Static Mixers

DAGYEE offers a range of static mixers for continuous mixing of fluids within a pipeline. Learn about the benefits, types, and applications of DAGYEE static mixers with no moving parts, low cost, and quick delivery.

Static Mixer Structure

The simple yet highly effective design of static mixers belies their advanced capabilities for continuous mixing, blending, and homogenizing of liquids and gases in industrial process applications. Although most static mixers are manufactured from heavy, sturdy metals designed to withstand high pressure and aggressive chemicals, specialized varieties utilize chemical-resistant plastics, such as polypropylene and polyvinylidene fluoride (PVDF), for less demanding or highly corrosive environments. The main components of these industrial mixing devices—the tube (mixer housing) and internal mixing elements—are manufactured from an assortment of materials including high-quality engineered plastics, 316 stainless steel, as well as more advanced materials like glass-lined steel and exotic alloys to ensure compatibility with critical manufacturing processes in petrochemical, food and beverage, water treatment, and pharmaceutical industries.

Housing

The housing for a static mixer serves as the pressure vessel that encases the mixing elements and is crucial for ensuring process safety and performance. Static mixer housings can be fabricated from a range of materials—including metals like stainless steel (304, 316), high-strength aluminum alloys, hastelloy, titanium, as well as thermoplastics such as PVC, CPVC, polyethylene, or specialty fluoropolymers like Teflon (PTFE). The choice of housing material is dictated by several factors: the type of fluids (acids, caustics, high viscosity liquids), operating temperature, process pressure, and industry-specific sanitary regulations. For instance, the chemical processing and water treatment sectors often specify high chemical resistance, while the food and beverage industry demands materials that are hygienic and easy to sanitize, favoring stainless steel for its non-porous, corrosion-resistant surface.

The cylindrical configuration of most static mixer housings is designed to seamlessly integrate into existing pipework or custom inline mixing systems, minimizing pressure drop and ensuring laminar-to-turbulent flow transition as appropriate. Static mixers are commonly installed in-line within process piping, allowing for efficient continuous mixing of fluids in motion without needing external power or moving parts. Features such as flanged ends, threaded connections, or tri-clamp fittings can be specified based on installation requirements. Engineering the housing to exact tolerances is a key part of process equipment design, as factors like flow rate, viscosity, and compatibility must be considered early in the manufacturing process to guarantee maximum mixing efficiency and performance consistency.

Mixing Elements

The heart of every static mixer lies in its mixing elements—engineered components arranged within the housing to optimize flow dynamics, maximize surface renewal, and induce radial and axial mixing. These elements are custom-made from a wide variety of materials, including chemical-resistant plastics (like PTFE and PVDF), various stainless steels, titanium, and specialty alloys. Selection depends on process compatibility, abrasive wear, fluid toxicity, temperature, and pressure. Static mixer elements can take several forms, including helical blades, baffles, channels, fins, and more, each optimized to achieve a specific type of mixing, dispersion, or emulsification. Advanced CFD (computational fluid dynamics) modeling is often used in the design phase to validate and optimize performance for specialized applications such as polymer blending, gas-liquid mass transfer, and high-viscosity fluid processing.

Blades – Blade mixing elements are engineered in various shapes—such as helical, twisted, or spiral—and are precisely positioned to split and redirect the process flow, generating turbulence and maximizing mixing intensity. The specific shape, pitch, and orientation of blades are critical factors in determining how quickly and completely the fluids are homogenized. High-performance blade mixers are essential in processes that require rapid and thorough blending of fluids of different viscosities or concentrations, such as in adhesives, coatings, or chemical dosing.

Channels – Channel mixing elements are characterized by rectangular, square, or custom-profiled cross-sections that generate varied velocity profiles and controlled shearing forces within the mixer. By ensuring even distribution of process fluids, channel mixers minimize energy loss, making them ideal for chemical dosing, polymerization, and precise pH adjustment. Their open architecture is beneficial for systems prone to fouling or those requiring low pressure drop, such as in municipal water treatment and liquid fertilizer blending.

Helical – Helical static mixers are designed with alternating elements set at 90° angles, causing a constant inversion and rotation of the fluid stream. This progressive movement effectively eliminates dead zones and ensures comprehensive blending. Helical mixers are frequently available as removable cartridges for easy cleaning, with options for jacketed or heated configurations to handle temperature-sensitive processes—common in pharmaceutical, cosmetic, or food-grade applications. Their high mixing performance makes them the go-to choice for inline static mixing tasks that demand superior homogenization and low maintenance.

Fin – Fin-type static mixers utilize strategically placed, curved fins to promote intensive mixing of gases or low-viscosity fluids, generating secondary flow patterns and additional vortices that accelerate homogenization. Designs often incorporate multiple, staggered sets of fins, amplifying their ability to quickly and efficiently blend immiscible fluids or disperse gases, a key feature in applications such as aeration, chemical injection, and polymer blending.

The configuration and type of static mixing elements used in a mixer are tailored to each application, ensuring optimal dispersion, emulsification, or reaction enhancement—whether blending chemical additives, homogenizing slurries, or achieving uniform heat transfer in process fluids. Many leading static mixer manufacturers offer custom design and engineering services, leveraging years of process expertise and simulation capabilities to resolve challenging mixing applications, reduce downtime, and improve production efficiency.

For those evaluating static mixers for purchase, it is essential to consider: the chemical and physical properties of fluids, operational environment (temperature, pressure), required mixing intensity, ease of maintenance (including CIP—clean-in-place—capability), pressure drop limitations, and regulatory requirements for your specific industry. Consulting with an experienced static mixer supplier can lead to significant improvements in process control, reduced operational costs, and enhanced product quality. As modern processing demands increase, innovative static mixer technology continues to evolve, helping industries achieve better mixing, safer operations, and more sustainable outcomes.

Baffles – Baffle elements consist of plates or flat sheets, arranged either diagonally or in a crisscross pattern, creating flow division and recombination that enhance radial and axial mixing. Commonly manufactured from twisted metals, corrugated sheets, or parallel rods, baffles are highly effective for blending miscible liquids with similar viscosities (e.g., water and solvents), as well as maintaining uniformity in suspensions. This design is utilized in industries such as wastewater treatment and chemical manufacturing, where consistent and repeatable mixing is required for high-quality end products.

Static Mixer SK Series Model

|

Model |

Dg(mm) |

dh(mm) |

Q(m3/h) |

|

SK-5/10 |

10 |

5 |

0.15-0.3 |

|

SK-7.5/15 |

15 |

7.5 |

0.3-0.6 |

|

SK-10/20 |

20 |

10 |

0.6-1.2 |

|

SK-12.5/25 |

25 |

12.5 |

0.9-1.8 |

|

SK-16/32 |

32 |

16 |

1.4-3.2 |

|

SK-20/40 |

40 |

20 |

2.2-4.5 |

|

SK-25/50 |

50 |

25 |

3.5-7.0 |

|

SK-32.5/65 |

65 |

32.5 |

5.9-12 |

|

SK-40/80 |

80 |

40 |

9-18 |

|

SK-50/100 |

100 |

100 |

14-28 |

|

SK-62.5/125 |

125 |

125 |

22-44 |

|

SK-75/150 |

150 |

150 |

31-64 |

|

SK-100/200 |

200 |

200 |

56-110 |

|

SK-125/250 |

250 |

250 |

88-177 |

|

SK-150/300 |

300 |

300 |

127-255 |

|

SK-175/350 |

350 |

350 |

173-346 |

|

SK-200/400 |

400 |

400 |

226-452 |

|

SK-250/500 |

500 |

500 |

353-706 |

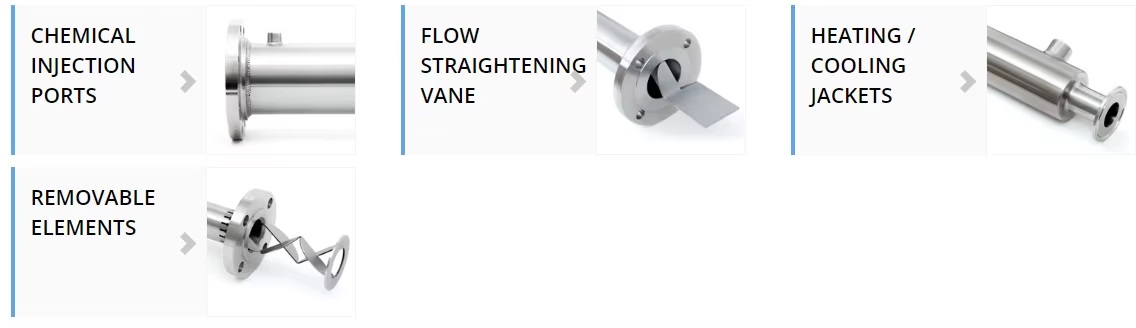

Static Mixer Options

Static Mixer Benefits

Maintenance-Free

DAGYEE Static Mixers are built to last using industrial grade materials specifically tailored to your application.

Low Energy Requirements

Because static mixers are motionless by design, all the energy required to provide a perfect blend is provided by the energy of the flow stream.

Custom-Designed for Your Application

All DAGYEE Static mixers can be custom-tailored to fit your requirements.

Low-Cost

DAGYEE Static Mixers are a low-cost alternative to traditional tank mixers both at purchase and during the mixer's lifetime. There are no running costs associated with operating a DAGYEE Static Mixer on top of running your existing pipeline.

No Moving Parts

Unlike traditional mixers, static mixers remain motionless during the mixing process.

Quick Delivery

DAGYEE maintains complete control over its production process. All static mixers are built in-house at DAGYEE's manufacturing facility outside Chicago and can be manufactured to meet your project schedule.

Static Mixer Applications

A common application is mixing nozzles for two-component adhesives (e.g., epoxy) and sealants (see Resin casting). Other applications include wastewater treatment, flow chemistry and chemical processing. Static mixers can be used in the refinery and oil and gas markets as well, for example in bitumen processing or for desalting crude oil. In polymer production, static mixers can be used to facilitate polymerization reactions or for the admixing of liquid additives.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China