The implementation of lamella clarifiers in wastewater treatment is widely recognized due to their numerous advantages, such as their ability to handle high flow rates and their versatility across various industries. They are an essential element in the treatment process, appearing in sectors like municipal sewage treatment, industrial effluent processing, and water recycling. Proper installation and maintenance of lamella clarifiers are crucial for their optimal performance and compliance with environmental regulations. Recent technological advancements have further improved the efficacy of these systems, making them more sustainable and cost-effective solutions for wastewater management.

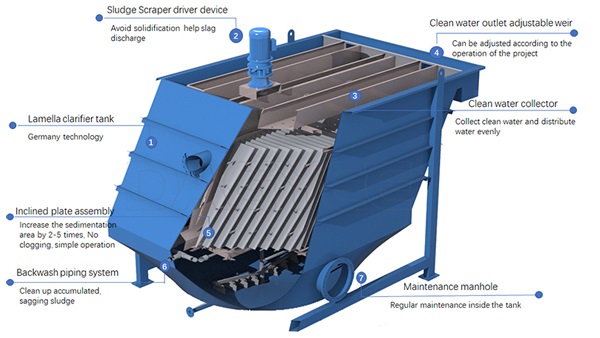

The Lamella Clarifier works on the principle of gravity separation. When wastewater enters the tank, the solids in the liquid begin to settle to the bottom of the tank due to the force of gravity. As the solids settle, they encounter the inclined plates, which increase the effective settling area and allow more solids to settle. The settled solids slide down the inclined plates to the bottom of the tank, where they collect and are removed periodically.

The clarified liquid exits the tank through the collection system located at the top of the unit. The flow rate of the liquid is controlled by an effluent weir, which maintains a constant liquid level in the tank. The effluent weir also prevents solids from escaping with the clarified liquid.

Lamella clarifier available options

• Flash mixing/flocculation tank with agitator

• Full glass steel or stainless steel structure

• Concrete tank design

• Special coatings and plates

• Integrated mechanical sludge thickener

• Overhaul platforms and ladders

• In-house laboratory analysis to optimize equipment

• Drinking water design

• Gasket and removable cover

• Automatic desilting

• Instrumentation and control

• Chemical feed equipment

• Sludge treatment and dewatering

• Pilot size units for field testing

Lamella clarifier model

DLC-I Gravity Lamella ,V shape mud bucket, simple structure, no energy consumption.

DLC-II Lamella with scraper,Increase the mechanical transmission mechanism, the mud discharge is better and smoother, and it matches the unit with large processing capacity.

DLC-III Super hydraulic Lamella,Reduced footprint, efficient sedimentation, detachable transportation.

| DLC Model | Capacities (m³/h) | Piping Connections (mm) | Physical Dimensions (m) | |||||

|---|---|---|---|---|---|---|---|---|

| Inlet(a) | Effluent(b) | Sludge(c) | Backwash(d) | L | W | H | ||

| DLC 5 | 5 | 80 | 80 | 50 | 50 | 2.55 | 1.6 | 2.9 |

| DLC 10 | 10 | 100 | 100 | 50 | 50 | 3.35 | 1.82 | 3 |

| DLC 15 | 15 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 20 | 20 | 100 | 100 | 50 | 50 | 3.35 | 2.02 | 3 |

| DLC 30 | 30 | 150 | 150 | 50 | 50 | 4.2 | 2.22 | 3 |

| DLC 40 | 40 | 150 | 150 | 50 | 50 | 4 | 2.8 | 3 |

| DLC 50 | 50 | 200 | 200 | 50 | 50 | 4.65 | 2.82 | 3 |

| DLC 60 | 60 | 200 | 200 | 50 | 50 | 4.7 | 3 | 3 |

| DLC 70 | 70 | 250 | 200 | 50 | 50 | 6.4 | 2.6 | 3 |

| DLC 80 | 80 | 250 | 200 | 50 | 50 | 6.8 | 2.82 | 3 |

| DLC 100 | 100 | 250 | 250 | 50 | 50 | 7.05 | 3.02 | 3 |

Space-saving design: The inclined plates in a Lamella Clarifier increase the effective settling area while reducing the footprint of the tank. This space-saving design is especially useful for food processing sites that have limited space for wastewater treatment.

Efficient separation: The inclined plates in a Lamella Clarifier increase the effective settling area, allowing more solids to settle in a shorter amount of time. This increased efficiency results in better separation of solids from liquid.

Low maintenance: Lamella Clarifiers require minimal maintenance compared to traditional sedimentation tanks. The inclined plates are self-cleaning, reducing the need for regular cleaning and maintenance.

DAGYEE lamella clarifiers are equipped with robust and durable lamella packages.

A wide variety of requirements are met by customizing the lamella packages with different heights, channel spacings, and inclination angles.

The lamella packages are the core element of a lamella clarifier, but the overall performance of the settling system is also determined by the associated components. These include the effluent launders, support structures, sludge scrapers, and the hydraulic design of the tank.

DAGYEE supports planning and design with engineering services on request and supplies all components of a lamella clarifier system.

Lamella clarifier application

Contact Us for a Consultation

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China