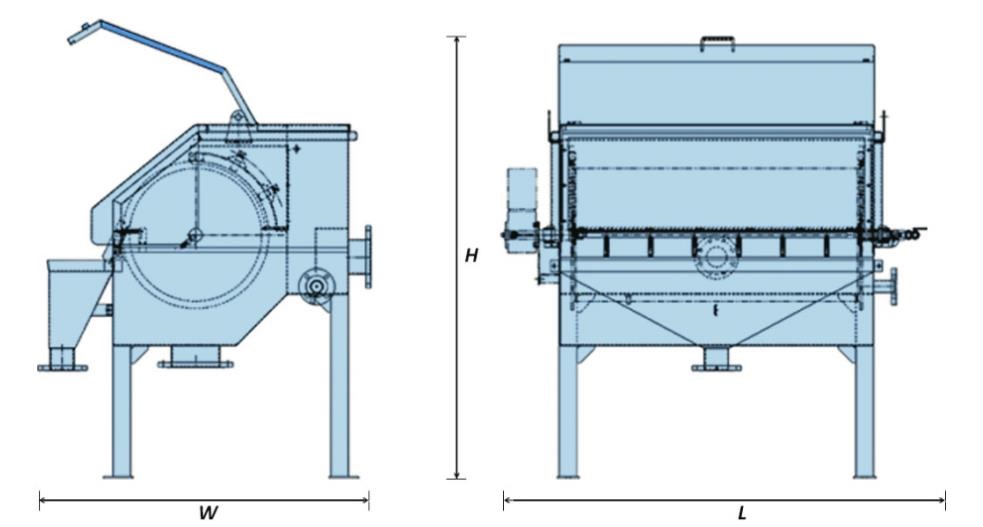

Externally rotary fed drum screen description

Externally fed drum screen provides advanced solids removal for wastewater treatment, specifically designed for municipal and industrial facilities.

Its durable stainless steel structure and automatic self-cleaning mechanism offer reliable, low-maintenance performance, effectively handling solids separation under demanding conditions.

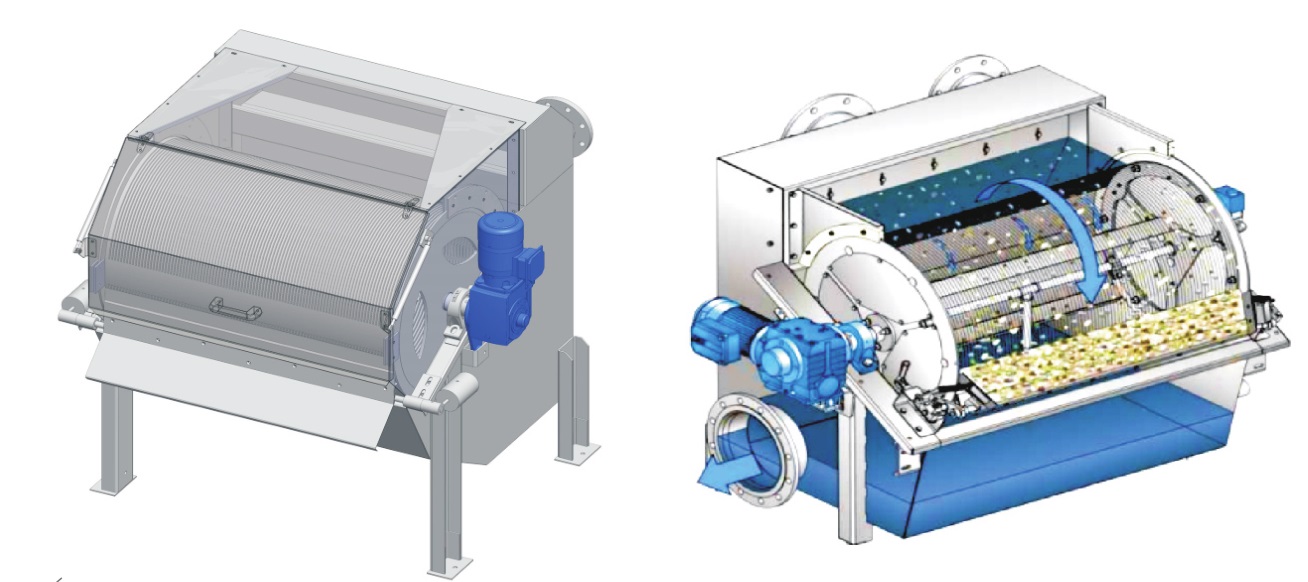

Influent flows evenly across the rotating drum surface, capturing solids on the exterior screen while filtered water passes through.

Continuous drum rotation and internal spray cleaning prevent clogging, delivering uninterrupted operation.

The compact, enclosed design minimizes odor, reduces maintenance needs, and optimizes overall treatment efficiency.

Externally rotary fed drum screen function

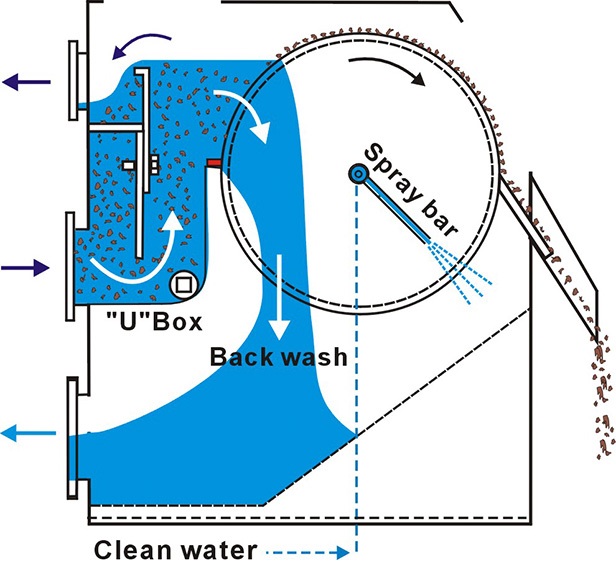

The screen is externally fed so that influent is directed under a baffle, then upward and over the length of the cylinder.

The natural action of wastewater cascading through the screen creates a powerful backwash, which results in a continuously clean surface.

Solids are caught on the outside of the screen surface and are removed by a tensioned doctor blade.

Opening sizes are available from 0.010" (.250 mm) to 0.100" (2.54 mm).

Capacities range from 60 GPM (13.6 M3/H) to 7800 GPM (1771 M3/H) in a single unit. Additional models are available to handle higher capacities.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

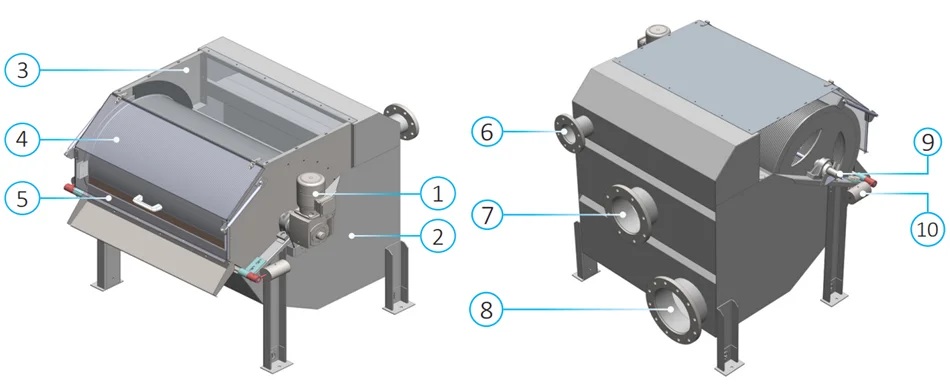

1. Self-cleaning wedgewire drum screen.

2. With doctor blade works 24/7 to reduce operator attention.

3. Counter weighted primary doctor blade.

4. Need no adjustments and reduces maintenance.

5. Automatic Doctor Blade Cleaner (ADBC).

6. Clean primary doctor blade.

7. Stainless steel construction.

8. Improve screen life and durability.

Externally rotary fed drum screen feature

1. Slot width: 0.25 ~ 2.50 mm.

2. Wedge wire filter with so-called “slot zero” to ensure drum resistance.

3. Screen in 304 L / 316 L SS.

Externally rotary fed drum screen application

This advanced solid-liquid separation device is designed for continuous and automatic removal of debris in wastewater treatment processes.

It is ideal for:

Municipal wastewater treatment plants

Residential and community sewage pretreatment systems

Pumping stations, waterworks, and power plants

Industrial wastewater treatment across sectors such as: textile, printing and dyeing, food processing, fishery, papermaking, winemaking, slaughterhouses, leather factories, and more.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China