Externally rotary fed drum screen description

This stainless steel wedge wire screen is self-cleaning by nature due to constant back washing.

This often allows for only intermittent use of the spray bar cleaning system, reducing water usage.

Not well suited for fine screening of high flows, but the use of the doctor blade system makes this mechanical screen well suited when oils and grease are present.

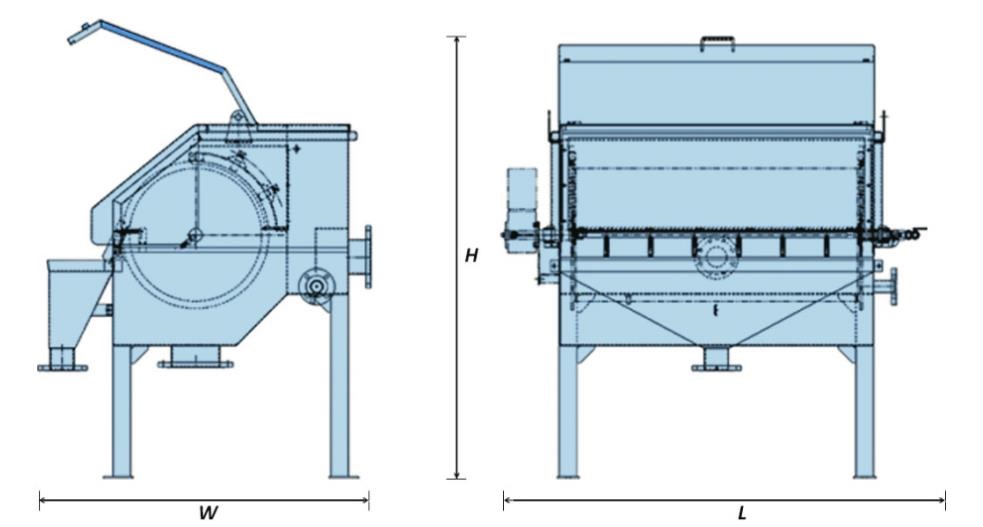

Sized based on peak flow, solids and fats, oils, grease loadings in the wastewater/process water, these units can be configured with a variety of piping scenarios, overall dimensions and slot openings.

Bypass configurations allow for bypass of overflow when upset conditions occur.

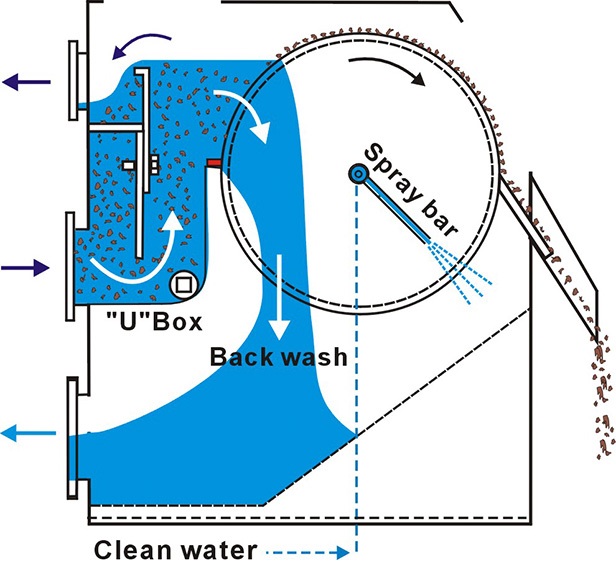

Externally rotary fed drum screen function

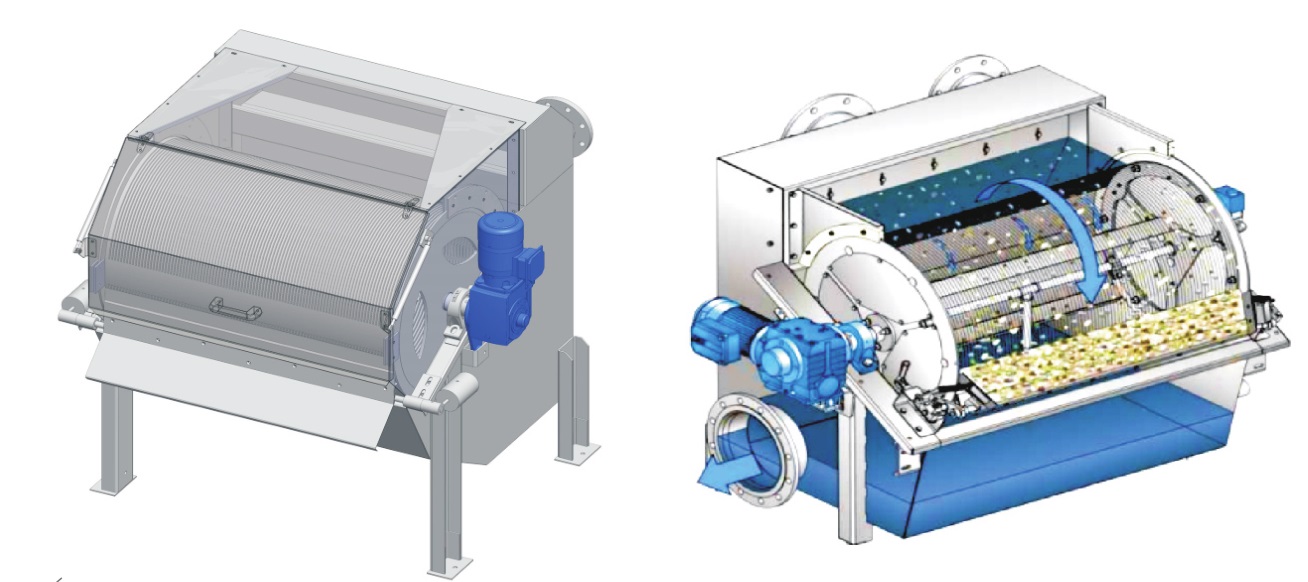

In an externally fed design, wastewater enters a headbox where it is evenly distributed onto the outer surface of the rotating drum.

Solids larger than the screen opening size are trapped and gradually conveyed by the drum rotation to a discharge point.

Fine particles are efficiently captured, while the liquid filtrate passes through the screen and continues in the treatment process.

Some models also feature a spray bar system for automatic cleaning, maintaining peak filtration performance over extended periods.

Externally rotary fed drum screen model

| Industry Type | Slot (mm) | RDS03/300 | RDS06/400 | RDS06/700 | RDS06/1000 | RDS06/1300 | RDS06/1600 | RDS08/2000 | RDS08/2500 |

|---|---|---|---|---|---|---|---|---|---|

| Paper Industry | 0.5 | 6 | 20 | 40 | 60 | 80 | 100 | 130 | 190 |

| Slaughter House | 0.5 | 4 | 15 | 30 | 45 | 60 | 75 | 95 | 130 |

| Seafood Industry | 0.75 | 5 | 17 | 35 | 50 | 70 | 90 | 110 | 140 |

| Meat Industry | 0.75 | 6 | 20.5 | 40 | 60 | 80 | 100 | 130 | 190 |

| Meat Industry | 1.0 | 7.5 | 25 | 50 | 75 | 100 | 125 | 150 | 220 |

| Vegetable Industry | 1.0 | 12 | 40 | 75 | 110 | 150 | 180 | 220 | 330 |

Externally rotary fed drum screen advantage

1. High Efficiency: With an optimized screening surface, these rotary drum screens for wastewater treatment deliver superior removal of fine particles, protecting pumps, membranes, and other critical equipment.

2. Low Maintenance: Robust design and automatic self-cleaning features, such as integrated spray bars, and maintenance of rotary drum screens is simple and infrequent.

3. Stainless Steel Construction: The stainless steel rotary drum screens resist corrosion and offer long service life, even in harsh environments.

4. Energy Savings: Designed for continuous operation with minimal energy consumption, making them a smart choice for environmentally conscious operations.

5. Versatility: Suitable for municipal, industrial, and sludge treatment applications, including primary wastewater treatment and pretreatment screening systems.

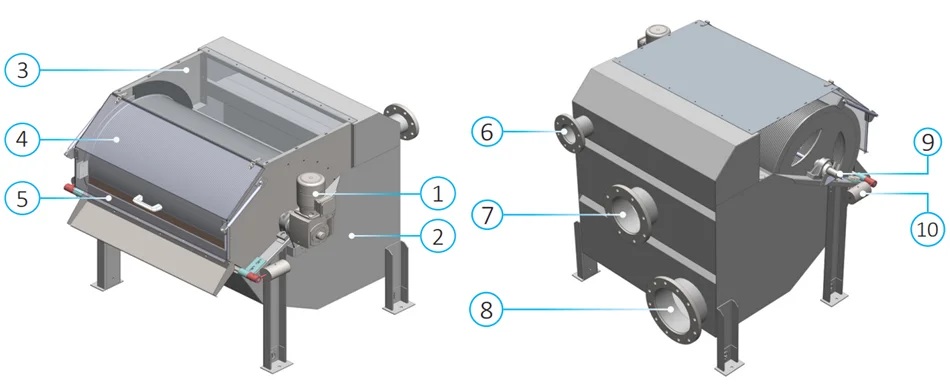

Externally rotary fed drum screen feature

1. Feed chamber with incorporated overflow.

2. Designed to allow sewage to cover the entire width of the cylinder.

3. Spillway blade made of wear-resistant material that exerts constant pressure on the cylinder.

4. Backwash by means of a device installed in the screening cylinder.

5. Spacing between 0.25 and 6 mm wedge wire or from 1 to 6 mm perforated.

6. Worm geared motor and helical gears.

Externally rotary fed drum screen application

Civil purification plants

Process of Water separation

Treatment of Industrial waste water such as;

1. Paper Mills

2. Food Industry

3. Chemical Industry

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China