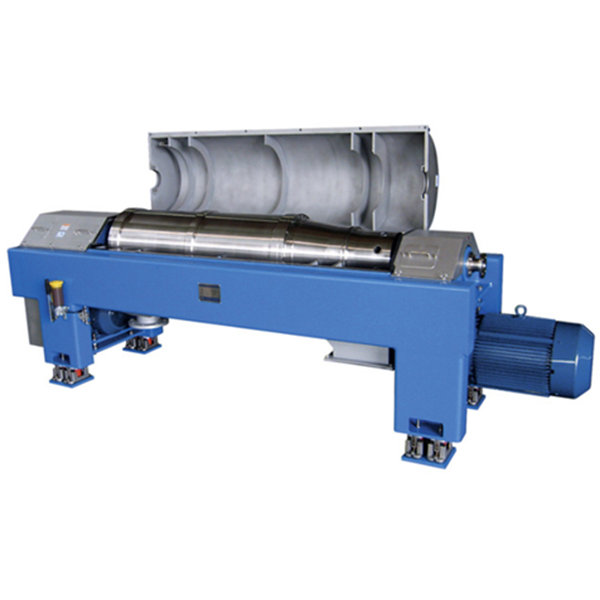

2 Phase Decanter Centrifuges Description

2 Phase Decanter Centrifuges are also known as decanter centrifuges, centrifugal decanters or simply decanter machines and are primarily used for separation of liquids from appreciable amounts of solids. Decanters can separate over 50% (v/v) solids from liquids on a continuous basis. Typical industrial decanter applications include Crude Oil Tank Bottoms; Waste Oil; Industrial Wastewater; Sludge Dewatering; Fish Meal; WVO/UVO De-Sludging; Paint Sludge; Rendering etc. etc. For More Information on Decanter Centrifuge Repair Call Centrifuge World.

2 Phase Decanter Centrifuges Model

Model

LW250-900

250

900

5000

3500

0.5-3

11/5.5

LW350-1500

350

1500

3800

2850

1-5

18.5/5.5

LW400-1200

400

1200

3400

2581

1-8

22/7.5

LW400-1600

400

1600

3400

2581

2-10

22/7.5

LW400-1800

400

1800

3400

2581

2-12

22/7.5

LW450-1800

450

1800

3200

2572

5-20

30/7.5

LW450-2000

450

2000

3200

2572

5-25

30/7.5

LW530-2280

530

2280

2800

2350

10-50

45/15

LW600-2400

600

2400

2600

2265

15-65

55/18.5

LW650-2600

650

2600

2400

2100

20-80

55/90

LW720-2500

720

2500

2200

1950

25-90

75/90

LW800-2560

800

2560

2000

1800

30-100

90/132

LW800-3200

800

3200

2000

1800

30-110

90/132

LW900-3200

800

3200

1800

1650

30-150

132/200

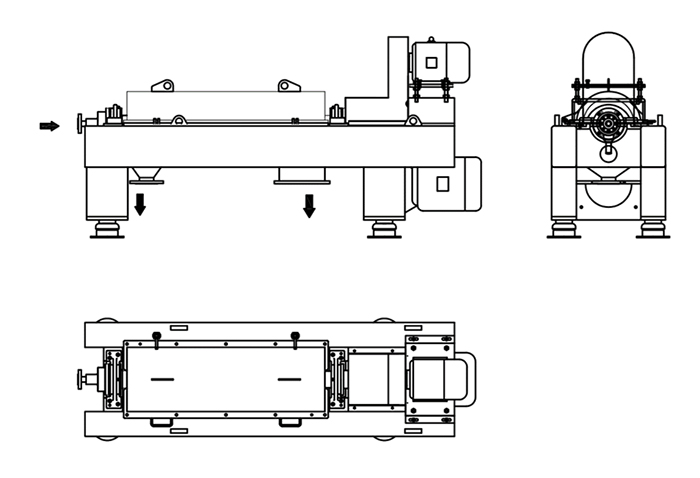

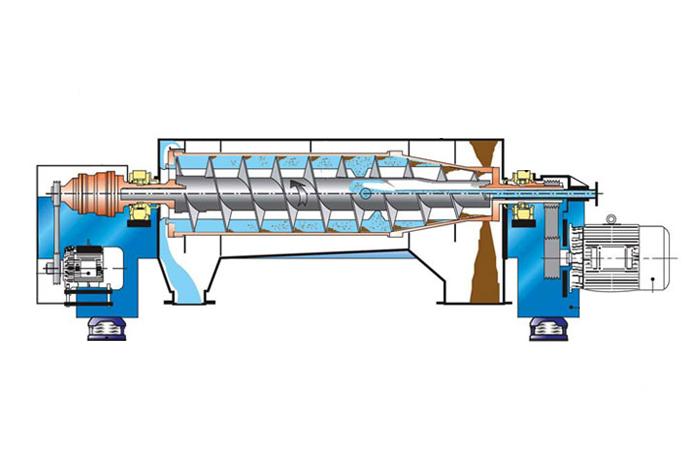

2 Phase Decanter Centrifuges Principle

1: The slurry is brought into the centrifuge through an intake pipe and onto a conveyor.

2: Utilizing an internal feed compartment, the conveyor moves the slurry through a nozzle into the bowl.

3: The bowl rotates at high speeds to induce centrifugal forces.

4: High speed rotation separates the solid material from the liquid in a matter of seconds.

5: The conveyor delivers the solid material upwards where it is discharged through a nozzle.

6: The solid material removed, the purified liquid is released from a separate output. The ability to purify a liquid makes decanter centrifuges ideal for waste water treatment facilities. However, there are variety of industries for which such centrifuges play an important role. Similar to other decanter equipment, centrifuges are simple to install and do not require a foundation to build upon. Their efficiency saves time and materials and is an essential component for many blue collar industries

2 Phase Decanter Centrifuges Features

The environmental advantages of decanter centrifuges include:

Reduced chemical consumption compared to some separation alternatives

Lower energy usage per unit processed versus thermal drying

Reduced waste volumes requiring disposal

Water recovery and recycling opportunities

2 Phase Decanter Centrifuges Application

DAGYEE 2 Phase Decanter Centrifuges are available in a range of sizes and capacities to suit a variety of materials in many different applications. They offer high separation of solids and liquids producing a low moisture content solids discharge between that achieved by a Thickener and a Filter Press. The liquid recovered can be recycled back into the process reducing overall demand.

2 Phase Decanter Centrifuges from DAGYEE can be used for solids recovery to capture valuable products from a liquid stream or to reduce the volume of material reporting to settling ponds, reducing the size requirements for the ponds or eliminating the need for them altogether. In this regard, DAGYEE Decanter Centrifuges offer a sustainable solution to pond reduction/elimination and water recovery in areas where water is scarce, or expensive, or space for traditional settling lagoons is not available or at a premium. This may also help with environmental permitting and regulations.

DAGYEE 2 Phase Decanter Centrifuges are compact, easy to operate and have a small footprint. They offer long service life with minimal maintenance requirements.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China