Static screen wastewater description

The Static Screen filter, known as the static sieve, separates solid and liquid substanceswithin Waste Water Treatment applications.

lt serves two primary purposes.

lt serves as the initial treatment for wastewater, utilizing a mesh size ranging from 0.5mmto 10mm.

lt is a pre-treatment solution for the solid-liquid waste separation process.

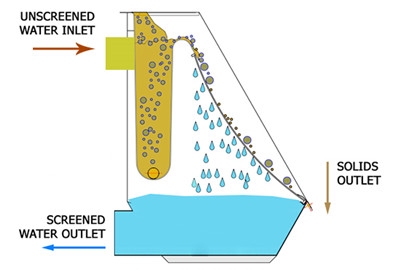

Static screen wastewater works

Static Screen head box reduces turbulence of wastewater or processed slurry and delivers flow to the wire.

A swing baffle distributes flow across the width of the screen surface and the liquid is then separated out of the slurry as it passes across the upper part of the screen panel.

Most of the solids are captured on the curved face of the screen while the liquid is drained to the bottom part via the back of the screen.

This screen provides excellent liquid/solid separation at a low capital cost and low maintenance.

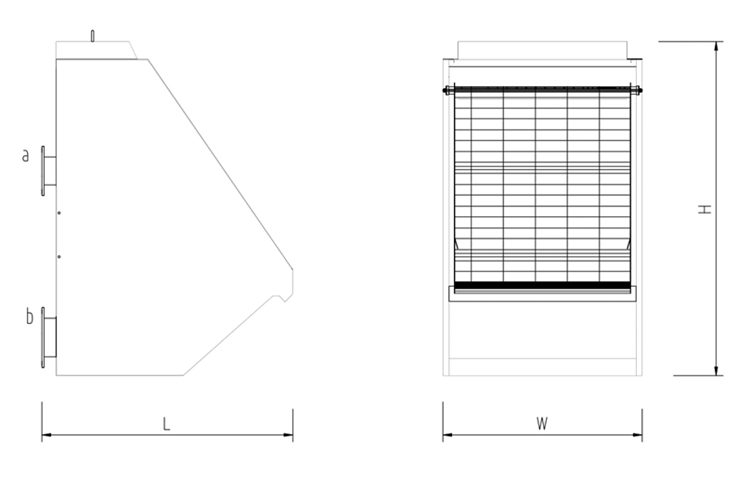

Static screen wastewater model

| HS Model |

Piping Connections Inlet(a) | Effluent(b) |

Physical Dimensions(m) L | W | H |

Weight (Kg) |

Capacities(m³/h) 0.5mm | 1mm | 1.5mm |

|---|---|---|---|---|

| HS-300 | 80 | 80 | 1.43 | 0.43 | 2 | 150 | 6 | 13 | 16 |

| HS-500 | 100 | 100 | 1.43 | 0.63 | 2 | 180 | 10 | 22 | 35 |

| HS-700 | 100 | 100 | 1.43 | 0.83 | 2 | 200 | 15 | 30 | 50 |

| HS-800 | 100 | 125 | 1.43 | 0.93 | 2 | 250 | 16 | 35 | 55 |

| HS-1000 | 150 | 150 | 1.43 | 1.13 | 2 | 280 | 20 | 45 | 70 |

| HS-1500 | 150 | 150 | 1.43 | 1.63 | 2 | 300 | 30 | 65 | 100 |

| HS-2000 | 200 | 200 | 1.43 | 2.13 | 2 | 400 | 40 | 75 | 120 |

Static screen wastewater advantage

1. Upflow screen arrangement less prone to blinding.

2. Corrugated wave panel gives more screening surface area.

3. Non-stick polymer coating discourages ragging.

4. Flow-modifying baffles on the under side of screen discourage "preferential loading"wherein one part of the screen gets an disproportionate loading of screenings in the flow.

5. No power requirements or replacement parts.

Static screen wastewater feature

A mild steel painted or galvanised carcass can be provided for our Parabolic Rundown Screens to accommodate low budgets and client specific applications.

1. 304 or 316 Grade Stainless Steel on all wetted parts.

2. Efficient separation of liquids & solids.

3. Non-mechanical and low maintenance.

4. Widths to suit flow rate & bow screen slot gap requirements.

5. No moving parts.

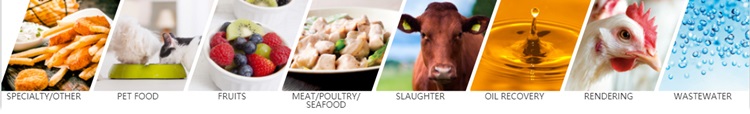

Static screen wastewater application

Wastewater Treatment: Ideal for removing suspended solids from industrial wastewater.

Food and Beverage Processing: Ensures purity and safety in the production of beverages and food products.

Pulp and Paper Industry: Efficiently separates fibers and particles in the pulp and paper manufacturing process.

Chemical Processing: Provides reliable filtration in various chemical processing applications.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China