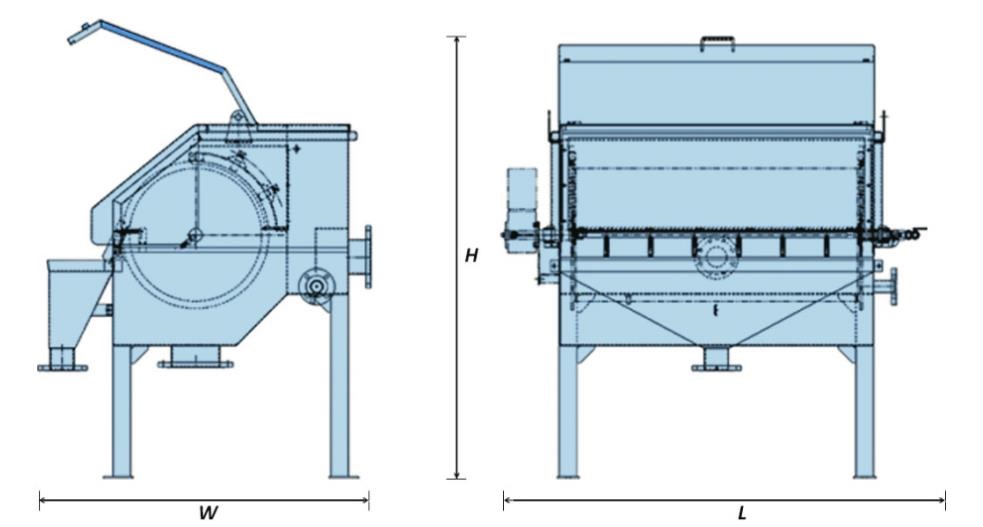

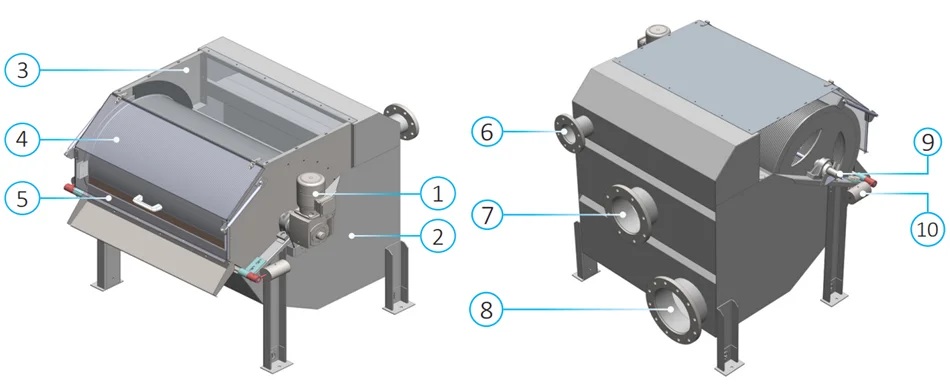

Externally rotary fed drum screen description

It is an externally fed rotary drum screen designed to provide efficient and reliable solids separation in a wide range of wastewater treatment applications.

Ideal for municipal headworks, industrial process water, and sludge screening, the unit delivers high-performance screening with minimal operator attention.

Its rugged stainless steel construction and enclosed, self-cleaning design ensure long-term durability and cleanliness, even in demanding environments.

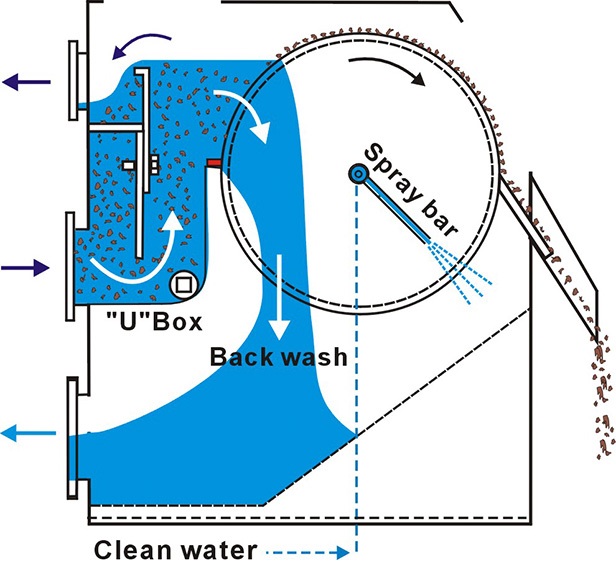

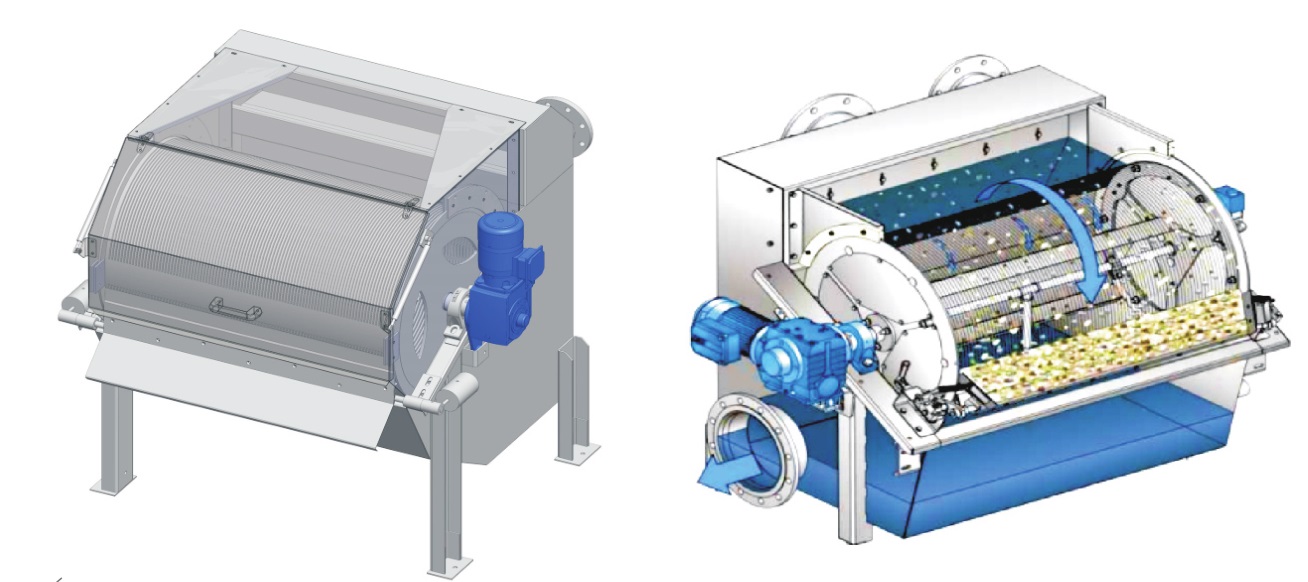

As wastewater flows over the drum’s exterior surface, solids are retained while liquid passes through the screen openings.

The rotating drum is continuously cleaned by an internal spray system, maintaining open screening surfaces and maximizing throughput.

The captured solids are conveyed to discharge, leaving screened effluent ready for downstream treatment.

With a compact footprint, customizable screen sizes, and low maintenance requirements, the Screenmaster ES offers a simple yet effective solution for enhancing plant efficiency and protecting downstream equipment.

Externally rotary fed drum screen function

The drum screen executes fine micro-screening and is installed upstream of small and medium-sized purification plants.

The flow of the suspension for screening meets the surface of the rotary screen perpendicular to the direction of the hole between the bars.

While the filtered liquid passes through the holes of the screen and is discharged into a tank under the cylinder, the solids are trapped on the surface of the same screen and are drawn by rolling friction to a spillway blade that diverts them to a special container.

The bars of the cylinder ar wedge-shaped, permitting the uninterrupted flow of hydraulic pressure and minimizing the risk of solids sticking and causing obstruction.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. Internal backwashing spray.

2. Keeps screen clean for high performance.

3. Multiple unit models.

4. Provide variety for any application.

5. Proven design.

6. With over 1000 installations.

7. Internal water spray.

8. Keeps screen clean from blinding solids and FOG.

Externally rotary fed drum screen feature

1. Slot width: 0.25 ~ 2.50 mm.

2. Wedge wire filter with so-called “slot zero” to ensure drum resistance.

3. Screen in 304 L / 316 L SS.

Externally rotary fed drum screen application

This advanced solid-liquid separation device is designed for continuous and automatic removal of debris in wastewater treatment processes.

It is ideal for:

Municipal wastewater treatment plants

Residential and community sewage pretreatment systems

Pumping stations, waterworks, and power plants

Industrial wastewater treatment across sectors such as: textile, printing and dyeing, food processing, fishery, papermaking, winemaking, slaughterhouses, leather factories, and more.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China