Cartridge Filter Housing Description

Cartridge filter housings are critical components ensuring efficient and effective filtration. DAGYEE manufactures a broad line of both ASME code vertical and horizontal cartridge housings with standard flow rates of up to 8,000 GPM. Housings are built to meet project specifications. DAGYEE is the custom manufacturer of cartridge filter housings for industrial filtration needs.

Cartridge Filter Housing Function

Unfiltered Fluid Entry

The unfiltered fluid (liquid or gas) enters the inlet port of the housing.

Filtration

The fluid is forced from the outside of the filter cartridge to its core. During this passage, the cartridge's membrane or media traps suspended solids, particles, sediments, bacteria, or other contaminants.

Purified Fluid Exit

The now-cleaned fluid exits through the outlet port and continues into the system.

Contaminant Retention

All captured contaminants remain on the exterior or within the matrix of the filter cartridge, which can be replaced easily when it becomes saturated.

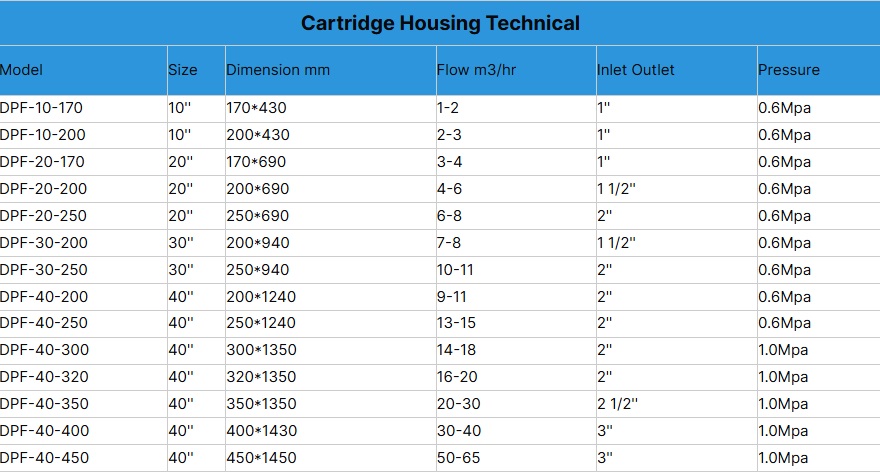

Cartridge Filter Housing Parameter

Cartridge Filter Housing Advantage

High-Efficiency Processing, Ensures Production

Capable of handling high-flow conditions that single-cartridge housings cannot meet, directly supporting main production lines and boosting overall capacity.

Extended Service Cycles, Reduces Costs

The high dirt-holding capacity significantly extends intervals between cartridge changes, reducing consumable costs and maintenance labor expenses.

System Redundancy, Ensures Operational Reliability

Even if one or several cartridges become clogged or damaged, the remaining cartridges continue to operate, providing a buffer for scheduled maintenance and effectively preventing unplanned downtime.

Compact Structure, Saves Space

Compared to connecting multiple single-cartridge housings in parallel, one multi-cartridge housing saves installation space, piping, and valves, resulting in a simpler system and lower overall costs.

Simplified Maintenance, Boosts Efficiency

Replacing all cartridges simultaneously by opening a single top cover minimizes both maintenance time and associated production downtime.

Cartridge Filter Housing Characteristics

Contaminant Removal

To effectively remove unwanted particles, sediments, rust, microorganisms, and other impurities from fluids.

System Protection

To protect sensitive downstream equipment (e.g., pumps, valves, nozzles, instruments) from damage and wear caused by particulates.

Product Quality Assurance

To ensure the final product's purity, clarity, and safety in processes like food and beverage production, pharmaceutical manufacturing, and chemical processing.

Process Efficiency

To maintain consistent flow rates and pressure, preventing clogging and downtime in critical systems.

Cartridge Filter Housing Application

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China