Externally rotary fed drum screen description

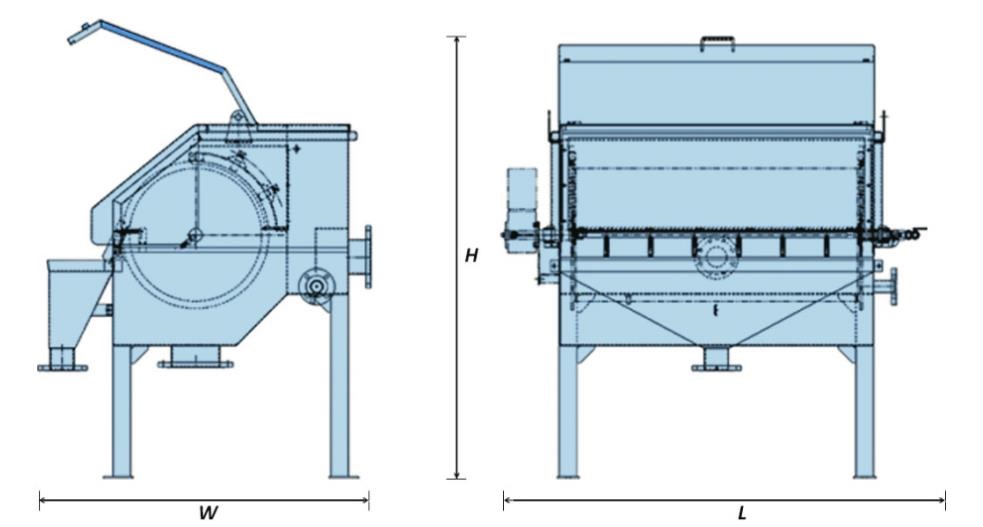

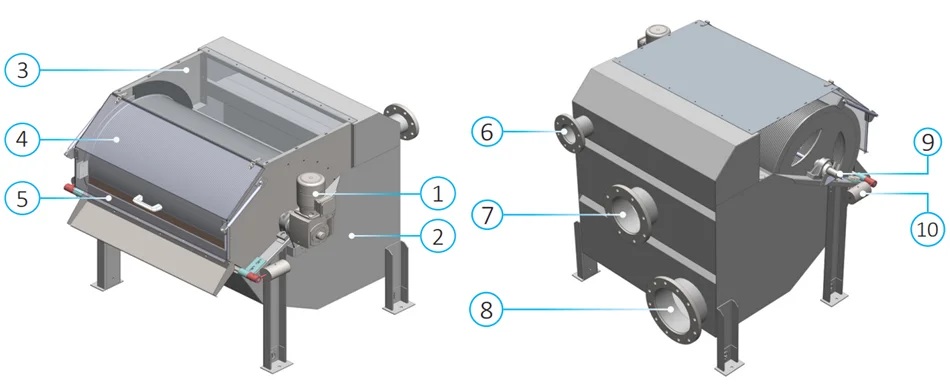

Externally-fed Rotary Drum Screens are individually designed to meet the client’s needs with regard to headbox configuration, inlets/outlets, height, width, pumped or gravity flow, etc.

All externally fed screens are equipped with overflow bypass provisions, located to suit the client’s needs, eliminating overflow concerns.

All stainless steel construction featuring a fully chassis legs, pans, and other extraneous parts with no hidden add-on costs.

The wedge wire screen with variable slot opening provides solids removal based on client’s specific particle size distribution.

Each system is equipped with an integral sump which can be oversized and/or conformed to meet design and potential upset conditions.

Externally fed screens are equipped with high pressure, CIP able spray manifold systems which can be run automatically or with manual operation.

Externally rotary fed drum screen function

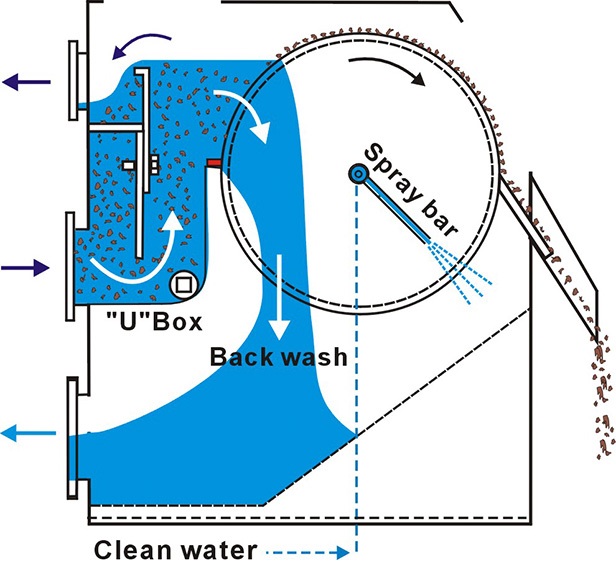

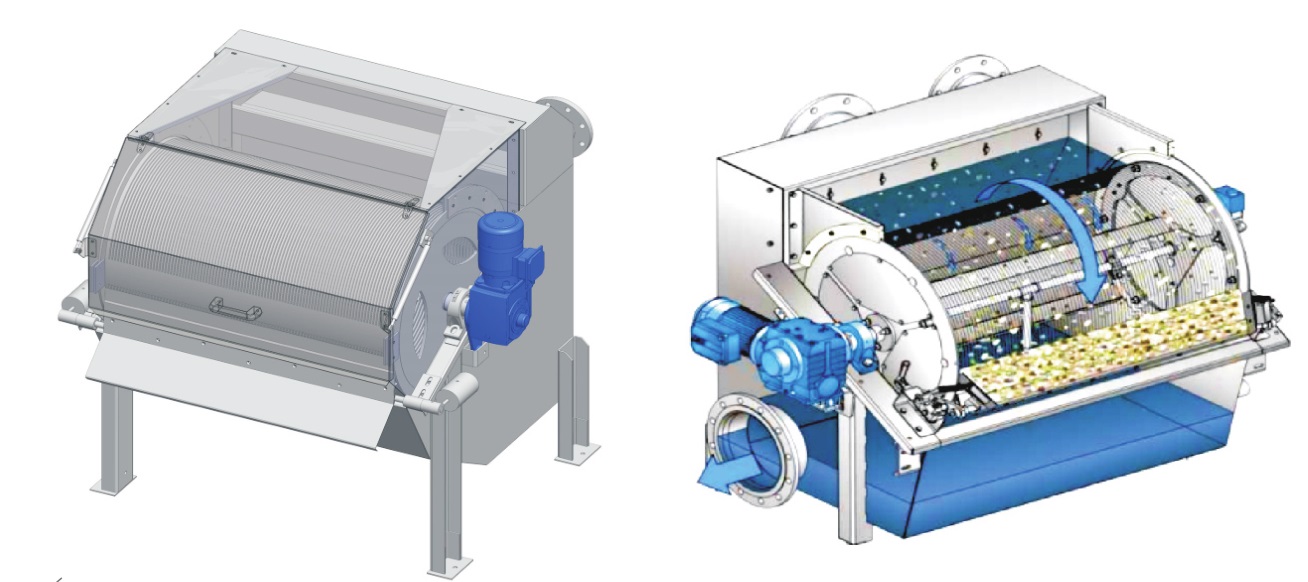

Waste water is conveyed through a distributor onto the external surface of the drum screen.

The side sealing consists of nylon sliding blocks.

Solids are retained on the external surface of the drum screen and subsequently discharged. The drum is cleaned by means of a brass plate.

After passing through the inside of the drum screen, clean water is collected on the bottom of the tank and discharged through a nozzle.

Rotation of the filter occurs by coupling connection to a gear reducer mounted at the end of the drum.

At the opposite end a cleaning system is installed. The system is composed of a pipe equipped with a high pressure nozzle which periodically cleans the filtering drum (mobile washing system). The system has to be connected to the water mains.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. Compact design, easy to install in narrow spaces / aerial channels.

2. High flow rates.

3. Self-cleaning.

4. User-friendly.

5. Low energy consumption and limited maintenance.

Externally rotary fed drum screen feature

1. High efficiency.

2. Different power engine options.

3. Compact and stylish design.

4. Suitable design for different capacities.

5. Mining Industry.

6. Fabricated parts entirely manufactured from 304 L / 316 L SS.

7. Shaftless conveyor screw manufactured from 304 / 316 SS or special high resistance steel.

Externally rotary fed drum screen application

Municipal Wastewater Treatment Plants: Removing fine and coarse solids during primary treatment.

Industrial Wastewater Treatment: Effective screening of processed water in industries like food processing, pulp and paper, chemical manufacturing, and more.

Sludge Thickening: Supporting solid-liquid separation before digestion or dewatering.

Effluent Pre-treatment: Reducing solid load before biological treatment processes.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China