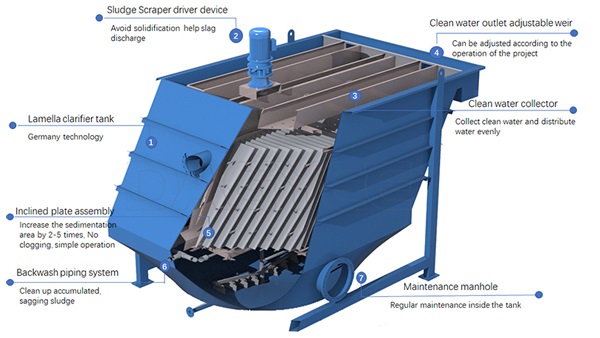

A Lamella Clarifier is a type of sedimentation tank that uses a series of inclined plates to separate solid particles from liquid. These plates, also known as lamella plates, are arranged at an angle to increase the effective settling area while reducing the footprint of the tank. The inclined plates create a flow pattern that allows solids to settle on the plates’ surface and slide down to the bottom of the tank. The clarified liquid exits the tank through a collection system located at the top of the unit.

The DAGYEE clarifier uses the time proven concept of inclined plate clarification. This type of clarifier uses gravity in conjunction with the projected settling area of the 60-degree angle plastic parallel plates to settle solids from the pre-treated liquid flow. This treated liquid flows first to the flocculation tank where a polymer is added to promote floc growth, then down to the bottom of the clarifier and up through the plate pack(s) while the solids settle out to the bottom sludge cone or cones – depending upon the size. The solids are intermittently taken from the bottom cone tank for a further settling of the solids and then, finally to a filter press for final dewatering.

Lamella clarifier available options

• Flash mixing/flocculation tank with agitator

• Full glass steel or stainless steel structure

• Concrete tank design

• Special coatings and plates

• Integrated mechanical sludge thickener

• Overhaul platforms and ladders

• In-house laboratory analysis to optimize equipment

• Drinking water design

• Gasket and removable cover

• Automatic desilting

• Instrumentation and control

• Chemical feed equipment

• Sludge treatment and dewatering

• Pilot size units for field testing

Lamella clarifier model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

| DLC Model | Capacities (m³/h) | Piping Connections (mm) | Physical Dimensions (m) | |||||

|---|---|---|---|---|---|---|---|---|

| Inlet(a) | Effluent(b) | Sludge(c) | Backwash(d) | L | W | H | ||

| DLC 5 | 5 | 80 | 80 | 50 | 50 | 2.55 | 1.6 | 2.9 |

| DLC 10 | 10 | 100 | 100 | 50 | 50 | 3.35 | 1.82 | 3 |

| DLC 15 | 15 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 20 | 20 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 30 | 30 | 150 | 150 | 50 | 50 | 4.2 | 2.22 | 3 |

| DLC 40 | 40 | 150 | 150 | 50 | 50 | 4 | 2.8 | 3 |

| DLC 50 | 50 | 200 | 200 | 50 | 50 | 4.65 | 2.82 | 3 |

| DLC 60 | 60 | 200 | 200 | 50 | 50 | 4.7 | 3 | 3 |

| DLC 70 | 70 | 250 | 200 | 50 | 50 | 6.4 | 2.6 | 3 |

| DLC 80 | 80 | 250 | 200 | 50 | 50 | 6.8 | 2.82 | 3 |

| DLC 100 | 100 | 250 | 250 | 50 | 50 | 7.05 | 3.02 | 3 |

Significantly reduced footprint: The Lamella System’s design reduces its footprint by up to 90% compared to conventional clarifiers, making it an ideal choice for space-constrained areas.

Operational Economy: Known for its low maintenance requirements, the Lamella Clarifier / Settler also eliminates the need for replacement parts, ensuring cost-effective operation over time.

Modular Design: The modular nature of the system facilitates easy expansion, allowing for scalability and adaptability to changing processing requirements.

Cost Efficiency: On a total installed basis, the Lamella Clarifier / Settler proves to be more cost-effective than traditional options, providing economic benefits from installation to operation.

Our Lamella Clarifier / Settler is the space efficient settling solution for water and wastewater treatment, including reuse of process and backwash water.

Our system is a complete modular solution that includes a flocculation tank, mixers and a sludge scraper. This comprehensive package ensures a seamless, integrated process from start to finish. The modular design allows for easy installation and adaptability to different requirements, making it a versatile choice for many applications.

Our Lamella settler is commonly used in potable water and sewage treatment works, as well as the pulp and paper, chemical process, food processing, surface treatment, power, mining & minerals, iron and steel industries.

Lamella clarifier application

Lamella clarifiers are used in various sectors such as municipal wastewater treatment, food processing, aquaculture, chemical industries, metallurgy, and quarries and sand pits. They are particularly appreciated when large volumes of water need to be treated with high efficiency and limited footprint.

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China