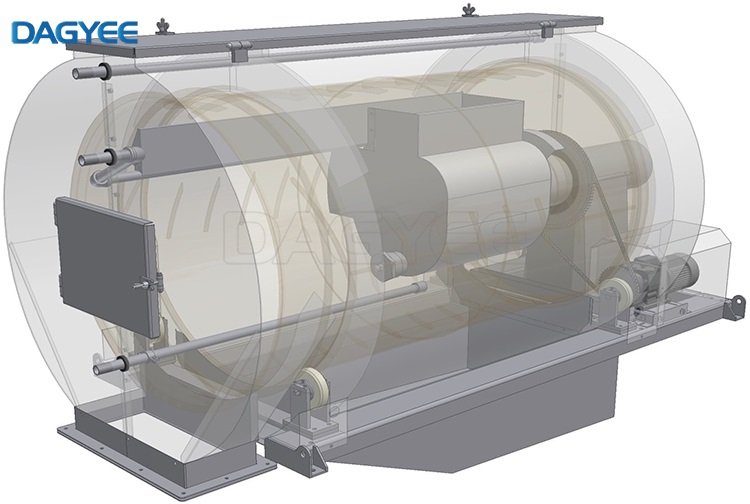

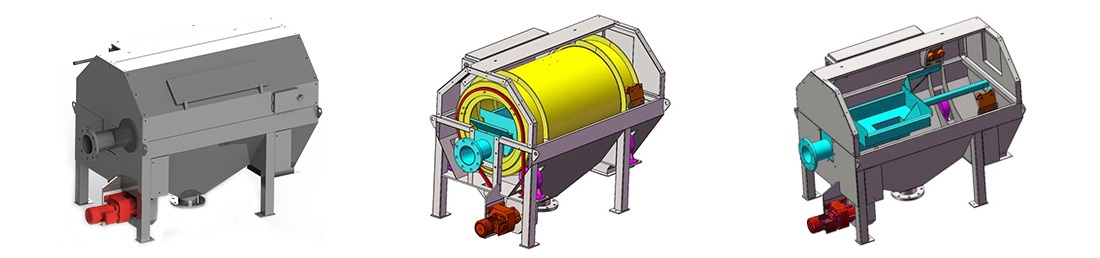

Internally rotary drum screen description

The Internally Fed Rotary Drum Screen utilizes a direct drive system to eliminate the use of belts, chains or sprockets.

A combination of stainless-steel shoes and UHMW polyethylene wear strips replace the use of trunnion wheels reducing labor intensive maintenance.

The screening panels remove easily for regular cleaning and to allow access inside the drum without disassembling the machine.

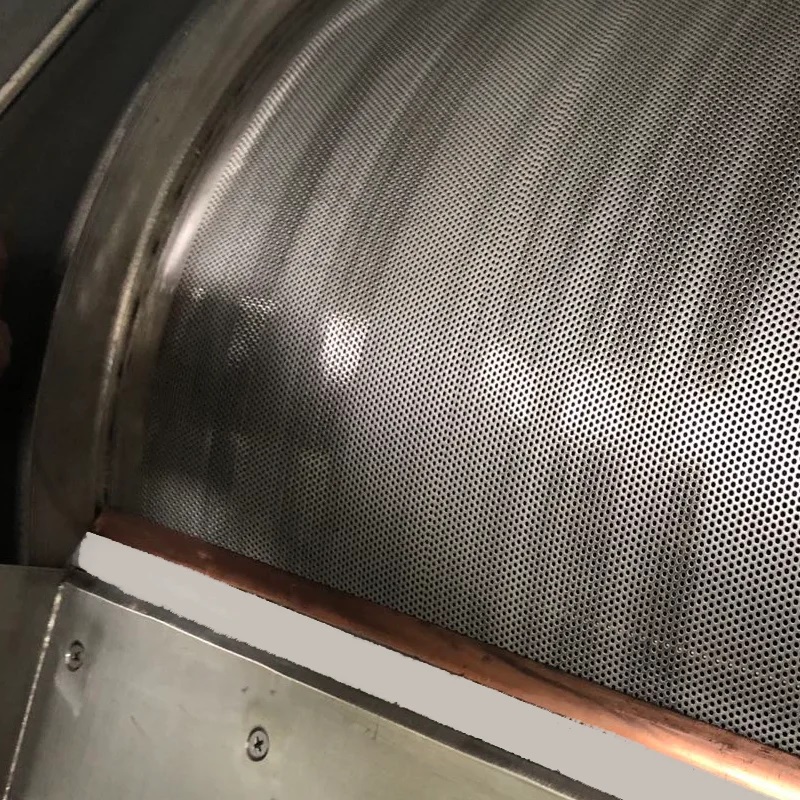

Screening panels are available in wedge wire, perforated plate and wire mesh in various opening sizes to optimize debris removal.

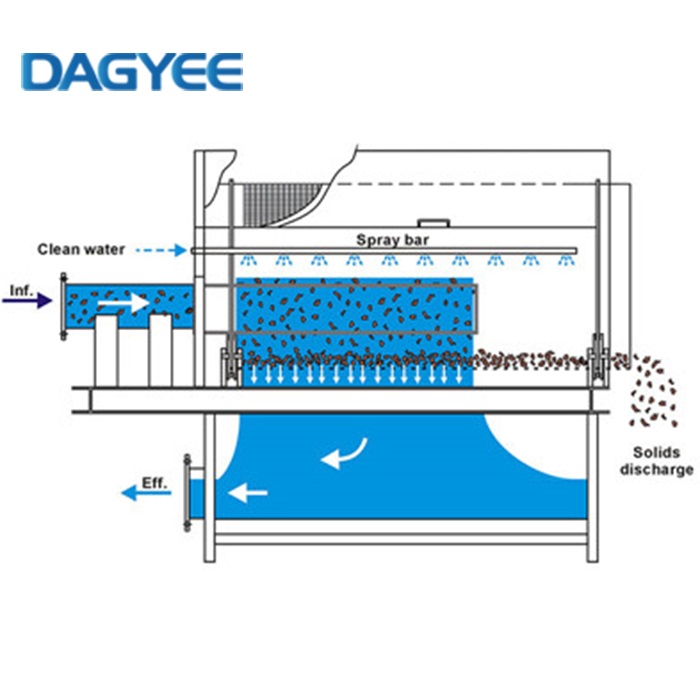

Internally rotary drum screen function

Internally fed rotary drum screen utilizes the internal surface of a wedge wire, perforated, or a wire mesh drum screen.

Wastewater is pumped inside the screen and the flow is distributed equally to the internal surface by the help of a distribution weir.

While the wastewater flows through, the solid waste gets stuck on the internal screen surface.

Screenings get drained as they move up and then discharged at the top of the drum screen into a conveyor with the help of a pressured nozzle system located on the outer side.

Internally rotary drum screen model

| DIRD Model | Drum size | Physical Dimensions(mm) | Power | Weight (Kg) | Capacities(m³/h) | Sludge height |

|---|---|---|---|---|---|---|

| L W H | kW | 1mm 2mm 3mm | mm | |||

| IRD6-900 | Ø600×900 | 1900 1350 1700 | 0.55 | 630 | 15 25 30 | 500 |

| IRD6-1200 | Ø600×1200 | 2200 1350 1700 | 0.55 | 820 | 30 50 60 | 500 |

| IRD6-1500 | Ø600×1500 | 2500 1350 1700 | 0.75 | 1000 | 45 70 85 | 500 |

| IRD6-1800 | Ø600×1800 | 2800 1350 1700 | 0.75 | 1160 | 60 100 120 | 500 |

| IRD6-2100 | Ø600×2100 | 3100 1350 1700 | 1.1 | 1300 | 80 135 170 | 500 |

| IRD9-1200 | Ø900×1200 | 2300 1600 2200 | 1.1 | 1200 | 40 70 85 | 600 |

| IRD9-1800 | Ø900×1800 | 2900 1600 2200 | 1.1 | 1470 | 80 135 170 | 600 |

| IRD9-2500 | Ø900×2500 | 3600 1600 2200 | 1.5 | 1800 | 120 200 250 | 600 |

| IRD9-3000 | Ø900×3000 | 4100 1600 2200 | 1.5 | 2100 | 160 270 350 | 600 |

Internally rotary drum screen advantage

1. Headbox design optimizes screen throughput to minimize overall size rotary drum screen.

2. Intermittent spray wash reduces water usage to clean drum screens.

3. Drum filter media optimized for various applications.

4. Robust design and all stainless steel construction reduce downtime and maintenance costs.

5. Easy access to all maintenance items.

6. Higher capture rate compared to conventional moving media screens.

Internally rotary drum screen feature

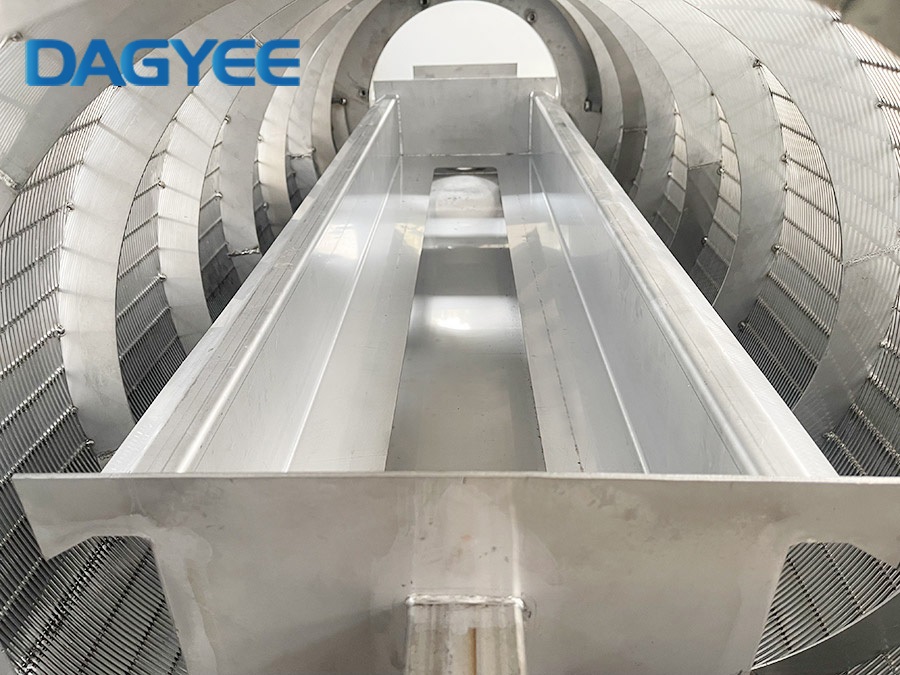

The unique design eliminates the need for trunnion wheels, sprockets and chains, which reduces the wear and tear points and increases the product’s lifespan.

Trouble-free maintenance

All routine maintenance is done at chest level. Removal of the drum is not required to perform maintenance and manual clean in place (CIP).

Designed for duty

Engineered to perform in fine screening applications that have high flows and high solids loading.

Flexible design

Quick change-out screening panels available in various opening sizes, allows for improved debris management.

Low cost of ownership

With few wear parts, a fractional horsepower motor and minimal maintenance required, Duperon equipment is easy to install, own, and operate.

Customizable

The water inlet can be designed on either side of the drum screen, providing options for difficult installation scenarios.

Internally rotary drum screen application

DAGYEE offers uncompromised performance and technical leadership when it comes to municipal wastewater treatment.

We’re proud to be the first choice for critical wastewater applications, including primary treatment plants, pump stations, sludge processing, septage and grease receiving,

airports, correction facilities and many more.

DAGYEE provides proven performance and application expertise to support industrial wastewater and processing.

We’re recognized for our premier solutions in diverse industrial applications, including food and beverage, agricultural waste, product destruction, facilities management, digestion and biogas, recycling and many more.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China