Static Mixers

In-line static mixers are specialty mixers installed in the line and mix fluids as you pump them through a pipeline. The fluid moves through the mixer in an alternating/clockwise counterclockwise motion to ensure a homogeneous product. They are virtually maintenance free and need no spare parts for long-lasting use. Choose from disposable, pipe, PVC, tube, and sanitary in-line static mixers.

Static Mixer Function

The mixing element or tabs causes turbulence in the mixer housing which will mix chemicals added either prior to the mixer or through an injection port on the housing of the Mixer. The process media will be 95% mixed within 3D (pipe diameters) of the mixer exit, this is called CoV or Coefficient of Variation.

The target CoV for Static Mixers is a CoV of 0.5 or 95% Mixed at 3D (Pipe Diameters) from the mixer exit.

There is no typical Static Mixer design, there are various designs available to meet the specific applicationl

Helical Coil mixers for the Chemical Pharmaceutical and Food Industries,

Tab Mixers for the Water Industry – Tab Mixers like the Kenics HEV, WVM and UTS Mixers have the mixing elements (Tabs) mounted on the wall of the mixer housing and are whats called an open design which means that they are less likely to block, they have a lower pressure drop than Helical Coil Mixers.

Static Mixer SK Series Model

|

Model |

Dg(mm) |

dh(mm) |

Q(m3/h) |

|

SK-5/10 |

10 |

5 |

0.15-0.3 |

|

SK-7.5/15 |

15 |

7.5 |

0.3-0.6 |

|

SK-10/20 |

20 |

10 |

0.6-1.2 |

|

SK-12.5/25 |

25 |

12.5 |

0.9-1.8 |

|

SK-16/32 |

32 |

16 |

1.4-3.2 |

|

SK-20/40 |

40 |

20 |

2.2-4.5 |

|

SK-25/50 |

50 |

25 |

3.5-7.0 |

|

SK-32.5/65 |

65 |

32.5 |

5.9-12 |

|

SK-40/80 |

80 |

40 |

9-18 |

|

SK-50/100 |

100 |

100 |

14-28 |

|

SK-62.5/125 |

125 |

125 |

22-44 |

|

SK-75/150 |

150 |

150 |

31-64 |

|

SK-100/200 |

200 |

200 |

56-110 |

|

SK-125/250 |

250 |

250 |

88-177 |

|

SK-150/300 |

300 |

300 |

127-255 |

|

SK-175/350 |

350 |

350 |

173-346 |

|

SK-200/400 |

400 |

400 |

226-452 |

|

SK-250/500 |

500 |

500 |

353-706 |

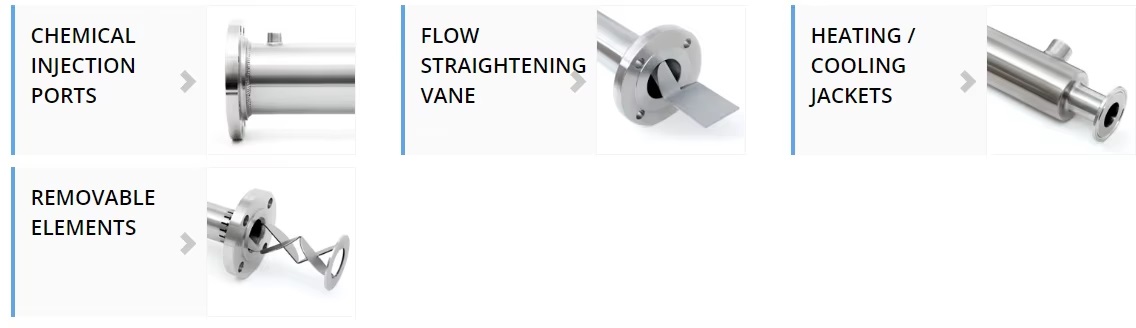

Static Mixer Options

Static Mixer Benefits

DAGYEE maintains complete control over its production process. All static mixers are built in-house at DAGYEE's manufacturing facility outside Chicago and can be manufactured to meet your project schedule.Static mixers deliver a high level of mixing efficiency, therefore the consumption of dosed chemicals and formation of byproducts can be dramatically reduced.

They eliminate the need for tanks, agitators, moving parts and direct motive power and they allow to gain highly efficient mixing with low energy consumption.

The energy required for mixing is efficiently extracted as pressure drop from the fluid flow through the elements. Mixers are invariably installed in existing systems without reducing the capacity of existing pumps.

The installation is very easy; no special skills are required other than normal engineering skills.

Mixers have no moving parts and are virtually maintenance free.

Static Mixers are available in all standard pipe sizes and, in the case of open channel designs, are available in any size with no upper limit.

Each Static Mixer is carefully designed to meet the specific requirements of each application.

Static Mixer Applications

Water and wastewater treatment:

Coagulation processes, e.g. for phosphorous removal from waste water

Chemical dosing

Representative sampling

Aeration of drinking water

PH control

Disinfection of drinking water, e.g. chlorination and dechlorination

Diluting flocculants and mixing with water, wastewater or sludge

Ozone injection and mixing

Desalination of seawater Reverse Osmosis Systems

Oil, gas and petrochemical industries

Measurement of water content of crude oil in pipelines

Desalting crude oil with water

Diluting ployacrylamide for enhanced recovery

Mixing additives into gasoline or fuel oil

Adjusting the viscosity of heavy fuel oil with gas oil

Continuous process industry:

Plastics, fibres

PH control

Resins, adhesives, epoxies

Colours, hardeners

Detergents

Food and pharmaceutical

Mixing CO2 into fruit juices, wine or coffee extract

Mixing milk wit acids

Diluting molasses with water

Diluting concentrates and mixing flavourings

Pulp and paper:

Acid and caustic dilution

PH control

Blending

Low consistency bleaching

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China