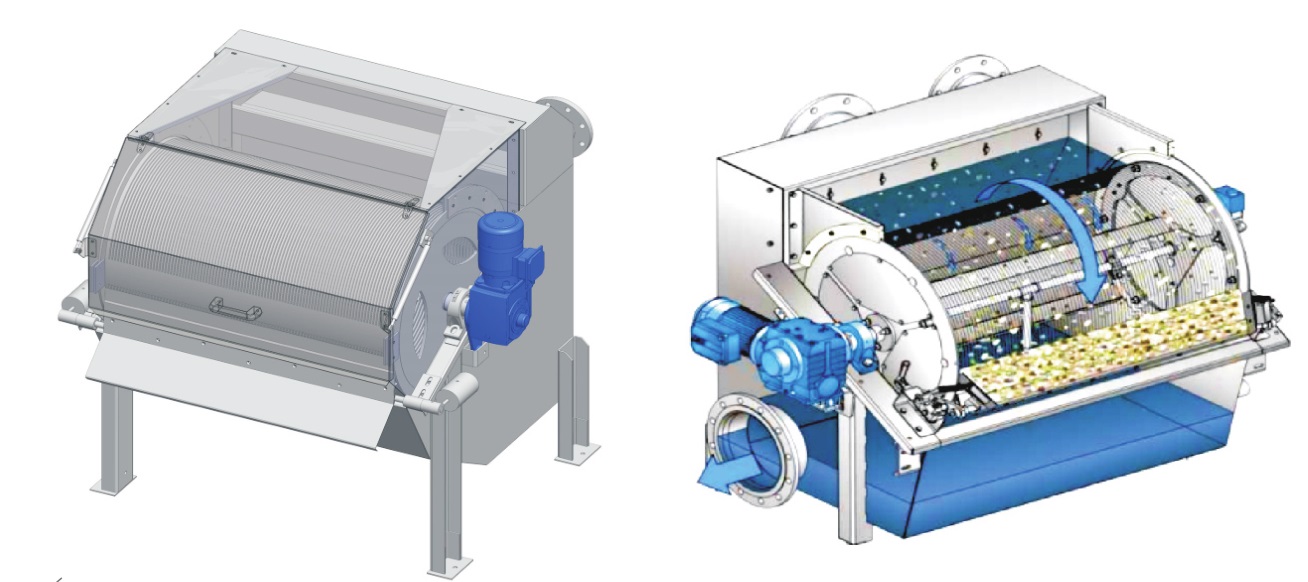

It utilizes gravity to evenly distribute influent flow across the externally fed rotating drum, effectively managing variations in solids concentration.

This controlled distribution enhances solids separation and reduces the risk of overload, maintaining reliable performance even with changing wastewater conditions.

Drum rotation, combined with a precision spray cleaning system, eliminates buildup and maintains optimal screening efficiency without manual cleaning.

This external-feed design simplifies maintenance by ensuring solids remain on the drum's outer surface, protecting internal components from debris and wear.

The screened effluent moves swiftly downstream, minimizing headloss and enhancing overall system efficiency.

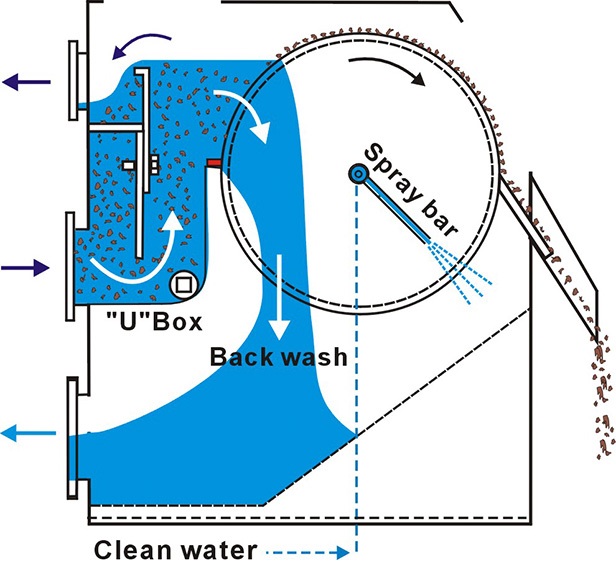

Externally rotary fed drum screen function

Externally fed rotary drum screens use the outside periphery of the cylinder which is rotating on a horizontal axis.

The solid wastes remain on the surface of the drum and when it comes to the lower part with the effect of rotation, it is thrown out of the system by a doctor blade.

The filtrated wastewater enters inside the drum and reaches the collecting chamber on the equipment.

An internal spray backwash system is placed into the drum to clean the system properly when it is necessary.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. Most efficient screening technology.

2. Capture everything.

3. Structure & Drum in stainless steel.

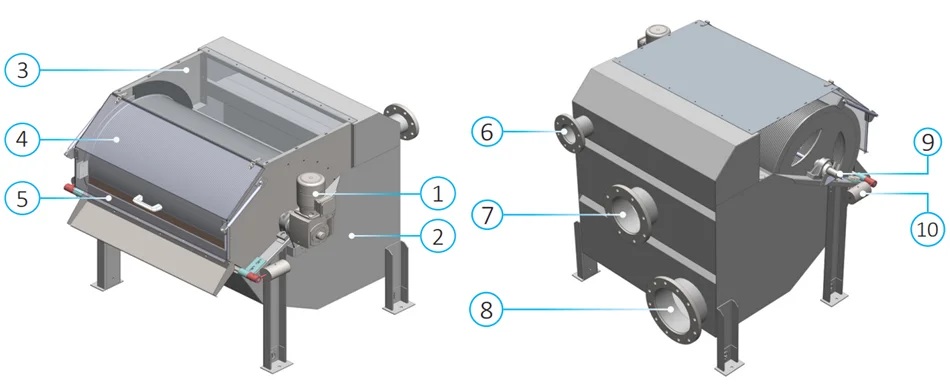

Externally rotary fed drum screen feature

1. Feed chamber with incorporated overflow, designed to allow sewage to cover the entire width of the cylinder.

2. Screening cylinder consisting of a V-shaped profile wound in a spiral around a structure of longitudinal bars.

3. Spillway blade made of wear-resistant material that exerts constant pressure on the cylinder piston.

4. Backwash by means of a device installed in the screening cylinder.

5. Spacing between 0.25 and 6 mm wedge wire or from 1 to 6 mm perforated.

6. Worm geared motor and helical gears.

Externally rotary fed drum screen application

Wastewater In The Paper Mill

Leather Factory

Slaughterhouse

Brewing

Food Industry

Chemical Fiber

Textiles

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China