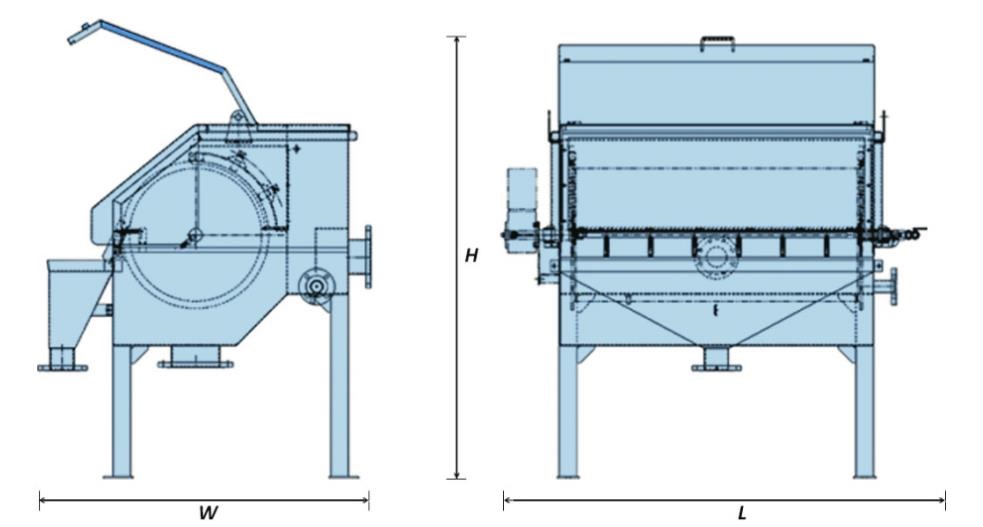

Externally rotary fed drum screen description

It executes fine micro-screening and is installed upstream of small and medium-sized purification plants.

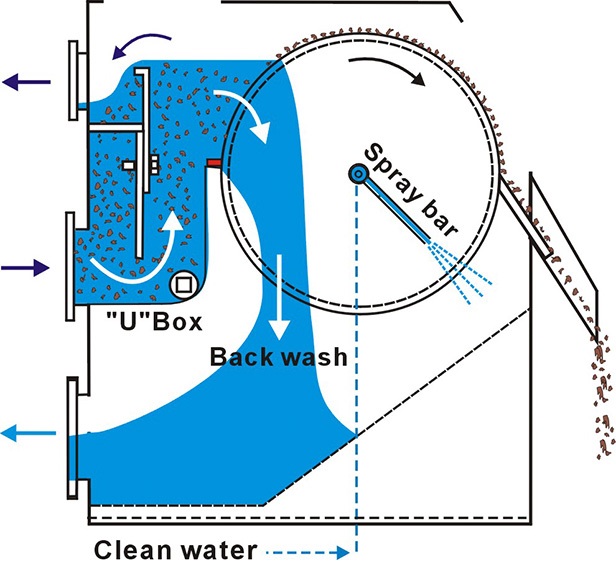

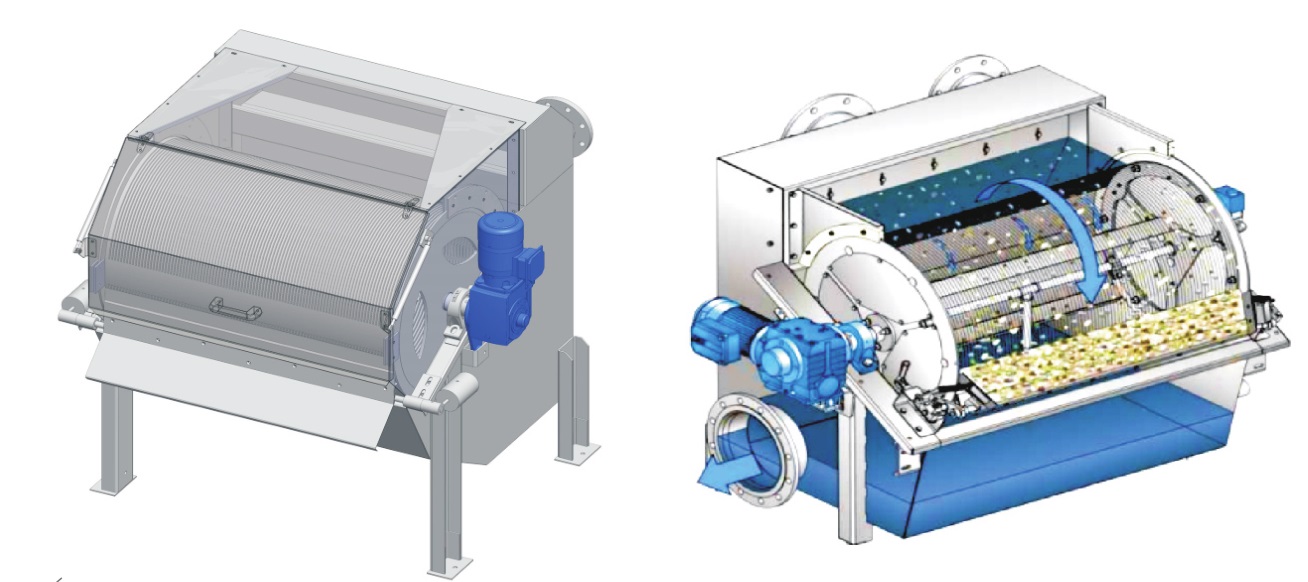

The flow of the suspension for screening meets the surface of the rotary screen perpendicular to the direction of the hole between the bars.

While the filtered liquid passes through the holes of the screen and is discharged into a tank under the cylinder, the solids are trapped on the surface of the same screen and are drawn by rolling friction to a spillway blade that diverts them to a special container.

The bars of the cylinder are wedge-shaped, permitting the uninterrupted flow of hydraulic pressure and minimizing the risk of solids sticking and causing obstruction.

Externally rotary fed drum screen function

Utilizing the external surface of a wedge wire drum screen, the wastewater is pumped and distributed equally to the outer surface.

The wastewater flows through the screen and out from the bottom part while the solid waste is captured and transported to the opposite side of the drum screen where it gets removed from screen surface and discharged with the help of a doctor blade.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

High Filtration Efficiency

Effectively removes fine particles (down to 10-50 microns) from water, ensuring high-quality filtrate.

Continuous Automated Operation

Rotary drum design allows continuous filtration without interruptions, reducing manual labor.

Low Energy Consumption

Operates with minimal power due to its simple mechanical structure and efficient water flow.

Self-Cleaning Function

Automatic backwashing or brushing systems prevent clogging, maintaining consistent performance.

Space-Saving Design

Compact size and vertical drum configuration make it suitable for limited installation spaces.

Durable Construction

Built with corrosion-resistant materials (e.g., stainless steel) for long-term reliability in harsh environments.

Adaptable to Various Water Types

Works well in industrial wastewater, aquaculture, municipal sewage, and stormwater applications.

Cost-Effective Maintenance

Reduced downtime and easy access to components simplify repair and replacement.

Environmentally Friendly

Low water and chemical usage in backwashing processes align with sustainable practices.

Customizable Performance

Adjustable drum speed and filter mesh sizes meet specific operational requirements.

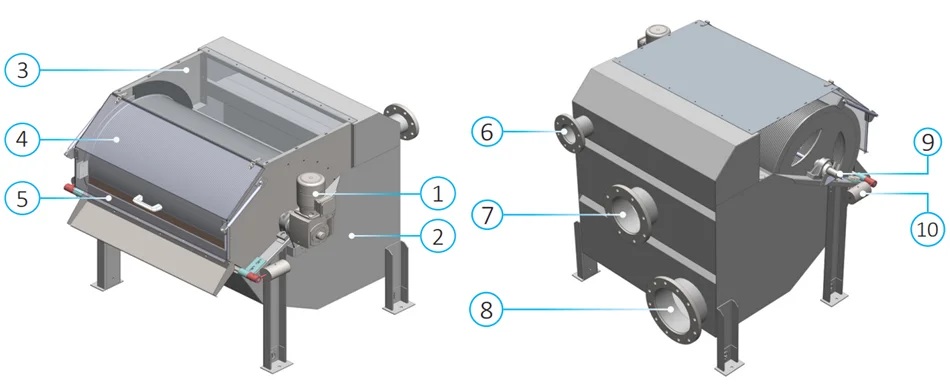

Externally rotary fed drum screen feature

1. No odor and water splash problem due to completely covered system.

2. Automatic operation in high efficiency.

3. Low energy consumption.

4. Easy clean-up and minimum maintenance.

5. Wide range of capacity.

6. Compact design.

Externally rotary fed drum screen application

vegetable, fruit and potato processing industry

sugar industry

meat and poultry processing / abattoirs / rendering industry

fish and shellfish processing industry

brewing, malting and beverage industry / distilleries

horticulture industry

zoos

textile industry / laundries

paper and pulp industry

exhaust gas cleaning

tanneries

waste recycling industry

bioenergy industry

sewage water treatment

drinking water plants

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China