Static Mixers

A static mixer is a type of device that employs forced flow to merge both miscible and immiscible materials into a uniform mixture. It comprises a tube equipped with mixing blades or elements that alter the flow's direction and movement, ensuring thorough blending of all gases, fluids, and liquids. Fluids can enter a static mixer through various means, with pumps and gravity being two of the most prevalent methods.

In contrast to other mixing methods, static mixers do not incorporate moving components, thereby eliminating the need for maintenance. This design minimizes energy usage and negates the requirement for electrical elements. Featuring helical barriers that compel the flow to integrate, inline mixers, also known as static mixers, are utilized in manufacturing operations and processing lines with a continuous material flow. They ensure the rapid and effective mixing of a constant stream of liquids or gases.

Static Mixer Function

Static mixers are named as such because they have no moving parts. The mixing elements located inside the pipe do not move or twist. Instead, the mixing elements force the process fluids to flow in certain ways that promote mixing. For turbulent flow applications of both miscible and immiscible fluids, the mixing mechanisms are fluid splitting and radial mixing. For laminar flow applications, the main mixing mechanism is simply flow splitting.

Static mixers do not need any direct energy. They do,

however, create a pressure loss in the line. This pressure loss is overcome by a pump, upstream of the mixer.

In most cases, static mixers are capable of providing a

uniform mixture with a relatively small pressure drop. (Of course there are exceptions to this rule, such as if the process fluid has a high viscosity.)

Static Mixer SK Series Model

|

Model |

Dg(mm) |

dh(mm) |

Q(m3/h) |

|

SK-5/10 |

10 |

5 |

0.15-0.3 |

|

SK-7.5/15 |

15 |

7.5 |

0.3-0.6 |

|

SK-10/20 |

20 |

10 |

0.6-1.2 |

|

SK-12.5/25 |

25 |

12.5 |

0.9-1.8 |

|

SK-16/32 |

32 |

16 |

1.4-3.2 |

|

SK-20/40 |

40 |

20 |

2.2-4.5 |

|

SK-25/50 |

50 |

25 |

3.5-7.0 |

|

SK-32.5/65 |

65 |

32.5 |

5.9-12 |

|

SK-40/80 |

80 |

40 |

9-18 |

|

SK-50/100 |

100 |

100 |

14-28 |

|

SK-62.5/125 |

125 |

125 |

22-44 |

|

SK-75/150 |

150 |

150 |

31-64 |

|

SK-100/200 |

200 |

200 |

56-110 |

|

SK-125/250 |

250 |

250 |

88-177 |

|

SK-150/300 |

300 |

300 |

127-255 |

|

SK-175/350 |

350 |

350 |

173-346 |

|

SK-200/400 |

400 |

400 |

226-452 |

|

SK-250/500 |

500 |

500 |

353-706 |

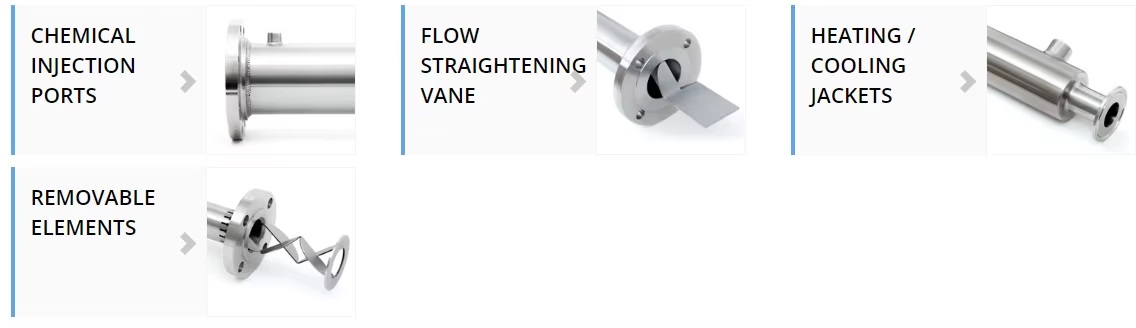

Static Mixer Options

Static Mixer Benefits

Maintenance-Free

DAGYEE Static Mixers are built to last using industrial grade materials specifically tailored to your application.

Low Energy Requirements

Because static mixers are motionless by design, all the energy required to provide a perfect blend is provided by the energy of the flow stream.

Custom-Designed for Your Application

All DAGYEE Static mixers can be custom-tailored to fit your requirements.

Low-Cost

DAGYEE Static Mixers are a low-cost alternative to traditional tank mixers both at purchase and during the mixer's lifetime. There are no running costs associated with operating a DAGYEE Static Mixer on top of running your existing pipeline.

No Moving Parts

Unlike traditional mixers, static mixers remain motionless during the mixing process.

Quick Delivery

DAGYEE maintains complete control over its production process. All static mixers are built in-house at DAGYEE's manufacturing facility outside Chicago and can be manufactured to meet your project schedule.

Static Mixer Applications

Typical applications seen in the water/wastewater industries are mixing of polymer, sodium permanganate, potassium permanganate, sodium hypochlorite, aqueous chemicals, alum, coagulant, chlorine, acid, aluminum sulphate, CO2 gas, NaOH, NaOCI, HCL, antiscalant, flocculant, oily sludge, polyelectrolyte.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China