Static screen wastewater description

The Hydro-Static Screen is a corrugated, polymer-coated perforated screen with 4.2m apertures.

It is comprised of a static corrugated panels, through which sewer overflows flow up and out.

The under side of the Hydro-Static Screen has flow-modifying baffles to discourage screenings in the flow from disproportionately loading one part of the screen.

The turbulance caused by the baffles encourages screenings to be spread evenly across the surface area of the screen.

The static screen requires no power, no control panel, and has no replacement parts.

The Hydro-Static Screen is recommended for sewers or wastewater treatment plants with infrequently occuring overflows.

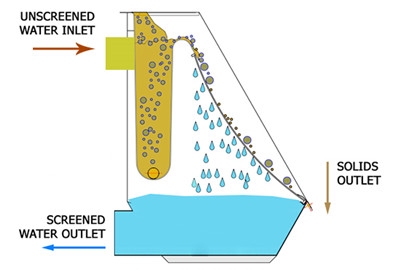

Static screen wastewater works

Wastewater, or process water, enters the headbox where a special baffle modifies hydraulic turbulence so the influent and suspended solids will flow over the wire and onto the

screen face evenly.

The triangular cross section of the wedgewire screen element then strips the liquid from the solids allowing the effluent to travel on for further treatment.

The recovered solids then continue downward on the face of the screen, where additional moisture evaporates until the screenings drop off the face of the screen.

The screenings are then disposed of to a landfill, screenings press, or dewatered further for incineration.

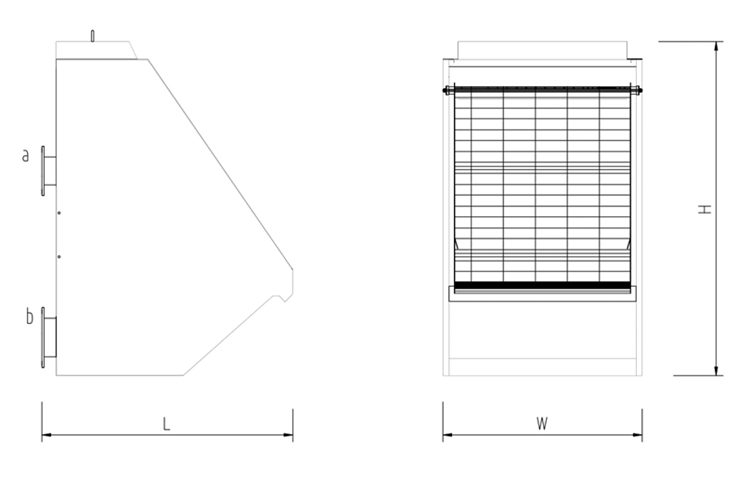

Static screen wastewater model

| HS Model |

Piping Connections Inlet(a) | Effluent(b) |

Physical Dimensions(m) L | W | H |

Weight (Kg) |

Capacities(m³/h) 0.5mm | 1mm | 1.5mm |

|---|---|---|---|---|

| HS-300 | 80 | 80 | 1.43 | 0.43 | 2 | 150 | 6 | 13 | 16 |

| HS-500 | 100 | 100 | 1.43 | 0.63 | 2 | 180 | 10 | 22 | 35 |

| HS-700 | 100 | 100 | 1.43 | 0.83 | 2 | 200 | 15 | 30 | 50 |

| HS-800 | 100 | 125 | 1.43 | 0.93 | 2 | 250 | 16 | 35 | 55 |

| HS-1000 | 150 | 150 | 1.43 | 1.13 | 2 | 280 | 20 | 45 | 70 |

| HS-1500 | 150 | 150 | 1.43 | 1.63 | 2 | 300 | 30 | 65 | 100 |

| HS-2000 | 200 | 200 | 1.43 | 2.13 | 2 | 400 | 40 | 75 | 120 |

Static screen wastewater advantage

1. Economic purchase price.

2. No moving parts.

3. Quick and easy installation.

4. Does not require power supply.

5. fine screens filtration starting from 0.25mm.

6. Very low maintenance.

Static screen wastewater feature

1. Eco-friendly solution: energy-free.

2. No moving parts, no motors.

3. Low maintenance.

4. Quiet operation.

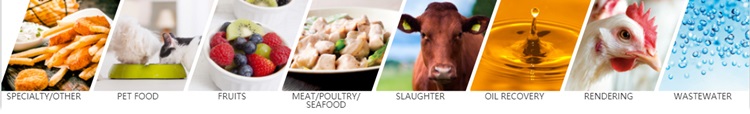

Static screen wastewater application

According to different kinds of sewage, static screen can remove suspended solids, float scum, etc.

As the primary treating process, static screen can replace of sedimentation tank reducing large numbers of job, strengthening the biological treating process and saving running

cost.

Static screen can also be used for solid-liquid separation and thickening.

Typical application industry:

Paper-making industry - recycling of fiber , removing solids.

Tannery wastewater - removing of feather , oil and grease.

Slaughterhouse wastewater - removing of bag , fur , grease and feces.

Municipal wastewater - removing fur , debris .

Alcohol plant, starch factory - removal of solid substances such as vegetable fiber, hulls, groceries, etc.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China