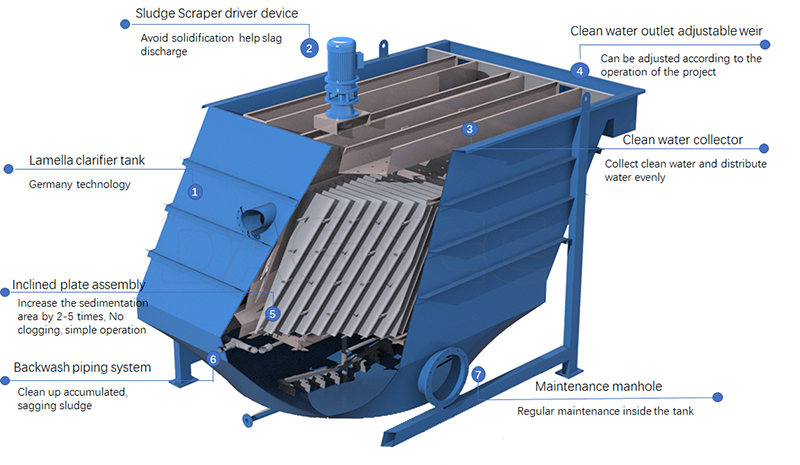

Lamella Separator Description

Lamella clarifier inclined plate settler (IPS) a type of settler designed to remove particulates from liquids.

They often employed in primary water treatment in place of conventional settling tanks. used in industrial water treatment. inclined plates provide a large effective settling area for a small footprint. The inlet stream is stilled upon entry into the clarifier. Solid particles begin to settle on the plates and begin to accumulate in collection hoppers at the bottom of the clarifier unit. Sludge drawn off at the bottom of the hoppers and the clarified liquid exits the unit at the top over weir.

Available options

•Flash mixing/flocculation tank with agitator

•Full glass steel or stainless steel structure

•Concrete tank design

•Special coatings and plates

•Integrated mechanical sludge thickener

•Overhaul platforms and ladders

•In-house laboratory analysis to optimize equipment

•Drinking water design

•Gasket and removable cover

•Automatic desilting

•Instrumentation and control

•Chemical feed equipment

•Sludge treatment and dewatering

•Pilot size units for field testing

Lamella Separator Model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

DLC

Model

Capacities

(m3/h)

Piping Connections()

Physical Dimensions(m)

Inlet(a)

Effluent(b)

Sludge(c)

Backwash(d)

L

W

H

DLC-

5

80

80

50

50

2.55

1.6

2.9

DLC-

10

100

100

50

50

3.35

1.82

3

DLC-

15

100

100

50

50

3.35

2.02

3

DLC-

20

100

100

50

50

3.35

2.02

3

DLC-

30

150

150

50

50

4.2

2.22

3

DLC-

40

150

150

50

50

4

2.8

3

DLC-

50

200

200

50

50

4.65

2.82

3

DLC-

60

200

200

50

50

4.7

3

3

DLC-

70

250

200

50

50

6.4

2.6

3

DLC-

80

250

200

50

50

6.8

2.82

3

DLC-

100

250

250

50

50

7.05

3.02

3

Lamella Separator Advantages

Construction Materials

A wide range of construction materials and coatings are available to meet specific needs: Mild steel, Stainless steel, FRP, Plastics — PVC, Polypropylene, and many others.

DAGYEE Plate Cleaning Wand: Powerful Preventative Maintenance Tool

DAGYEE has developed a very effective tool for removing solids and debris accumulated on the separator plates of lamella-style inclined plate clarifiers: This product has been developed as part of our continued effort to improve operations and maintenance for your plant, and is the perfect compliment to all of our Plate Clarifiers.

The product is ideal for in-place cleaning of separator plates and is intended for use while the unit is in operation – greatly reducing downtime required during routine maintenance procedure.

Optional Features/Equipment

1. A flash mixer and flocculator tank are available pre-treatment options.

2. Chemical feed pumps

3. A sludge thickening tank with mechanical drive is available for post-settling sludge treatment.

4. Covers are available in a variety of materials to prevent algae growth, protect the water stream, and control harmful vapors/fumes.

5. Access ladders, platforms, and railings can be included to accommodate site specific requirements.

6. Complete electrical controls are available to meet customer requirements.

Lamella Separator Applications

Lamella clarifiers are extensively used in the wastewater treatment process due to their efficiency in separating solids from liquids. These systems are particularly beneficial where the footprint area is limited as they provide a large settling area in a compact space. Below is a list of common applications:

Municipal Water Treatment: They are often employed in municipal water treatment plants to enhance sedimentation in both primary and secondary treatment stages.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China