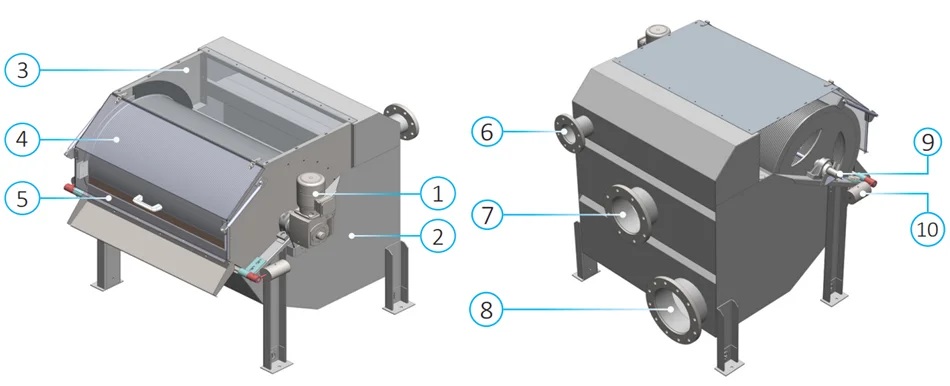

Externally-fed Rotary Drum Screens Description

Externally-fed Rotary Drum Screens are individually designed to meet the client’s needs with regard to headbox configuration, inlets/outlets, height, width, pumped or gravity flow, etc.

All externally fed screens are equipped with overflow bypass provisions, located to suit the client’s needs, eliminating overflow concerns.

All stainless steel construction featuring a fully chassis legs, pans, and other extraneous parts with no hidden add-on costs.

The wedge wire screen with variable slot opening provides solids removal based on client’s specific particle size distribution.

Each system is equipped with an integral sump which can be oversized and/or conformed to meet design and potential upset conditions.

Externally fed screens are equipped with high pressure, CIPable spray manifold systems which can be run automatically or with manual operation.

Externally-fed Rotary Drum Screens Function

Waste water is conveyed through a distributor onto the external surface of the drum screen. The side sealing consists of nylon sliding blocks.

Solids are retained on the external surface of the drum screen and subsequently discharged. The drum is cleaned by means of a brass plate.

After passing through the inside of the drum screen, clean water is collected on the bottom of the tank and discharged through a nozzle.

Rotation of the filter occurs by coupling connection to a gear reducer mounted at the end of the drum.

At the opposite end a cleaning system is installed. The system is composed of a pipe equipped with a high pressure nozzle which periodically cleans the filtering drum (mobile washing system). The system has to be connected to the water mains.

Externally-fed Rotary Drum Screens Advavtage

Externally-fed Rotary Drum Screens Feature

Externally-fed Rotary Drum Screens Application

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China