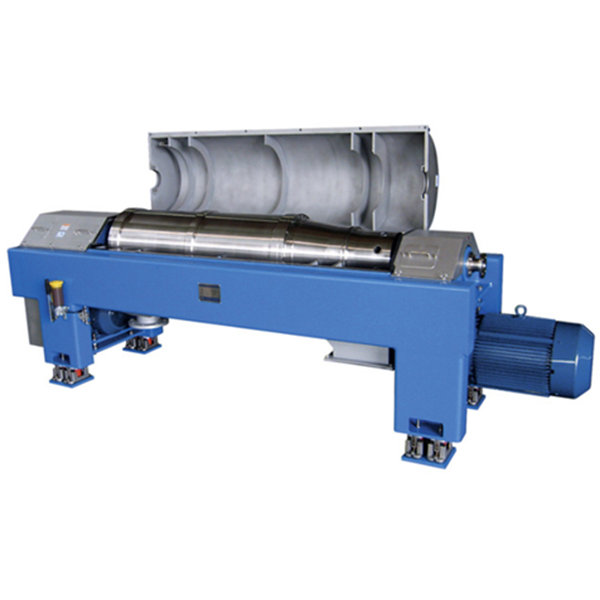

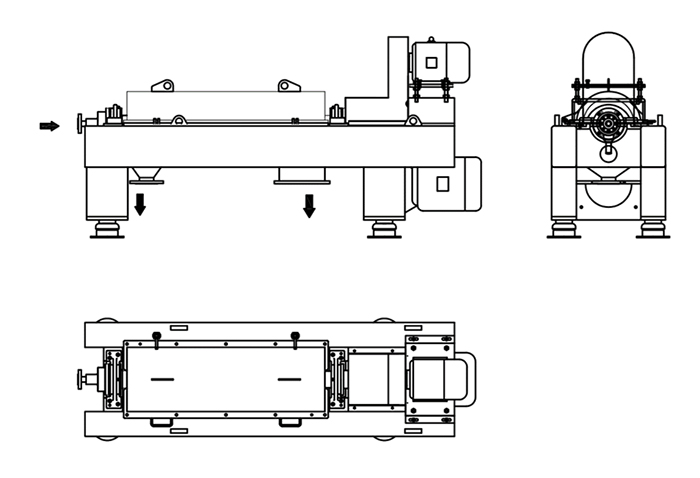

3 Phase Decanter Centrifuges Description

The decanter’s hour has come as soon as the solids content in the suspension to be processed is particularly high. These machines provide the benefits of high clarifying efficiency and maximum dewatering as well as the separation of liquids with the simultaneous removal of solids. The main requirements in this respect include a high bowl speed, a powerful drive for the scroll and a scroll speed which automatically adapts to the solids loading in the feed.

3 Phase Decanter Centrifuges Model

Model

LW250-900

250

900

5000

3500

0.5-3

11/5.5

LW350-1500

350

1500

3800

2850

1-5

18.5/5.5

LW400-1200

400

1200

3400

2581

1-8

22/7.5

LW400-1600

400

1600

3400

2581

2-10

22/7.5

LW400-1800

400

1800

3400

2581

2-12

22/7.5

LW450-1800

450

1800

3200

2572

5-20

30/7.5

LW450-2000

450

2000

3200

2572

5-25

30/7.5

LW530-2280

530

2280

2800

2350

10-50

45/15

LW600-2400

600

2400

2600

2265

15-65

55/18.5

LW650-2600

650

2600

2400

2100

20-80

55/90

LW720-2500

720

2500

2200

1950

25-90

75/90

LW800-2560

800

2560

2000

1800

30-100

90/132

LW800-3200

800

3200

2000

1800

30-110

90/132

LW900-3200

800

3200

1800

1650

30-150

132/200

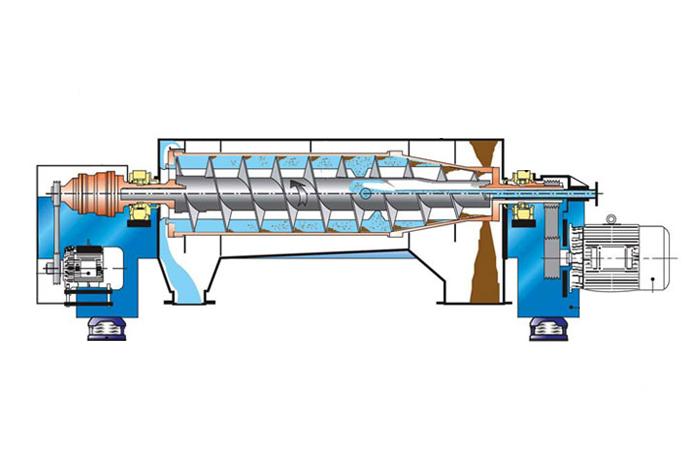

3 Phase Decanter Centrifuges Principle

A decanter centrifuge separates solids from one or two liquid phases in one single continuous process. This is done using centrifugal forces that can be well beyond 3000 times greater than gravity. When subject to such forces, the denser solid particles are pressed outwards against the rotating bowl wall, while the less dense liquid phase forms a concentric inner layer. Different dam plates are used to vary the depth of the liquid – the so-called pond – as required.

The sediment formed by the solid particles is continuously removed by the screw conveyor, which rotates at a different speed than the bowl. As a result, the solids are gradually “ploughed” out of the pond and up the conical “beach”. The centrifugal force compacts the solids and expels the surplus liquid. The dried solids then discharge from the bowl. The clarified liquid phase or phases overflow the dam plates situated at the opposite end of the bowl.

3 Phase Decanter Centrifuges Advantages

Higher Processing Capacity

Modern decanter centrifuges process impressive volumes in compact footprints:

Small units handle 1-5 m³/hour

Medium-sized units process 5-50 m³/hour

Large industrial units can exceed 100 m³/hour

This throughput dwarfs what’s possible with traditional settling or filtration systems of comparable size.

Superior Separation Efficiency

With G-forces exceeding 3,000 times gravity, decanter centrifuges capture particles as small as 2-5 microns – performance impossible with conventional separation methods. This efficiency translates to:

Clearer liquid phases

Drier solid phases

Higher recovery rates of valuable materials

Continuous Operation Capability

Unlike batch processing technologies, decanter centrifuges operate continuously with minimal interruptions:

24/7 operation potential

Reduced labor requirements

Consistent product quality

Lower overall operating costs per unit processed

Smaller Footprint

A decanter centrifuge processing 20 m³/hour might occupy just 10-15 square meters of floor space – a fraction of what settling tanks or filter presses would require for equivalent capacity. This space efficiency proves particularly valuable in:

Offshore platforms

Urban treatment facilities

Retrofit installations with limited space

Automation and Process Control

Modern decanter centrifuges feature sophisticated control systems that deliver:

Automated operation adjustments based on feed variations

Remote monitoring and operation

Precise control over separation parameters

Data collection for process optimization

3 Phase Decanter Centrifuges Application

1. Industrial and municipal wastewater treatment

2. Oil & gas drilling mud/fluid control

3. Washing, separation and dewatering of starch

4. Mycelium and zymotic fluid separation for antibiotic

5. Dewatering of soybean and wheat protein

6. Dewatering of fish power and fish meat

7. Dewatering of vinasse

8. Clarification and extraction of fruit juice

9. Separation and purification for animal and vegetable oil

10. Production and purification of olive oil, palm oil, avocado oil

11. Separation and purification for coal tar

12. Grading of kaolin and graphite

13. Grading and dewatering of dyestuff and pigment

14. Froth flotation for cleaned coal and dewatering of coal mud

15. Grading and dewatering of minerals

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China