Externally rotary fed drum screen description

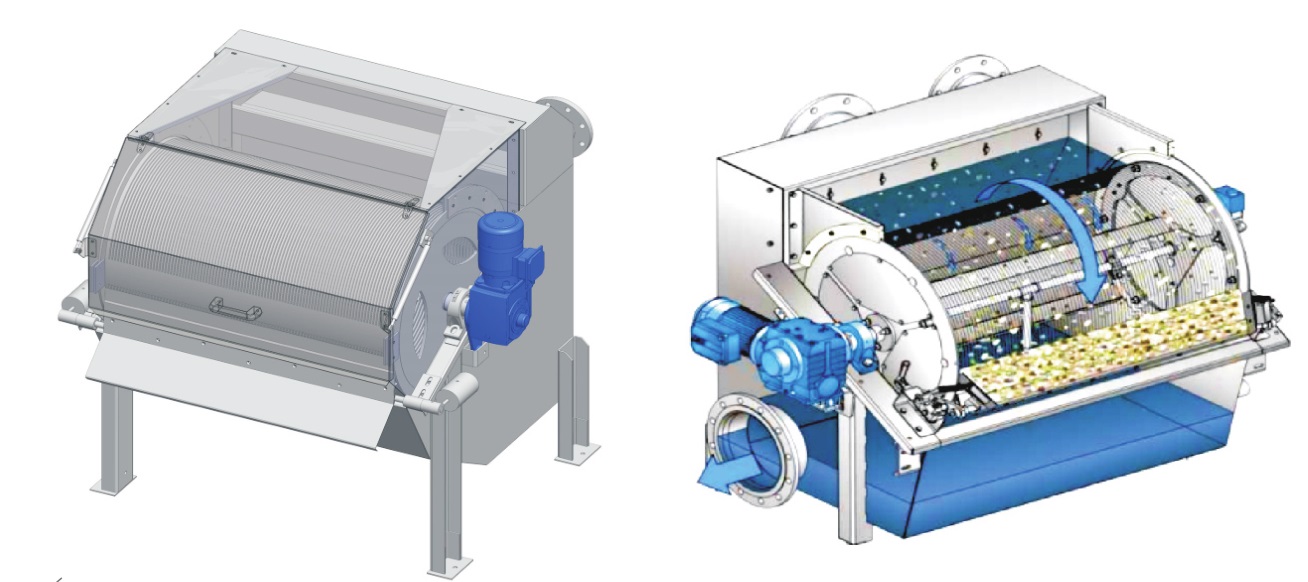

This stainless steel wedge wire screen is self-cleaning by nature due to constant back washing.

This often allows for only intermittent use of the spray bar cleaning system, reducing water usage.

Not well suited for fine screening of high flows, but the use of the doctor blade system makes this mechanical screen well suited when oils and grease are present.

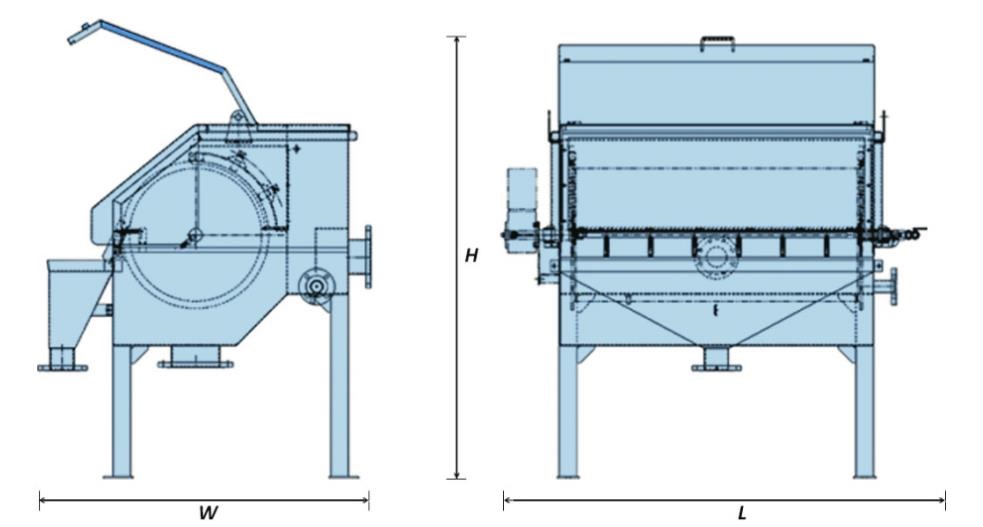

Sized based on peak flow, solids and fats, oils, grease loadings in the wastewater/process water, these units can be configured with a variety of piping scenarios, overall dimensions and slot openings.

Bypass configurations allow for bypass of overflow when upset conditions occur.

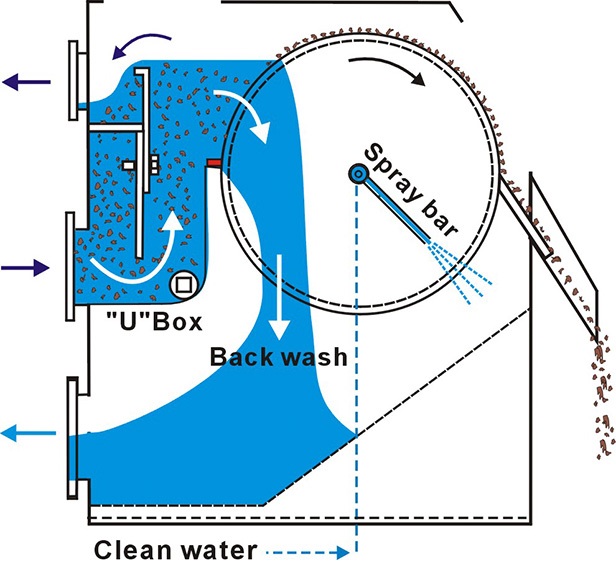

Externally rotary fed drum screen function

The suspended matter in the sewage retained on the rotating drum, and with the rotation of the drum, it is sent to the discharging end of the other side from the inlet end, which is shoveled down by the unloading device.

The time relay in control cabinet controls the back flush solenoid valve to open and close periodically so that to clean the blockage between the drum bars.

The integral design, strong construction and high quality stainless steel material ensure the equipment can long-term operate with trouble-free and low energy consumption. Simple maintenance.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. No odor and water splash problem due to completely covered system.

2. Automatic operation in high efficiency.

3. Low energy consumption.

4. Easy clean-up and minimum maintenance.

5. Wide range of capacity.

6. Compact design.

7. Less space requirements.

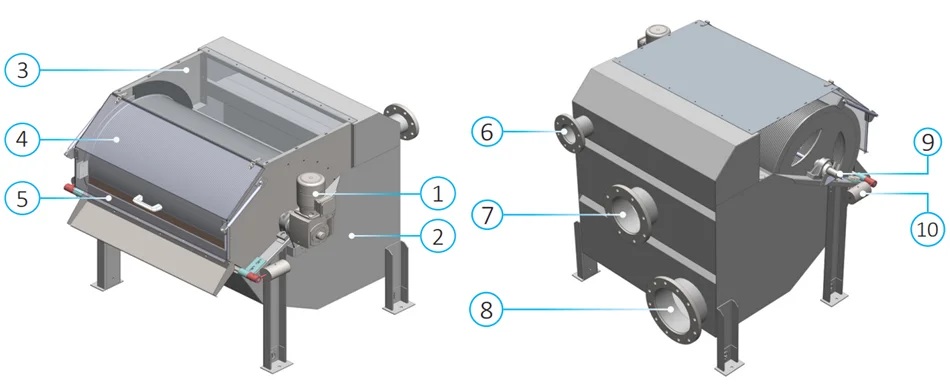

Externally rotary fed drum screen feature

1. SS304 stainless steel member;

2. Integral structure;

3. External spray system;

4. Sealing cover plate;

5. Frequency control range 4-20 rpm;

6. Automatic blow slag;

7. Timed back flush.

Externally rotary fed drum screen application

Wastewater Treatment: Removing solids from municipal and industrial wastewater.

Food Processing: Separating solids from liquid streams in food production.

Pulp and Paper Industry: Fiber recovery and wastewater treatment.

Agriculture: Manure processing and irrigation water filtration.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China