Product description

Industrial Filtration Housings

Also known as filter vessels, housings encase filter bags and cartridges. DAGYEE heavy-duty housings are available in various sizes, materials of construction and custom features for high-level filtration. An ideal choice for stand-alone, manifold or duplex filter systems.

Product function

Housing Body: The housing body is the main structure that encloses the filter cartridges. It is typically made from materials such as stainless steel, carbon steel, or durable plastics to withstand high pressures and corrosive environments.

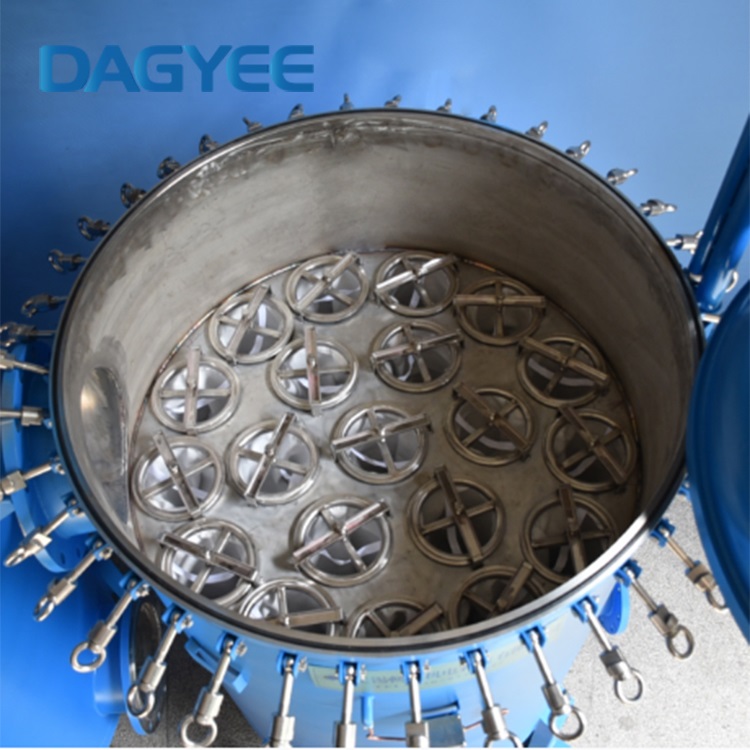

Filter Cartridges: The filter cartridges are the primary filtration elements, available in various materials such as pleated polypropylene, cellulose, or activated carbon. The choice of cartridge depends on the specific application and the type of contaminants to be removed.

Inlet and Outlet Ports: These ports allow fluid to enter and exit the housing. They are designed to accommodate various pipe sizes and connection types, ensuring compatibility with different systems.

Closure Mechanism: The closure mechanism secures the housing body and ensures a tight seal to prevent leaks. It can include clamps, bolts, or swing bolts, depending on the design.

Gaskets and Seals: Gaskets and seals are used to ensure a leak-proof connection between the housing body and the closure mechanism. They are typically made from materials such as silicone, EPDM, or Viton.

Pressure Gauges: Pressure gauges monitor the differential pressure across the filter cartridges, providing an indication of when the cartridges need to be replaced.

Vent and Drain Ports: Vent and drain ports are used to remove air and accumulated debris from the housing during maintenance and cartridge replacement.

Product technical

Seal type: O-rings and flat gasket

Sealing material: nitrile rubber(chemitum), silicone, fluorine rubber, usually use silicon

Rubber seal Filter interface: the threaded, clamp(hoop), GB, HG, DIN, ANSI

Filtration accuracy: 1μm - 100 μm

Body material: SS304/SS 316

Single filter Cartridges housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Diameter mm |

|---|---|---|---|---|---|---|

| DYG-1-10" | 0.5 M³/H | 6/120 | Ø65*250 | 1/2" | 380 | Ø89 |

| DYG-1-20" | 1 M³/H | 6/120 | Ø65*500 | 3/4" | 630 | Ø89 |

| DYG-1-30" | 1.5 M³/H | 6/120 | Ø65*750 | 1" | 880 | Ø89 |

| DYG-1-40" | 2 M³/H | 6/120 | Ø65*1000 | 1" | 1130 | Ø89 |

Single microporous filter housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet-Quick Connector | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-C1-10" | 0.5 M³/H | 6/120 | Ø68*250 | 1 1/4" | 608 | Ø102 |

| DYG-C1-20" | 1 M³/H | 6/120 | Ø68*500 | 1 1/4" | 850 | Ø102 |

| DYG-C1-30" | 1.5 M³/H | 6/120 | Ø68*750 | 1 1/4" | 1100 | Ø102 |

| DYG-C1-40" | 2 M³/H | 6/120 | Ø68*1000 | 1 1/4" | 1350 | Ø102 |

5 Cartridges filter Housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-5-10" | 2.5 M³/H | 6/150 | Ø65*250 | 3/4" | 550 | Ø219 |

| DYG-5-20" | 5 M³/H | 6/150 | Ø65*500 | 1" | 850 | Ø219 |

| DYG-5-30" | 7.5 M³/H | 6/150 | Ø65*750 | 1 1/2" | 1100 | Ø219 |

| DYG-5-40" | 10 M³/H | 6/150 | Ø65*1000 | 2" | 1390 | Ø219 |

5 Cartridges filter Housings with flange

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-5F-10' | 2.5 M³/H | 0-1.0MPa | Ø65*250 | 3/4" | 550 | Ø219 |

| DYG-5F-20' | 5 M³/H | 0-1.0MPa | Ø65*500 | 1" | 850 | Ø219 |

| DYG-5F-30' | 7.5 M³/H | 0-1.0MPa | Ø65*750 | 1 1/2" | 1100 | Ø219 |

| DYG-5F-40' | 10 M³/H | 0-1.0MPa | Ø65*1000 | 2" | 1390 | Ø219 |

Single bag filter housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-1-1S | 18 M³/H | 12/150 | Ø180*410 | 1 1/2" flange | 1040 | Ø219 |

| DYG-1-2S | 36 M³/H | 12/150 | Ø180*810 | 2" flange | 1300 | Ø219 |

| DYG-1-4S | 10 M³/H | 12/150 | Ø105*380 | 1 1/2" BSP female | 850 | Ø133 |

| DYG-1K-1S | 18 M³/H | 12/150 | Ø180*410 | 1 1/2"flange | 1010 | Ø219 |

Multi Bag Filter Housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-2D-2S | 70 M³/H | 12/150 | Ø180*810 | 2" | 1600 | Ø420 |

| DYG-3D-2S | 100 M³/H | 12/150 | Ø180*810 | 3" | 1800 | Ø506 |

| DYG-4D-2S | 130 M³/H | 12/150 | Ø180*810 | 4" | 1800 | Ø506 |

| DYG-6D-2S | 200 M³/H | 12/150 | Ø180*810 | 4" | 2100 | Ø650 |

| DYG-8D-2S | 250 M³/H | 12/150 | Ø180*810 | 5" | 2100 | Ø710 |

| DYG-12D-2S | 400 M³/H | 12/150 | Ø180*810 | 6" | 2100 | Ø910 |

High-Efficiency Processing, Ensures Production: Capable of handling high-flow conditions that single-cartridge housings cannot meet, directly supporting main production lines and boosting overall capacity.

Extended Service Cycles, Reduces Costs: The high dirt-holding capacity significantly extends intervals between cartridge changes, reducing consumable costs and maintenance labor expenses.

System Redundancy, Ensures Operational Reliability: Even if one or several cartridges become clogged or damaged, the remaining cartridges continue to operate, providing a buffer for scheduled maintenance and effectively preventing unplanned downtime.

Contaminant Removal: To effectively remove unwanted particles, sediments, rust, microorganisms, and other impurities from fluids.

System Protection: To protect sensitive downstream equipment (e.g., pumps, valves, nozzles, instruments) from damage and wear caused by particulates.

Product Quality Assurance: To ensure the final product's purity, clarity, and safety in processes like food and beverage production, pharmaceutical manufacturing, and chemical processing.

Process Efficiency: To maintain consistent flow rates and pressure, preventing clogging and downtime in critical systems.

Product application

Wastewater

Water & liquid applications

Corrosion – resistant materials make vessels suitable for hot water and high pressure applications as well as a range of industrial and commercial usages. Also compatible with high-purity water and fluids.

Chemical fluid treatment

Oil & Gas

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China