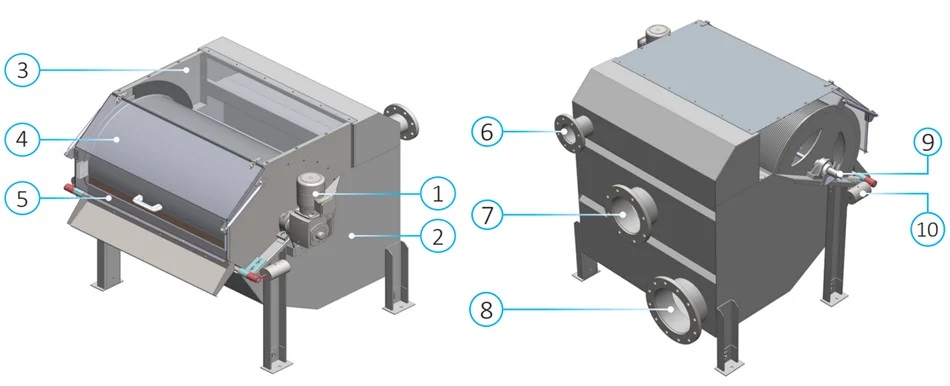

Externally Fed Rotating Drum Screen Description

Externally fed drum screen provides advanced solids removal for wastewater treatment, specifically designed for municipal and industrial facilities. Its durable stainless steel structure and automatic self-cleaning mechanism offer reliable, low-maintenance performance, effectively handling solids separation under demanding conditions.

Influent flows evenly across the rotating drum surface, capturing solids on the exterior screen while filtered water passes through. Continuous drum rotation and internal spray cleaning prevent clogging, delivering uninterrupted operation. The compact, enclosed design minimizes odor, reduces maintenance needs, and optimizes overall treatment efficiency.

Externally Fed Rotating Drum Screen Function

In an externally fed design, wastewater enters a headbox where it is evenly distributed onto the outer surface of the rotating drum. Solids larger than the screen opening size are trapped and gradually conveyed by the drum rotation to a discharge point. Fine particles are efficiently captured, while the liquid filtrate passes through the screen and continues in the treatment process.

Some models also feature a spray bar system for automatic cleaning, maintaining peak filtration performance over extended periods.

Externally Fed Drum Screen Advavtage

High Efficiency: With an optimized screening surface, these rotary drum screens for wastewater treatment deliver superior removal of fine particles, protecting pumps, membranes, and other critical equipment.

Low Maintenance: Robust design and automatic self-cleaning features, such as integrated spray bars, and maintenance of rotary drum screens is simple and infrequent.

Externally Fed Rotating Drum Screen Feature

Externally Fed Rotating Drum Screen Application

Civil purification plants

Process of Water separation

Treatment of Industrial waste water such as;

1. Paper Mills

2. Food Industry

3. Chemical Industry

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China