The implementation of lamella clarifiers in wastewater treatment is widely recognized due to their numerous advantages, such as their ability to handle high flow rates and their versatility across various industries. They are an essential element in the treatment process, appearing in sectors like municipal sewage treatment, industrial effluent processing, and water recycling. Proper installation and maintenance of lamella clarifiers are crucial for their optimal performance and compliance with environmental regulations. Recent technological advancements have further improved the efficacy of these systems, making them more sustainable and cost-effective solutions for wastewater management.

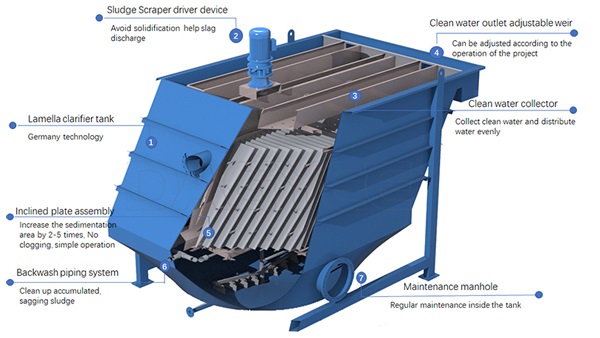

The lamella clarifier consists of 3 mm thick anti-clogging plates to facilitate water flow. Suspended particles are retained on the surface of the plates and accumulate as water circulates.

Its operation is based on the difference in density between suspended particles and water. Centrifugal pressure pushes lighter particles towards the surface, while heavier ones remain in suspension.

When suspended particles gather around the surface of the blades, a quick-drain system evacuates them.

Lamella clarifier available options

• Flash mixing/flocculation tank with agitator

• Full glass steel or stainless steel structure

• Concrete tank design

• Special coatings and plates

• Integrated mechanical sludge thickener

• Overhaul platforms and ladders

• In-house laboratory analysis to optimize equipment

• Drinking water design

• Gasket and removable cover

• Automatic desilting

• Instrumentation and control

• Chemical feed equipment

• Sludge treatment and dewatering

• Pilot size units for field testing

Lamella clarifier model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

| DLC Model | Capacities (m³/h) | Piping Connections (mm) | Physical Dimensions (m) | |||||

|---|---|---|---|---|---|---|---|---|

| Inlet(a) | Effluent(b) | Sludge(c) | Backwash(d) | L | W | H | ||

| DLC 5 | 5 | 80 | 80 | 50 | 50 | 2.55 | 1.6 | 2.9 |

| DLC 10 | 10 | 100 | 100 | 50 | 50 | 3.35 | 1.82 | 3 |

| DLC 15 | 15 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 20 | 20 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 30 | 30 | 150 | 150 | 50 | 50 | 4.2 | 2.22 | 3 |

| DLC 40 | 40 | 150 | 150 | 50 | 50 | 4 | 2.8 | 3 |

| DLC 50 | 50 | 200 | 200 | 50 | 50 | 4.65 | 2.82 | 3 |

| DLC 60 | 60 | 200 | 200 | 50 | 50 | 4.7 | 3 | 3 |

| DLC 70 | 70 | 250 | 200 | 50 | 50 | 6.4 | 2.6 | 3 |

| DLC 80 | 80 | 250 | 200 | 50 | 50 | 6.8 | 2.82 | 3 |

| DLC 100 | 100 | 250 | 250 | 50 | 50 | 7.05 | 3.02 | 3 |

The lamellar decanter provides a better sludge index by effectively separating suspended particles. The inclined plates facilitate slow water flow. Each suspended particle has enough time to accumulate on the surface.

Moreover, lamella clarifiers provide a lower Hazen speed than other types of clarifiers. This Hazen velocity is an indicator of the quality of clarified water, and the lower it is, the clearer the water. It is measured by the sludge index.

Another benefit of a lamella clarifier is its simplicity of use and maintenance. The lamellae can easily be cleaned and the sludge is removed by a draining system.

First of all, a lamella clarifier is generally more expensive than a conventional clarifier. This is because of the lamellae inside.

However, since the lamella clarifier is about 10 times more efficient than a conventional clarifier in terms of sludge index and speed, this is not a decisive argument.

Another issue is the necessity to clean the lamellae. The thin lamellae (less than 2 mm) can collapse under the weight of the sludge, so it is necessary to clean them often. The clarifiers with the automatic lamellae cleaning option are more convenient and do not have this problem.

Lamella clarifier application

Lamella clarifiers are used in various sectors such as municipal wastewater treatment, food processing, aquaculture, chemical industries, metallurgy, and quarries and sand pits. They are particularly appreciated when large volumes of water need to be treated with high efficiency and limited footprint.

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China