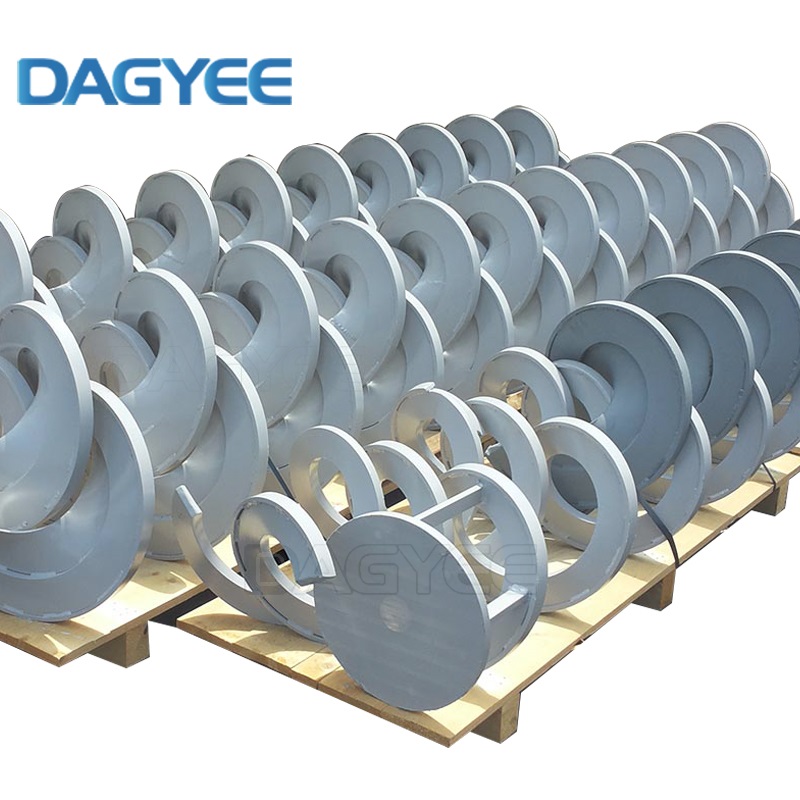

Shaftless screw flight descriprtion

The Shaftless Screw Flight is an innovative and highly efficient conveying component specifically engineered for handling challenging, viscous, and semi-solid materials in water and wastewater treatment applications.

Unlike traditional screw conveyors with a central shaft, its unique open-core, helical design eliminates the common clogging and wrapping issues, ensuring continuous, smooth, and reliable material transport.

It is the ideal solution for moving dewatered sludge, screenings, grit, and other difficult waste streams within treatment plants, significantly improving operational efficiency and reducing maintenance downtime.

Crafted from durable materials like stainless steel or abrasion-resistant alloys, it is built to withstand harsh, corrosive environments.

Shaftless screw flight function

Continuous Non-Clogging Conveyance: The absence of a central shaft prevents materials from wrapping around and jamming the mechanism, enabling uninterrupted transport of stringy, fibrous, and sticky substances like rags and plastics.

Efficient Sludge & Solids Handling: Specifically designed to move dewatered biosolids, screenings from bar screens, grit from chambers, and other semi-solid wastes from one process stage to the next (e.g., from a press to a hopper).

Self-Cleaning Operation: The rotating helical flight, combined with the open design, allows for a natural self-cleaning action as material is pushed forward, minimizing buildup and residue inside the conveyor trough.

Space-Optimized Transport: Its ability to convey materials at various inclinations within a compact, enclosed trough makes it an excellent choice for facilities with limited space, efficiently moving material horizontally or on an incline.

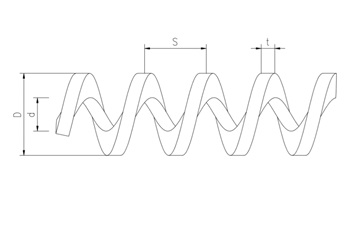

Shaftless screw flight model

| NO. | Diameter (D) | Bottom diameter (d) | Leaf height (c) | Pitch (S) | Length (mm) | Thickness (mm) | Density (kg/m³) | Weight (kg/m) |

|---|---|---|---|---|---|---|---|---|

| 1 | 200 | 80 | 60 | 200 | 1000 | 16 | 7.85 | 18.48 |

| 2 | 220 | 80 | 70 | 220 | 1000 | 20 | 7.85 | 26.46 |

| 3 | 220 | 100 | 60 | 220 | 1000 | 16 | 7.85 | 18.99 |

| 4 | 220 | 100 | 60 | 220 | 1000 | 18 | 7.85 | 21.37 |

| 5 | 220 | 100 | 60 | 220 | 1000 | 20 | 7.85 | 23.74 |

| 6 | 260 | 100 | 80 | 260 | 1000 | 20 | 7.85 | 30.56 |

| 7 | 260 | 120 | 70 | 260 | 1000 | 16 | 7.85 | 22.24 |

| 8 | 260 | 120 | 70 | 260 | 1000 | 18 | 7.85 | 25.02 |

| 9 | 260 | 120 | 70 | 260 | 1000 | 20 | 7.85 | 27.80 |

| 10 | 280 | 120 | 80 | 280 | 1000 | 20 | 7.85 | 31.24 |

| 11 | 280 | 140 | 70 | 280 | 1000 | 18 | 7.85 | 25.52 |

| 12 | 300 | 140 | 80 | 300 | 1000 | 18 | 7.85 | 28.67 |

| 13 | 300 | 140 | 80 | 300 | 1000 | 20 | 7.85 | 31.85 |

| 14 | 320 | 160 | 80 | 320 | 1000 | 20 | 7.85 | 43.22 |

| 15 | 320 | 160 | 80 | 320 | 1000 | 22 | 7.85 | 37.64 |

| 16 | 380 | 220 | 80 | 380 | 1000 | 25 | 7.85 | 42.88 |

| 17 | 380 | 120 | 130 | 380 | 1000 | 25/20 | 7.85 | 54.14 |

| 18 | 460 | 300 | 80 | 460 | 1000 | 25 | 7.85 | 43.78 |

| 19 | 460 | 180 | 140 | 460 | 1000 | 20/25 | 7.85 | 60.13 |

| 20 | 560 | 400 | 80 | 560 | 1000 | 30 | 7.85 | 57.82 |

Shaftless screw flight advantage

1. Eliminates Jamming: The shaftless design fundamentally solves the problem of material entanglement and bridging around a central shaft, drastically reducing operational stoppages.

2. Reduces Maintenance: With fewer points for material accumulation and no shaft bearings within the conveyed medium, it requires less frequent cleaning and mechanical intervention, lowering long-term operational costs.

3. Handles Difficult Materials: Excellently manages materials that would typically clog standard screw conveyors, including sticky sludge, municipal screenings, grease, and industrial wastes.

4. Improves Plant Efficiency: Ensures a consistent and reliable flow of materials between process units, preventing bottlenecks and enhancing overall treatment plant throughput.

5. High Durability: Manufactured from wear-resistant materials with thick flight sections, it offers an extended service life even under abrasive and corrosive conditions.

6. Greater Loading Capacity: The open core allows for a higher volumetric fill rate compared to shafted screws, enabling more material to be moved per revolution.

Shaftless screw flight feature

1. Shaftless Helical Design: A continuous, robust helical flight without a center shaft, forming the core functional element.

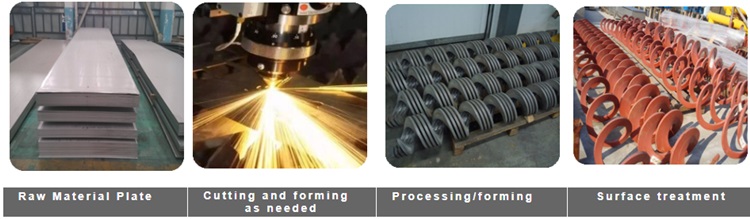

2. Heavy-Duty Construction: Typically fabricated from thick-grade stainless steel (304/316) or carbon steel with protective coatings for strength and corrosion resistance.

3. Customizable Geometry: Available in various diameters, pitches, and thicknesses to match specific flow rates, material characteristics, and trough dimensions.

4. Bolt-On or Welded Sections: Can be supplied in standard or custom lengths, often segmented for easier installation, transport, and future replacement.

5. Reinforced Flight Edge: Often features a hardened or reinforced outer edge to maximize wear life against the trough liner.

6. Compatible with U-Trough: Engineered to rotate within a standard U-shaped trough, often with a wear-resistant liner, forming a complete conveying system.

Shaftless screw flight application

Municipal Wastewater Treatment Plants: Conveying dewatered sludge from belt filter presses or centrifuges to storage or loading areas.

Headworks & Screening Areas: Transporting captured screenings (rags, wipes, plastics) from bar screens or fine screens to compactors or disposal containers.

Grit Removal Systems: Moving collected grit and sand from grit chambers or classifiers to washers or disposal points.

Sludge Thickening & Digestion: Handling and transferring thickened primary or secondary sludge between tanks and processes.

Industrial Pretreatment: Conveying semi-solid wastes, by-products, or screenings from food processing, pulp & paper, or chemical manufacturing facilities.

Pump Station & Lift Stations: Moving accumulated screenings and debris from wet wells to dumpsters for disposal.

Composting Facilities: Transporting and mixing organic waste and biosolids within composting tunnels or turning systems.

Marine & Offshore: Handling waste and bilge materials on ships and offshore platforms where reliable, clog-free operation is critical.

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China