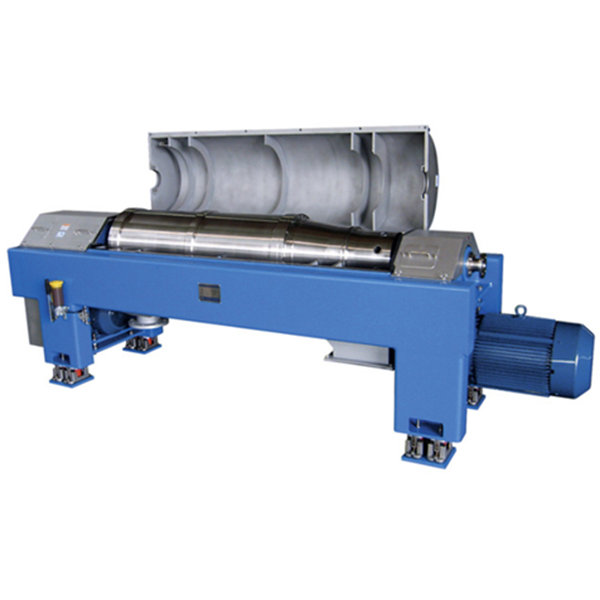

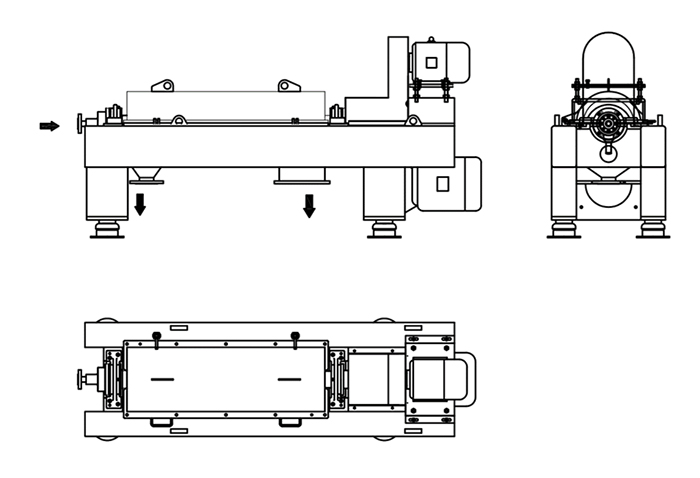

Industrial Decanter Centrifuge System Description

Clarifying decanters are used to separate solids out of a suspension to obtain a virtually solids-free, clarified liquid. Dewatering decanters ensure maximum concentration of the solids to get them as dry as possible. Separating decanters separate two chemically immiscible liquids with simultaneous separation of the solids. Classifying decanters split the solids mixture of the suspension into a fine (small particles) and a coarse (large particles) fraction. Extraction decanters mix a liquid containing a solid or extract with a liquid agent which contains the solids or liquid after mixing. Finally, there is the possibility of integrating a co-current, counter-current or dilution washing system in the decanter for washing the suspended solids.

Industrial Decanter Centrifuge System Model

Model

Drum diameter

mm

Length

mm

Maximum speed

rpm

Hightest separation

factor g

Mixture capacity

m3/h

Motor Power

Kw

LW250-900

250

900

5000

3500

0.5-3

11/5.5

LW350-1500

350

1500

3800

2850

1-5

18.5/5.5

LW400-1200

400

1200

3400

2581

1-8

22/7.5

LW400-1600

400

1600

3400

2581

2-10

22/7.5

LW400-1800

400

1800

3400

2581

2-12

22/7.5

LW450-1800

450

1800

3200

2572

5-20

30/7.5

LW450-2000

450

2000

3200

2572

5-25

30/7.5

LW530-2280

530

2280

2800

2350

10-50

45/15

LW600-2400

600

2400

2600

2265

15-65

55/18.5

LW650-2600

650

2600

2400

2100

20-80

55/90

LW720-2500

720

2500

2200

1950

25-90

75/90

LW800-2560

800

2560

2000

1800

30-100

90/132

LW800-3200

800

3200

2000

1800

30-110

90/132

LW900-3200

800

3200

1800

1650

30-150

132/200

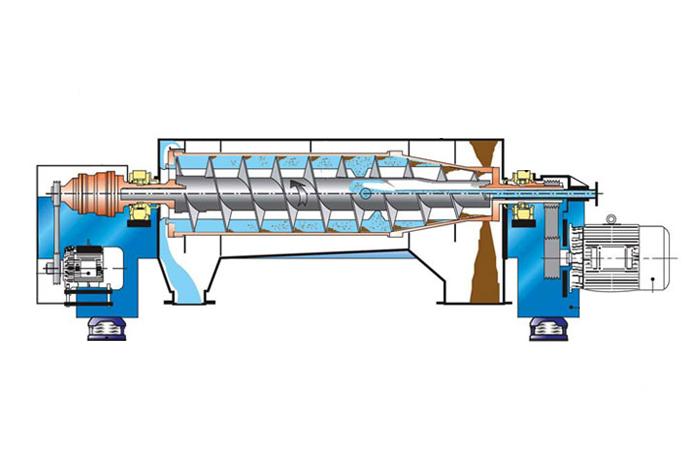

Industrial Decanter Centrifuge System Principle

Decanter Centrifuge is a device that uses centrifugal force to achieve solid-liquid separation. Its core working principle is to separate solids and liquids of different densities into layers in the drum through the centrifugal field generated by high-speed rotation, and discharge them continuously through the screw conveyor to achieve automatic separation.

Industrial Decanter Centrifuge System Advantages

Continuous and automated operation

Traditional separation methods such as filter pressing and natural sedimentation require intermittent operation, while decanter centrifuge can achieve continuous and uninterrupted operation, greatly improving production efficiency.

Industrial Decanter Centrifuge System Application

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China