Static screen wastewater description

Static screens are commonly used in facilities with low flowrates.

Major benefits are their simplicity, ease of operation and cost efficiency.

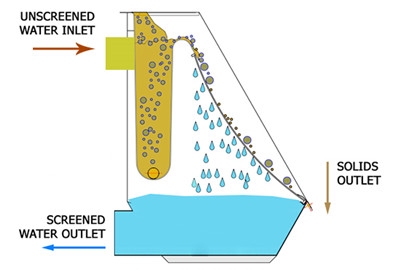

Continuous stream of wastewater falls on top the screen from above.

As the water flows through, solid waste is captured.

The impact of the constant flow from above drags previously captured screenings down and cleans the surface of the screen automatically.

Static screen wastewater works

Its operation is based on the Coandă effect. This means that the liquid to be screened forms a hydraulic attachment to the bars of the screen plate.

These bars, with triangular section, have rounded angles and have a wave configuration, as opposed to being straight.

Thus, the liquid passes through the slots while the separated solids stay on the front face of the screen plate.

The screen plate has three distinct angles.

This arrangement ensures:

Elimination of the majority of the liquid

Deceleration of the screenings

Drainage

The screen plate is supported by a frame which initially ensures quietness and even distribution of the effluent over the entire width of the unit and then accelerates the liquid

down the screen plate.

The filtered liquid is collected in the screen base.

The screen plate and the frame form the HydraSieve screen.

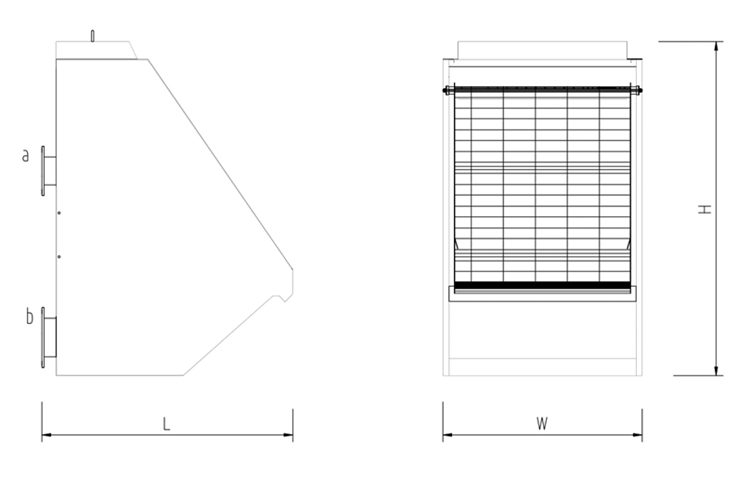

Static screen wastewater model

| HS Model |

Piping Connections Inlet(a) | Effluent(b) |

Physical Dimensions(m) L | W | H |

Weight (Kg) |

Capacities(m³/h) 0.5mm | 1mm | 1.5mm |

|---|---|---|---|---|

| HS-300 | 80 | 80 | 1.43 | 0.43 | 2 | 150 | 6 | 13 | 16 |

| HS-500 | 100 | 100 | 1.43 | 0.63 | 2 | 180 | 10 | 22 | 35 |

| HS-700 | 100 | 100 | 1.43 | 0.83 | 2 | 200 | 15 | 30 | 50 |

| HS-800 | 100 | 125 | 1.43 | 0.93 | 2 | 250 | 16 | 35 | 55 |

| HS-1000 | 150 | 150 | 1.43 | 1.13 | 2 | 280 | 20 | 45 | 70 |

| HS-1500 | 150 | 150 | 1.43 | 1.63 | 2 | 300 | 30 | 65 | 100 |

| HS-2000 | 200 | 200 | 1.43 | 2.13 | 2 | 400 | 40 | 75 | 120 |

Static screen wastewater advantage

1. No moving parts.

2. Low maintenance.

3. Wide range of applications.

4. Self cleaning.

Static screen wastewater feature

1. Make use of water flow gravity action , no energy consumption.

2. Large treating capacity of one unit.

3. No blocking , easy for maintenance.

4. The whole unit is made up of stainless steel , high mechanic strength.

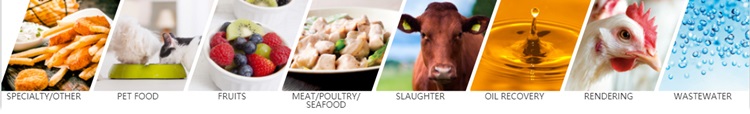

Static screen wastewater application

BAKERY

BREWERY

DAIRY

EGG

FRUIT

FOOD PROCESS

MEAT

MINERAL

MUNICIPAL

PETROCHEM

PHARMA

POULTRY

PULP & PAPER

SEAFOOD

SLUDGE THICKENING

VEGETABLE

WINERY

WASTEWATER

Name: Ashely Li

Mobile:+8613961861780

Tel:+8613961861780

Whatsapp:8613961861780

Email:info@dagyee.com

Add:Room 302, Building 11-4, Hongyi Road, Xinan Town, Xinwu District, jiangsu Province, China