Shaftless screw conveyor description

The conveyors are of robust and simple construction which means limited maintenance and low running costs.

The conveyors are constructed in stainless steel and after machining completely pickled. Thus, an optimal durability of material is ensured.

Transportation takes place by a shaftless screw conveyors which is embedded in a wearing plate of plastic material.

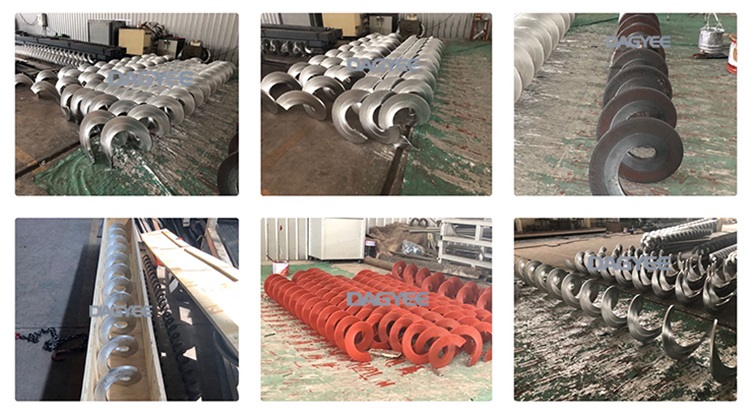

The screw is made of high-strength carbon steel with a stainless steel screw available as an option.

Shaftless screw conveyor function

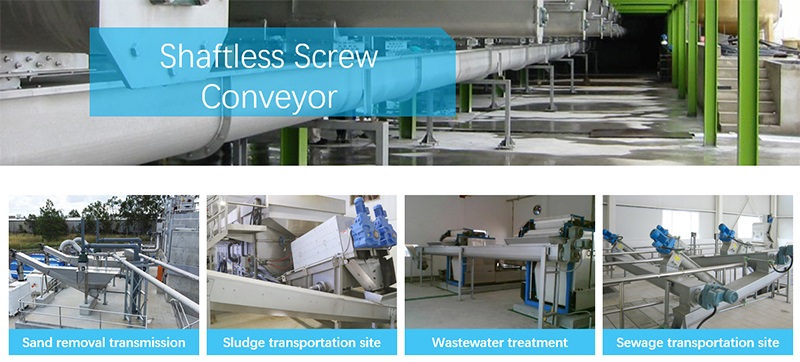

Efficient Sludge & Solid Waste Conveyance: Designed to transport dewatered sludge, grit, screenings, and other semi-solid wastes smoothly through wastewater treatment stages, from primary clarifiers to digesters or disposal points.

Clog-Free Material Handling: The shaftless spiral design prevents jamming and wrapping issues common with stringy, fibrous, or high-viscosity materials, ensuring uninterrupted process flow.

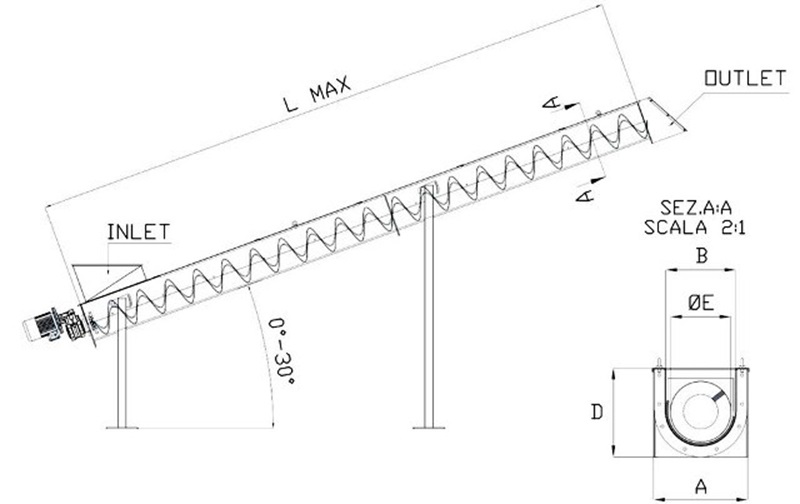

Inclined or Horizontal Conveying Flexibility: Capable of operating at various angles (up to 30° inclination) to fit space-constrained layouts, efficiently moving materials between different levels of the treatment plant.

Shaftless screw conveyor technical

Shaftless screw conveyor model

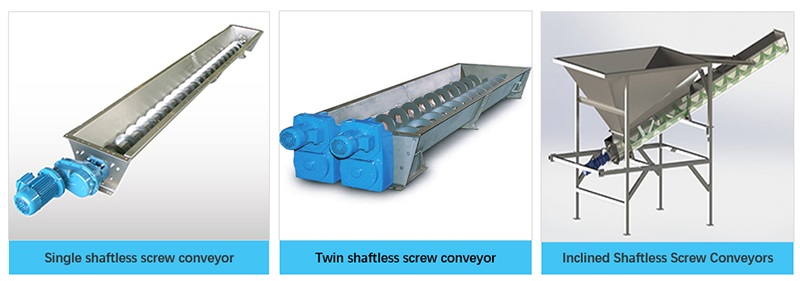

1. Single shaftless screw conveyor screw shaft, without mixing and stirring functions.

2. Twin Shaftless Screw Conveyor It adopts double screw blades with mixing and stirring functions.

3. The two screw blades rotate in opposite directions to avoid material blocking.

4. The conveying capacity is 1.5-2 times that of a single shaft.

5. Inclined Shaftless Screw Conveyor mainly used for conveying materials at a small angle of 25°.

| DLS Model | Capacities (m³/h) | Length (m) | Speed (r/min) | Size A (mm) | B (mm) | B0 (mm) | ||

|---|---|---|---|---|---|---|---|---|

| 0° | 15° | 30° | (m) | (r/min) | (mm) | (mm) | (mm) | |

| DLS200 | 2 | 1.4 | 0.9 | 10 | 20 | 200 | 200 | 200 |

| DLS260 | 3.5 | 2.5 | 1.5 | 10 | 20 | 260 | 260 | 260 |

| DLS320 | 9 | 6.5 | 4.1 | 15 | 20 | 320 | 320 | 320 |

| DLS355 | 11.5 | 7.8 | 5.5 | 20 | 20 | 355 | 355 | 355 |

| DLS420 | 15 | 11 | 7.5 | 20 | 20 | 420 | 420 | 420 |

| DLS500 | 30 | 25 | 21 | 20 | 20 | 500 | 500 | 500 |

Shaftless screw conveyor advantage

1. Easy to access and clean.

2. Low maintenance.

3. Modular components enable easy adaptation to various problems.

4. High degree of self-cleaning.

Shaftless screw conveyor feature

1. Shaftless Spiral Design: Eliminates the central shaft and intermediate bearings, reducing clogging points and allowing for the handling of sticky, cohesive materials.

2. Heavy-Duty Construction: Made from wear-resistant steel or optional stainless steel (304/316) for enhanced corrosion resistance in harsh, abrasive, and chemically aggressive environments.

3. Low Maintenance Operation: No internal bearings within the trough, minimizing wear parts and lubrication needs, leading to reduced maintenance costs and downtime.

4. Customizable Trough & Covers: Fully enclosed trough with sealed covers prevents odor escape and spillage, meeting environmental and safety standards for indoor or outdoor installation.

5. High Loading Capacity: Optimized spiral pitch and diameter allow for higher volumetric throughput compared to traditional shafted conveyors of similar size.

6. Energy-Efficient Drive System: Equipped with a reliable gear motor (IP55 protection) and optional variable frequency drive (VFD) for smooth start-up and speed control to match process demands.

7. Easy Access & Inspection: Removable cover sections and inspection ports facilitate quick visual checks, cleaning, and maintenance without disassembly.

8. Tailored Engineering Support: Available in custom lengths, diameters, and configurations (U-trough or tubular) to integrate seamlessly with your existing water treatment equipment.

Shaftless Screw Conveyors VS Shafted Screw Conveyors

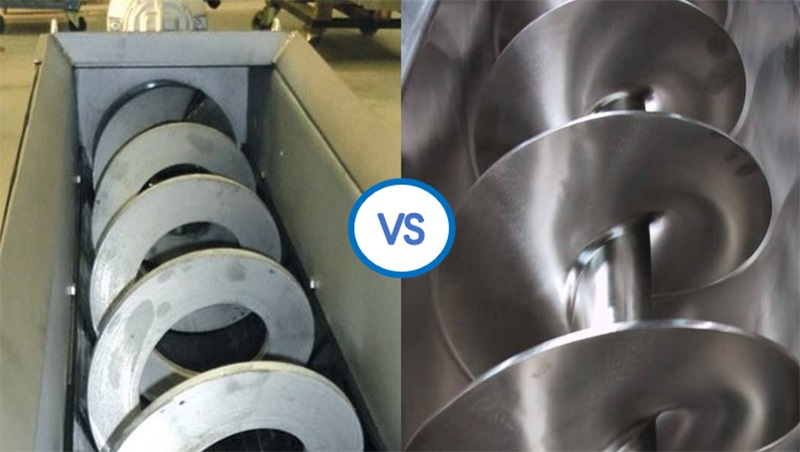

Shaftless is suitable for conveying sludge, household garbage, grid slag and other viscous, entangled materials and massive materials.

It is precisely because the design of the shaftless screw conveyor without a central axis has great advantages for these materials.

The shaft screw conveyor is suitable for conveying materials: powder, small particle materials, etc.

If you convey viscous materials such as sludge, it will stick to the inner tube shaft and blades, and the conveying block materials are easy to jam.

Conveying form

Shaftless screw conveyor is suitable for: horizontal conveying, and the large inclination angle should not exceed 20°, according to the actual usage.

The shaft screw conveyor is suitable for: horizontal conveying, inclined conveying, and vertical conveying.

Conveying capacity

Due to the use of shaftless, the single-machine conveying length of the shaftless screw conveyor can reach 60 meters, and the conveying capacity is 1.5 times that of the traditional shafted screw conveyor with the same diameter.

Shaftless Screw Conveyors Application

Food industry: soybean, peanut, starch, milk powder, salt, sugar, etc.

Plastics industry: plastic powder, plastic particles, etc.

Wood industry:wood chips, wood sawing surface and byproducts, etc.

Environmental: the filter material, fly ash, fixed residue, waste, etc.

Agriculture:livestock feed, food, powder, etc.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China