Product description

DAGYEE offers a variety of different filter cartridge housings for industrial and food applications. For industrial filtration tasks, our filter cartridge housings are an economical solution for price-sensitive applications. For demanding industrial applications, the cartridge filter housings are the best choice. For food and beverage filtration, filter cartridge housings made of stainless steel are an excellent choice. DAGYEE also manufactures housings for air, steam, and gas filtration applications. Additionally, we produce measuring and testing devices for determining the filterability of liquids and for integrity tests on membrane filter cartridges.

Product function

Handles High Flow Rates: Meets the filtration demands of high-velocity applications.

Holds More Contaminants: Extends filtration cycles and reduces change-out frequency.

Built-in System Redundancy: A single cartridge failure does not halt the entire operation.

Integrated Design: Consolidates multiple filtration points into one unit, simplifying the system.

Product technical

Seal type: O-rings and flat gasket

Sealing material: nitrile rubber(chemitum), silicone, fluorine rubber, usually use silicon

Rubber seal Filter interface: the threaded, clamp(hoop), GB, HG, DIN, ANSI

Filtration accuracy: 1μm - 100 μm

Body material: SS304/SS 316

Single filter Cartridges housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Diameter mm |

|---|---|---|---|---|---|---|

| DYG-1-10" | 0.5 M³/H | 6/120 | Ø65*250 | 1/2" | 380 | Ø89 |

| DYG-1-20" | 1 M³/H | 6/120 | Ø65*500 | 3/4" | 630 | Ø89 |

| DYG-1-30" | 1.5 M³/H | 6/120 | Ø65*750 | 1" | 880 | Ø89 |

| DYG-1-40" | 2 M³/H | 6/120 | Ø65*1000 | 1" | 1130 | Ø89 |

Single microporous filter housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet-Quick Connector | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-C1-10" | 0.5 M³/H | 6/120 | Ø68*250 | 1 1/4" | 608 | Ø102 |

| DYG-C1-20" | 1 M³/H | 6/120 | Ø68*500 | 1 1/4" | 850 | Ø102 |

| DYG-C1-30" | 1.5 M³/H | 6/120 | Ø68*750 | 1 1/4" | 1100 | Ø102 |

| DYG-C1-40" | 2 M³/H | 6/120 | Ø68*1000 | 1 1/4" | 1350 | Ø102 |

5 Cartridges filter Housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-5-10" | 2.5 M³/H | 6/150 | Ø65*250 | 3/4" | 550 | Ø219 |

| DYG-5-20" | 5 M³/H | 6/150 | Ø65*500 | 1" | 850 | Ø219 |

| DYG-5-30" | 7.5 M³/H | 6/150 | Ø65*750 | 1 1/2" | 1100 | Ø219 |

| DYG-5-40" | 10 M³/H | 6/150 | Ø65*1000 | 2" | 1390 | Ø219 |

5 Cartridges filter Housings with flange

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-5F-10' | 2.5 M³/H | 0-1.0MPa | Ø65*250 | 3/4" | 550 | Ø219 |

| DYG-5F-20' | 5 M³/H | 0-1.0MPa | Ø65*500 | 1" | 850 | Ø219 |

| DYG-5F-30' | 7.5 M³/H | 0-1.0MPa | Ø65*750 | 1 1/2" | 1100 | Ø219 |

| DYG-5F-40' | 10 M³/H | 0-1.0MPa | Ø65*1000 | 2" | 1390 | Ø219 |

Single bag filter housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-1-1S | 18 M³/H | 12/150 | Ø180*410 | 1 1/2" flange | 1040 | Ø219 |

| DYG-1-2S | 36 M³/H | 12/150 | Ø180*810 | 2" flange | 1300 | Ø219 |

| DYG-1-4S | 10 M³/H | 12/150 | Ø105*380 | 1 1/2" BSP female | 850 | Ø133 |

| DYG-1K-1S | 18 M³/H | 12/150 | Ø180*410 | 1 1/2"flange | 1010 | Ø219 |

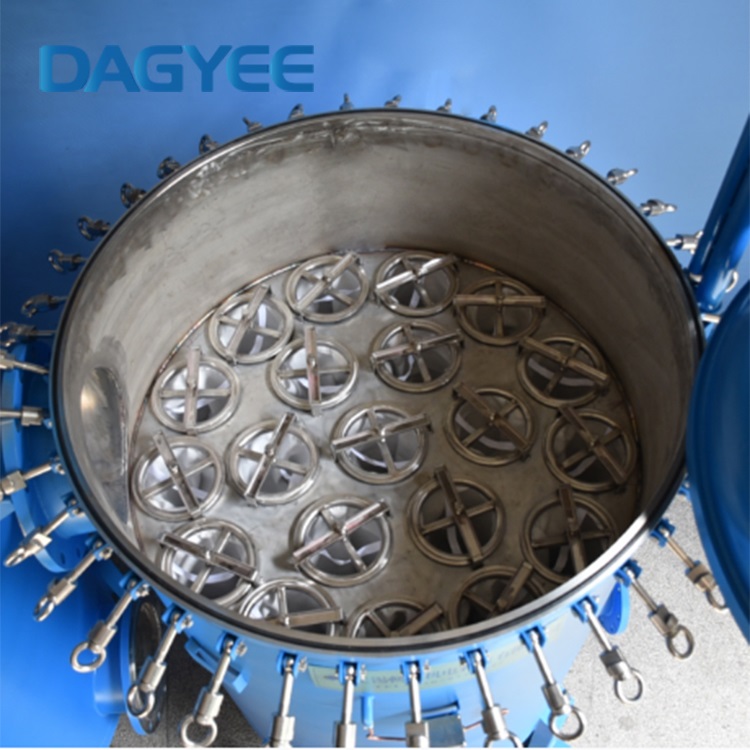

Multi Bag Filter Housings

| Model | Max. Flow Rate (m³/h) | Max. Operating Conditions (bar/°C) | Filter specifications | Inlet/Outlet | Height mm | Max. Cartridge Outside Diameter |

|---|---|---|---|---|---|---|

| DYG-2D-2S | 70 M³/H | 12/150 | Ø180*810 | 2" | 1600 | Ø420 |

| DYG-3D-2S | 100 M³/H | 12/150 | Ø180*810 | 3" | 1800 | Ø506 |

| DYG-4D-2S | 130 M³/H | 12/150 | Ø180*810 | 4" | 1800 | Ø506 |

| DYG-6D-2S | 200 M³/H | 12/150 | Ø180*810 | 4" | 2100 | Ø650 |

| DYG-8D-2S | 250 M³/H | 12/150 | Ø180*810 | 5" | 2100 | Ø710 |

| DYG-12D-2S | 400 M³/H | 12/150 | Ø180*810 | 6" | 2100 | Ø910 |

High-Efficiency Processing, Ensures Production: Capable of handling high-flow conditions that single-cartridge housings cannot meet, directly supporting main production lines and boosting overall capacity.

Extended Service Cycles, Reduces Costs: The high dirt-holding capacity significantly extends intervals between cartridge changes, reducing consumable costs and maintenance labor expenses.

System Redundancy, Ensures Operational Reliability: Even if one or several cartridges become clogged or damaged, the remaining cartridges continue to operate, providing a buffer for scheduled maintenance and effectively preventing unplanned downtime.

Top-Service Design: Features a large, removable top head or bolted cover for easy access to all cartridges simultaneously, simplifying maintenance.

Integrated Accessories: Often includes accessories like pressure gauges (inlet/outlet), vent valves, and drain valves for operational control and safety.

Scalability: Available in various sizes and cartridge counts (e.g., 3, 7, 12, 21-cartridge models) to match specific flow rate requirements.

Product application

Food & Beverage: Water purification, ingredient filtering, wine and beer stabilization, edible oil processing.

Pharmaceutical & Biotech: Purification of water for injection (WFI), process fluids, solvent filtration, sterile venting.

Chemicals & Petrochemicals: Chemical purification, catalyst recovery, pre-filtration for membranes.

Electronics: Ultra-pure water production for semiconductor and PCB manufacturing.

Metalworking & Plating: Coolant filtration, pre-treatment of plating baths.

General Industrial: Water treatment, hydraulic and lubricating oil protection, compressed air and gas filtration.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China