Static screen wastewater description

When wastewater flows into a treatment plant, a static screen sits in front of the remaining wastewater equipment.

Wastewater enters the system, passing through a stationary static screen first to remove as many solids as possible.

Think of it like a mesh screen that keeps bugs from entering your window at home.

In this case, it’s a durable screen that catches particles like plastics, feminine products, foods that weren’t digested, hardened particles of grease, and paper products.

Items that get captured are composted or removed and taken to a landfill.

Many plants compost them over time, and that compost can be used in forests.

This makes it easier for the next stages of wastewater treatment, such as grit removal.

In addition to a municipal wastewater treatment system, static screens benefit businesses that are under orders to pre-treat industrial wastewater or who want to do their part.

It includes companies like chemical processing plants, paper mills, breweries, food processing plants, and plastic and metal processing plants.

If you have a stormwater system, they are fantastic for removing plastics, trash, and fallen sticks and branches after a storm.

Static screen wastewater works

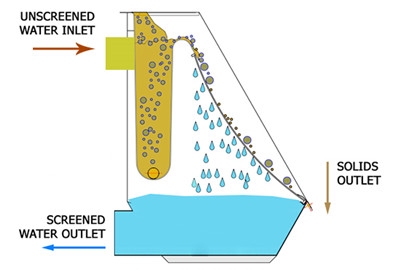

The operation of the Static Screen is based on the Coanda effect meaning that the liquid to be screened forms a hydraulic attachment to the wedge wire (bars) of the screen.

The water goes through the slots while the separated solids stay on the front face of the screen plate.

The screen plate has a design with three distinct angles to increase the separation efficiency.

Static screen wastewater model

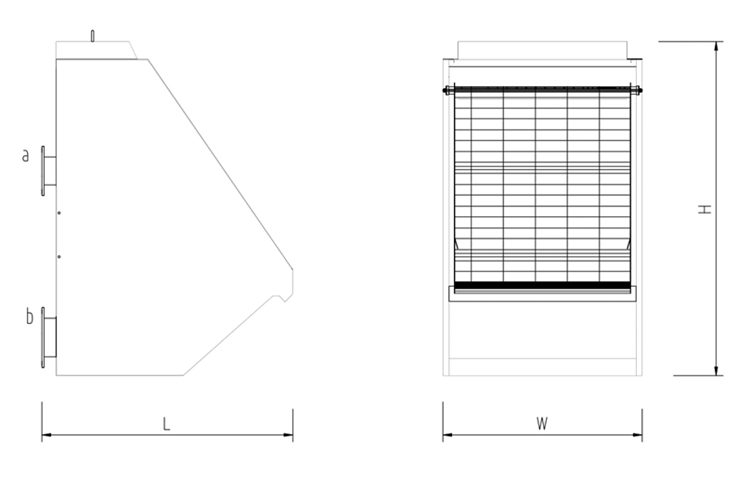

| HS Model |

Piping Connections Inlet(a) | Effluent(b) |

Physical Dimensions(m) L | W | H |

Weight (Kg) |

Capacities(m³/h) 0.5mm | 1mm | 1.5mm |

|---|---|---|---|---|

| HS-300 | 80 | 80 | 1.43 | 0.43 | 2 | 150 | 6 | 13 | 16 |

| HS-500 | 100 | 100 | 1.43 | 0.63 | 2 | 180 | 10 | 22 | 35 |

| HS-700 | 100 | 100 | 1.43 | 0.83 | 2 | 200 | 15 | 30 | 50 |

| HS-800 | 100 | 125 | 1.43 | 0.93 | 2 | 250 | 16 | 35 | 55 |

| HS-1000 | 150 | 150 | 1.43 | 1.13 | 2 | 280 | 20 | 45 | 70 |

| HS-1500 | 150 | 150 | 1.43 | 1.63 | 2 | 300 | 30 | 65 | 100 |

| HS-2000 | 200 | 200 | 1.43 | 2.13 | 2 | 400 | 40 | 75 | 120 |

Static screen wastewater advantage

Get economical, effective CSO screening

The Hydro-Static Screen provides effective gross solids and floatables capture and works with small flows and small budgets.

Mesh screen panels are coated in a non-stick polymer and corrugated to increase flow-through capacity.

Reduce maintenance requirements

The Hydro-Static Screen has no moving parts and requires no power to operate. Patented flow-modifying components provide partial cleansing of the screen, and a polymer

coated mesh reduces the risk of blinding.

Installs quickly and easily

Components can be pre-installed in a precast concrete chamber to enable swift installation on site.

Static screen wastewater feature

1. Material : AISI304 / 316 Stainless Steel.

2. Screen Range : 0.5 mm – 3 mm.

3. Cleaning : Manuel / Automatic (Optional).

4. Waste Hopper: Optional.

Static screen wastewater application

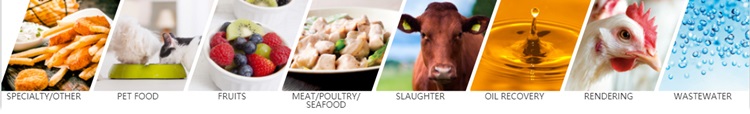

Vegetable, fruit and potato processing industry

Sugar industry

Meat and poultry processing / abattoirs / rendering industry

Fish and shellfish processing industry

Brewing, malting and beverage industry / distilleries

Starch and gluten processing industry

Food ingredients and hydrocolloids industry

Pharmaceutical industry

Horticulture industry

Zoos

Textile industry / laundries

Paper and pulp industry

Chemical and petrochemical industry

Mining and minerals industry

Exhaust gas cleaning

Tanneries

Waste recycling industry

Bioenergy industry

Sewage water treatment

Drinking water plants

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China